In our company, various packing methods are adopted according to different product features, such as bubble wrap, color box or brown box in carton, pallet, wooden case etc. For

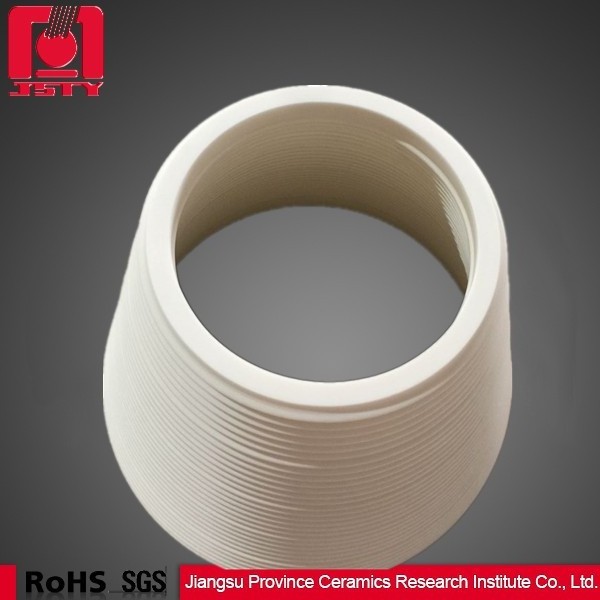

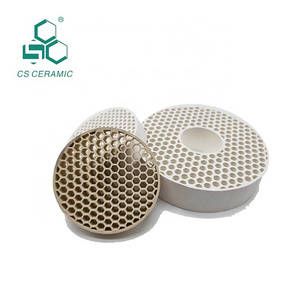

White alumina ceramic taper sleeve industrial ceramic

, we can discuss it together and choose the most suitable one.

As for shipment, different ways have their own advantage and disadvantage:

By Ship: the cheapest, suitable for large amounts take more time

By Air: faster, more convenient a little bit expensive

By Express: more flexiable, door to door much more expensive

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

OEM

-

Product Name:

-

White alumina ceramic taper sleeve industrial ceramic

-

Color:

-

White

-

Certificate:

-

ISO9001:2001

-

Packing:

-

Wooden case or caton

-

Main Porformance:

-

Good wear, corrosion, heat resistant, high breakdown strength

-

Size:

-

Dia350x70, 330x100, 330x300mm

-

Density:

-

3.6-3.85g/cm3

-

History:

-

58 years experience in ceramic field

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

Jiangsu, China

-

Model Number:

-

Alumina Ceramic Sheet

-

Brand Name:

-

OEM

-

Product Name:

-

White alumina ceramic taper sleeve industrial ceramic

-

Color:

-

White

-

Certificate:

-

ISO9001:2001

-

Packing:

-

Wooden case or caton

-

Main Porformance:

-

Good wear, corrosion, heat resistant, high breakdown strength

-

Size:

-

Dia350x70, 330x100, 330x300mm

-

Density:

-

3.6-3.85g/cm3

-

History:

-

58 years experience in ceramic field

Video Description

Products Description

Product Details

Technical data of

White alumina ceramic taper sleeve industrial ceramic

:

-Heat resistance

-Wear resistance

-High strengh

-Good insulation

-Corrosion resistance

-Used in all electric products, electric heating products and wear resistant machinery parts.

