The line wire feeding system consists of straightening wheels and pressure rollers.The straightening wheel can make the wire mesh flat, the mesh hole precise and the diagonal error small.

The function of the pressure roll is to make the whole wire mesh flat without distortion.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

FFI

-

Model Number:

-

FFI-GWC-3000G

-

Weight (KG):

-

7800

-

Power (kW):

-

720

-

Product name:

-

Expanded Metal Mesh Making Machine Wire Mesh Panel Welding Machine

-

Number of electrodes:

-

30

-

Mesh length:

-

3-12mm

-

Line wire space:

-

100-300mm

-

Cross wire space:

-

100-300mm

-

Electric capacity:

-

8*200KVA

-

Welding speed:

-

75times/min

-

Control system:

-

PLC

-

Material:

-

Low carbon steel wire,Galvanized wire, black wire

-

After-sales Service Provided:

-

Online support, Video technical support, Field installation, commissioning and training, Field maintenance and repair service

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

Quick Details

-

Wire Diameter (mm):

-

5 - 8 mm

-

Marketing Type:

-

Hot Product 2020

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

FFI

-

Model Number:

-

FFI-GWC-3000G

-

Weight (KG):

-

7800

-

Power (kW):

-

720

-

Product name:

-

Expanded Metal Mesh Making Machine Wire Mesh Panel Welding Machine

-

Number of electrodes:

-

30

-

Mesh length:

-

3-12mm

-

Line wire space:

-

100-300mm

-

Cross wire space:

-

100-300mm

-

Electric capacity:

-

8*200KVA

-

Welding speed:

-

75times/min

-

Control system:

-

PLC

-

Material:

-

Low carbon steel wire,Galvanized wire, black wire

-

After-sales Service Provided:

-

Online support, Video technical support, Field installation, commissioning and training, Field maintenance and repair service

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

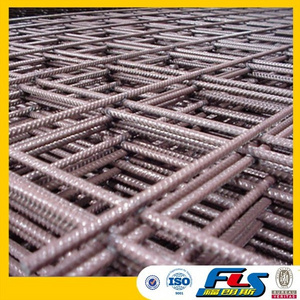

Steel Concrete Reinforcement Panel brc Reinforcement Mesh welding Making Machine

Products Description

This

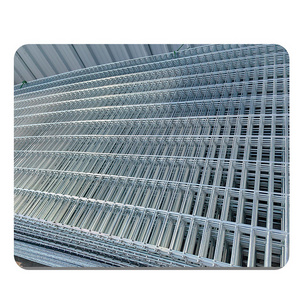

Automatic Steel Wire Mesh Machine Wire Mesh Panels Machine

is based on customer requirements and many years of production experience to upgrade and reform the entire production line.Its greatest advantages are high productivity, high automation and simple operation. Normal operation of the machine requires only one person to operate, the wire mesh panel products are smooth and beautiful, and the automatic stacking is neat. Save a lot of labor and space.

Product Paramenters

|

Item

|

Parameter

|

|

Number of electrodes

|

30

|

|

Max. mesh width

|

≤3000mm

|

|

Mesh length

|

3-12mm

|

|

Wire diameter

|

5-8mm

|

|

Line wire space

|

100-300mm

|

|

Cross wire space

|

100-300mm

|

|

Electric capacity

|

8*200KVA

|

|

Welding speed

|

75times/min

|

|

Control system

|

PLC

|

Features:

1.The vertical line feed is mainly composed of the payoff reel, the delay feeding rack, the cross straightening device, the line straightening device.

2.Main structure of welding machine mainly consists of rack, power system, welding system, line positioning device, cross alignment device.

3.Cross hopper for the double chain feeding hopper, divided into the upper hopper and the next hopper, can achieve different lengths of different wire diameter pre-cut wires automatic dropping

4.Anti-wire welding system consists of two sets of welding system and two sets of pre-cut wire feeding system, used to supplement the welding has been welded into the mesh on both sides of the opposite side of the line.

1.The vertical line feed is mainly composed of the payoff reel, the delay feeding rack, the cross straightening device, the line straightening device.

2.Main structure of welding machine mainly consists of rack, power system, welding system, line positioning device, cross alignment device.

