- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

IWIN

-

Model Number:

-

IWIN-STS

-

Product name::

-

Concrete Slump Cone Test Apparatus for Workability

-

Operating way::

-

Manual

-

Up diameter::

-

100mm

-

Weight::

-

8kg

-

Keywords::

-

Concrete slump test

-

Material::

-

Coated steel

-

Usage range::

-

in field or lab

-

Bottom diameter::

-

200mm

-

Slump High::

-

300mm

Quick Details

-

Warranty:

-

1 year

-

Power:

-

non

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

IWIN

-

Model Number:

-

IWIN-STS

-

Product name::

-

Concrete Slump Cone Test Apparatus for Workability

-

Operating way::

-

Manual

-

Up diameter::

-

100mm

-

Weight::

-

8kg

-

Keywords::

-

Concrete slump test

-

Material::

-

Coated steel

-

Usage range::

-

in field or lab

-

Bottom diameter::

-

200mm

-

Slump High::

-

300mm

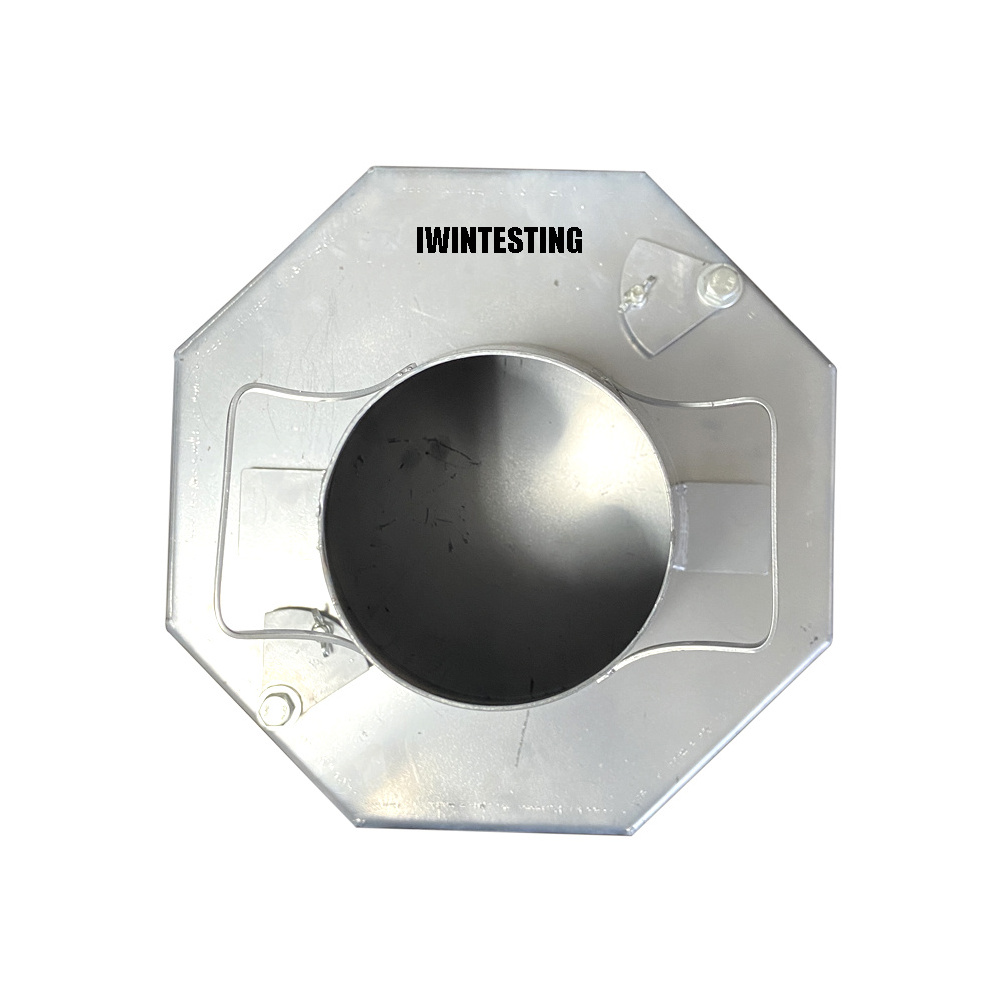

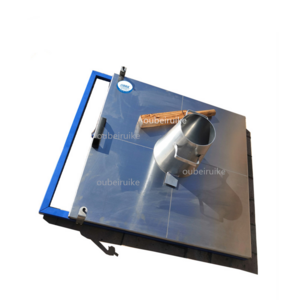

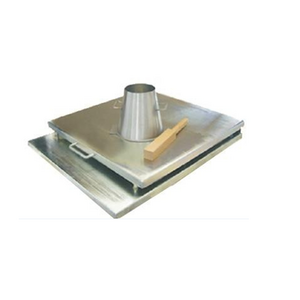

Concrete Slump Cone Test Apparatus for Workability

Product Description

These portable slump test sets consist of a steel slump cone, tamping rod, and cast-aluminum test base with handle for easy transportation.

Procedure for Concrete Slump Cone Test

- Clean the internal surface of the mould and apply oil.

- Place the mould on a smooth horizontal non- porous base plate.

- Fill the mould with the prepared concrete mix in 4 approximately equal layers.

- Tamp each layer with 25 strokes of the rounded end of the tamping rod in a uniform manner over the cross section of the mould. For the subsequent layers, the tamping should penetrate into the underlying layer.

- Remove the excess concrete and level the surface with a trowel.

- Clean away the mortar or water leaked out between the mould and the base plate.

- Raise the mould from the concrete immediately and slowly in vertical direction.

- Measure the slump as the difference between the height of the mould and that of height point of the specimen being tested.

Hot Searches