-OEM, ODM and OBM are welcomed

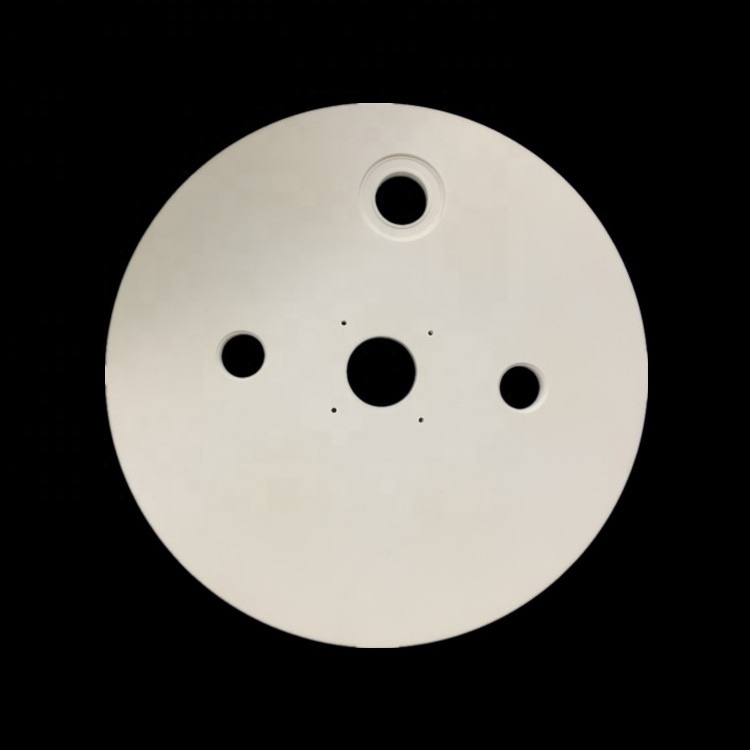

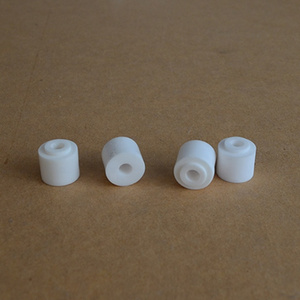

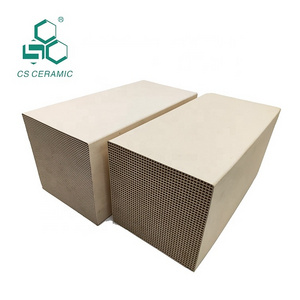

Our industrial ceramic parts include tube, rod, plate, disc, wafer, ring, seal, bearing, valves, pump plunger, beam, roller,

shaft, screw, washer, sleeve, hunger, spacer, holder, carrier, insulator, fixture, clamp, chuck, nozzle, guide, frame, lining, and

grinding media, milling ball or beads besides good performance own research electrodialysis membrane stack.

These precision toleranced ceramic components or assemblies are used in a wide range of semiconductor, electronic,

electrical,mechanical, chemical, automotive, textile and the other industrial engineering applications, due to their extreme

hardness, more resistances to wear, heat,corrosion, high electric insulation, and low thermal expansion.

From life-extending elements to next-generation, renewable energy products, Jiangsu Province Ceramics Research Institute Co., Ltd genuinely helps make the world measurably better. We work with engineers and designers like you to develop tomorrow’s technology and art for just what you search for in the global economy.

Using our core strengths of custom-engineering & designing, material expertise, operational excellence and rapid execution. We help our customers develop amazing solutions about tableware & fine ceramics.

Our experienced designing, engineering, manufacturing, exporting experts are ready to help with your next project.

shaft, screw, washer, sleeve, hunger, spacer, holder, carrier, insulator, fixture, clamp, chuck, nozzle, guide, frame, lining, and

grinding media, milling ball or beads besides good performance own research electrodialysis membrane stack.

These precision toleranced ceramic components or assemblies are used in a wide range of semiconductor, electronic,

electrical,mechanical, chemical, automotive, textile and the other industrial engineering applications, due to their extreme

hardness, more resistances to wear, heat,corrosion, high electric insulation, and low thermal expansion.

From life-extending elements to next-generation, renewable energy products, Jiangsu Province Ceramics Research Institute Co., Ltd genuinely helps make the world measurably better. We work with engineers and designers like you to develop tomorrow’s technology and art for just what you search for in the global economy.

Using our core strengths of custom-engineering & designing, material expertise, operational excellence and rapid execution. We help our customers develop amazing solutions about tableware & fine ceramics.

Our experienced designing, engineering, manufacturing, exporting experts are ready to help with your next project.

Echnical Parameters

|

ITEM

|

UNIT

|

AL2O3(95-97)

|

AL2O3(99)

|

|

DESITY

|

g/cm3

|

3.7

|

3.85

|

|

FLEXURAL STRENGTH

|

Mpa

|

300

|

340

|

|

COMPRESSIVE STRENGTH

|

Mpa

|

3400

|

3600

|

|

MODULUS OF ELASLICITY

|

Gpa

|

350

|

380

|

|

IMPACT RESISTANCE

|

Mpa m(1/2)

|

4

|

5

|

|

WEIBULL MOUDULUS

|

m

|

10

|

10

|

|

VICKERS HARDNESS

|

HV0.5

|

1200

|

1300

|

|

THERMAL EXPANSION COEFFICENT

|

10(-6)K(-1)

|

5.0-8.3

|

5.4-8.3

|

|

THERMAL CONDUCTIVITY

|

W/mK

|

24

|

27

|

|

THERMAL SHORK RESISTANCE

|

Δ T℃

|

250

|

270

|

|

MAXIMUM USE TEMPERATURE

|

℃

|

1600

|

1650

|

|

VOLUME RESISTIVITY AT 20℃

|

Ω

|

≥10(14)

|

≥10(14)