3.Cross hopper for the double chain feeding hopper, divided into the upper hopper and the next hopper, can achieve different lengths of different wire diameter pre-cut wires automatic dropping

4.Anti-wire welding system consists of two sets of welding system and two sets of pre-cut wire feeding system, used to supplement the welding has been welded into the mesh on both sides of the opposite side of the line.

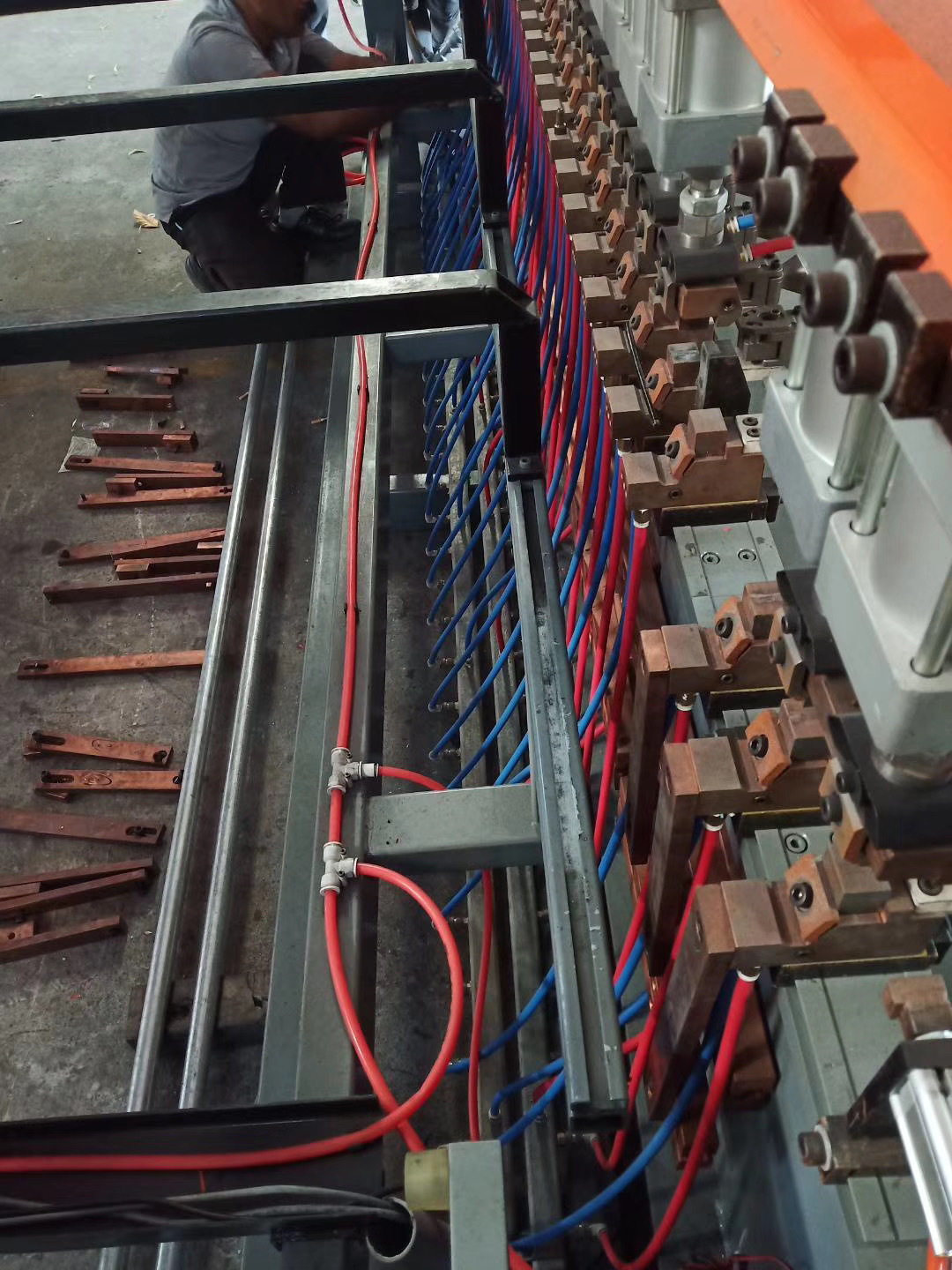

Details Images

Line wire feeding system

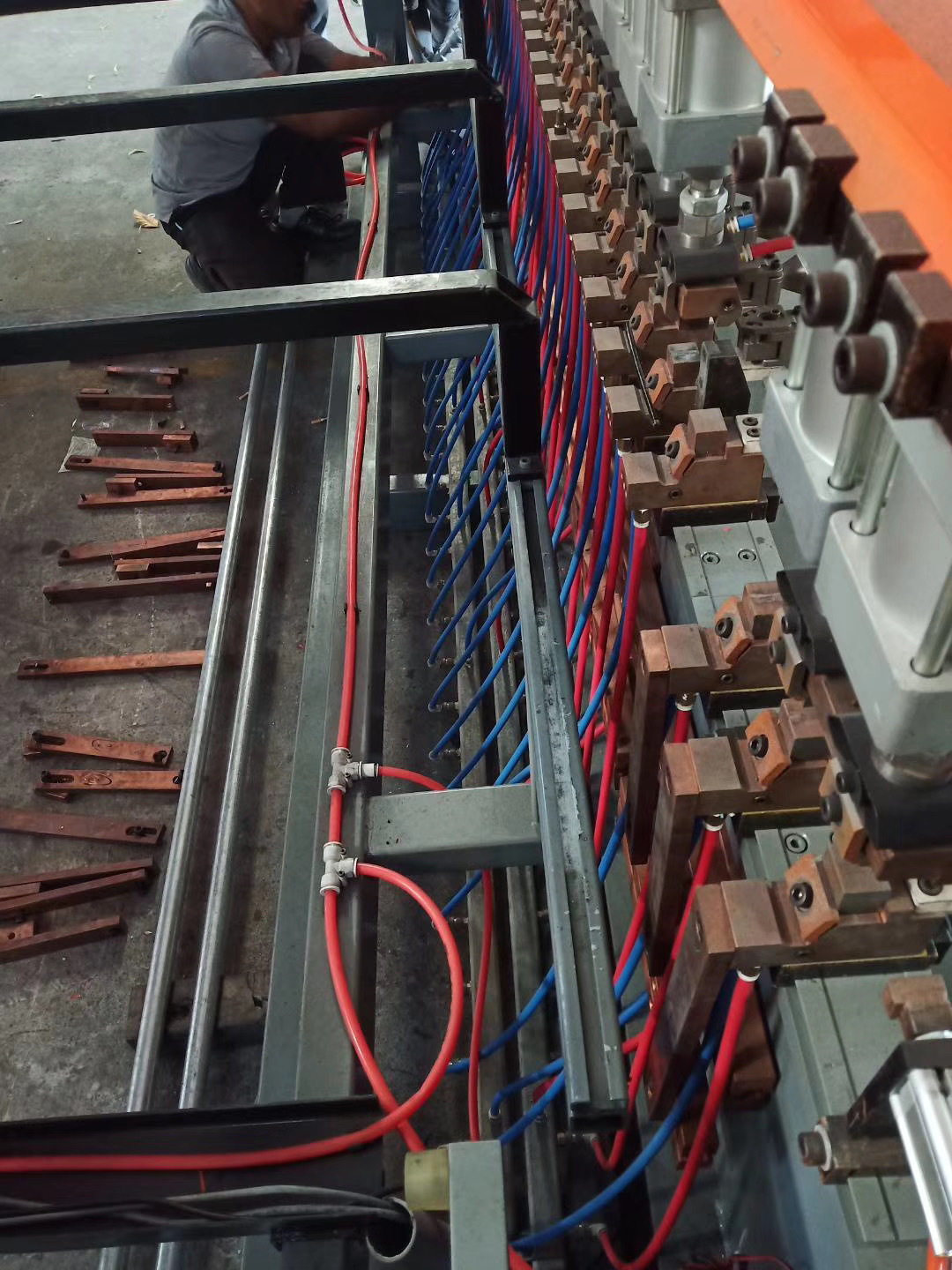

Mesh Welding System

Mesh welding system for fully automatic

production,

the machine adopts synchronous and PLC control technique. The welding power comes from the spring. At the same time, the below welding electrodes are equipped with water cooling welding system to make sure the welding quality and prolong the life.