|

|

DIELECTRIC CONSTANT

|

KV/mm

|

20

|

25

|

|

OPEN POROSITY

|

%

|

0

|

0

|

|

DIELECTRIC CONSTANT

|

|

|

|

|

DIELECTRIC LOSS ANGLE

|

Tanб

|

0.001

|

0.001

|

|

ITEM

|

UNIT

|

AL2O3(95-97)

|

AL2O3(99)

|

|

DESITY

|

g/cm3

|

3.7

|

3.85

|

|

FLEXURAL STRENGTH

|

Mpa

|

300

|

340

|

|

COMPRESSIVE STRENGTH

|

Mpa

|

3400

|

3600

|

|

MODULUS OF ELASLICITY

|

Gpa

|

350

|

380

|

|

IMPACT RESISTANCE

|

Mpa m(1/2)

|

4

|

5

|

|

WEIBULL MOUDULUS

|

m

|

10

|

10

|

|

VICKERS HARDNESS

|

HV0.5

|

1200

|

1300

|

|

THERMAL EXPANSION COEFFICENT

|

10(-6)K(-1)

|

5.0-8.3

|

5.4-8.3

|

|

THERMAL CONDUCTIVITY

|

W/mK

|

24

|

27

|

|

THERMAL SHORK RESISTANCE

|

Δ T℃

|

250

|

270

|

|

MAXIMUM USE TEMPERATURE

|

℃

|

1600

|

1650

|

|

VOLUME RESISTIVITY AT 20℃

|

Ω

|

≥10(14)

|

≥10(14)

|

|

DIELECTRIC CONSTANT

|

KV/mm

|

20

|

25

|

|

OPEN POROSITY

|

%

|

0

|

0

|

|

DIELECTRIC CONSTANT

|

|

|

|

|

DIELECTRIC LOSS ANGLE

|

Tanб

|

0.001

|

0.001

|

Click on the photos below for more products information

Certifications

Exhibition

Product packaging

Factory View

1. Tableware : Auto-molding production line, Glaze decorating production line, Finished product inspection line in

order to make perfert general ceramic for you.

2. Industrial ceramics: Iso-static pressing equipment, Auto-pressing machines in PTC production, Continuous kiln,

CNC(Computer numerical control machining centre). Every step is sesured to make sure quality of every White alumina ceramic taper sleeve industrial ceramic .

3. Test equipments: Composition analyzer, Strength Tester, Light microscope, Thermal expansion coefficient tester.

order to make perfert general ceramic for you.

2. Industrial ceramics: Iso-static pressing equipment, Auto-pressing machines in PTC production, Continuous kiln,

CNC(Computer numerical control machining centre). Every step is sesured to make sure quality of every White alumina ceramic taper sleeve industrial ceramic .

3. Test equipments: Composition analyzer, Strength Tester, Light microscope, Thermal expansion coefficient tester.

FAQ

1. How can I get an offer?

You can send your drawing with technology requirements and mark your purchase quantity of White alumina ceramic taper sleeve industrial ceramic . It is much better if you could offer the usage information about products.

We will confirm the most suitable material and quote our best price to you in 24 hours.

2. Can you accept OEM & ODM?

Yes, we can produce the products according to your demand and drawing.

3. Can you provide free samples?

Yes, we can provide the sample for free, but the freight and mold fee are on your side.

4. What’s the lead-time for samples?

Within 3-7 days for bulk order, 15-45 days for OEM designs and shapes.

5. What’s your production Lead-time for bulk order?

Generally it takes 30-45 days and 45-60 days in peak season.

6. What are your payment terms?

In generally, we quote FOB Shanghai price, payment 30% deposit by T/T in advance, 70% balance paid before shipment

or within 7 days against shipping documents.

It balances against Weston Union, L/C or Paypal etc. (Payment about White alumina ceramic taper sleeve industrial ceramic can be negotiated, kindly to contact with us)

You can send your drawing with technology requirements and mark your purchase quantity of White alumina ceramic taper sleeve industrial ceramic . It is much better if you could offer the usage information about products.

We will confirm the most suitable material and quote our best price to you in 24 hours.

2. Can you accept OEM & ODM?

Yes, we can produce the products according to your demand and drawing.

3. Can you provide free samples?

Yes, we can provide the sample for free, but the freight and mold fee are on your side.

4. What’s the lead-time for samples?

Within 3-7 days for bulk order, 15-45 days for OEM designs and shapes.

5. What’s your production Lead-time for bulk order?

Generally it takes 30-45 days and 45-60 days in peak season.

6. What are your payment terms?

In generally, we quote FOB Shanghai price, payment 30% deposit by T/T in advance, 70% balance paid before shipment

or within 7 days against shipping documents.

It balances against Weston Union, L/C or Paypal etc. (Payment about White alumina ceramic taper sleeve industrial ceramic can be negotiated, kindly to contact with us)

Hot Searches