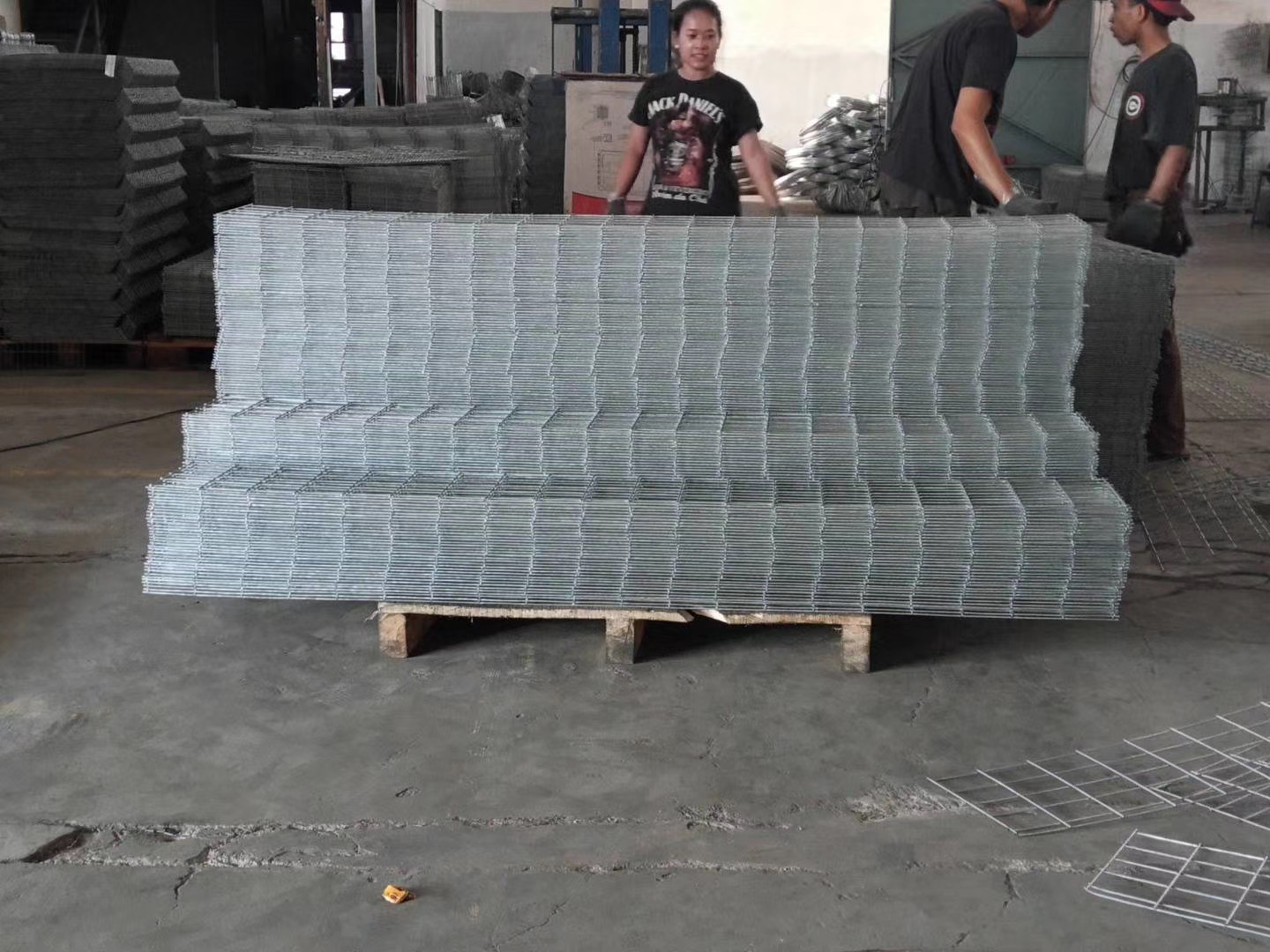

Packing And Delivery

Best Automatic Steel Wire Mesh Machine Wire Mesh Panels Machine for sale

Hot Searches