- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Lever

-

Voltage:

-

380V

-

Power:

-

530KW

-

Dimension(L*W*H):

-

20403 * 5700 * 3500mm

-

Weight:

-

40000KGS

-

Glass Application:

-

Architecture, Furniture, Automobile, Household Appliance etc

-

Max. loading glass size:

-

2000*3000mm

-

Max. curved glass size:

-

2000*1200mm

-

Min. loading size:

-

150*250mm

-

Glass thickness:

-

4mm-19mm

-

PLC:

-

Siemens

-

Glass can be temperd:

-

Low-E glass,clear glass,tinted glass,pattern ,screen printed glass

-

Machine Usage:

-

Make Tempered Toughened safety Glass

-

Blower Power:

-

250KW

Quick Details

-

Machine Type:

-

Glass Tempering Furnace

-

Glass Thickness:

-

Other

-

Production Capacity:

-

98%

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Lever

-

Voltage:

-

380V

-

Power:

-

530KW

-

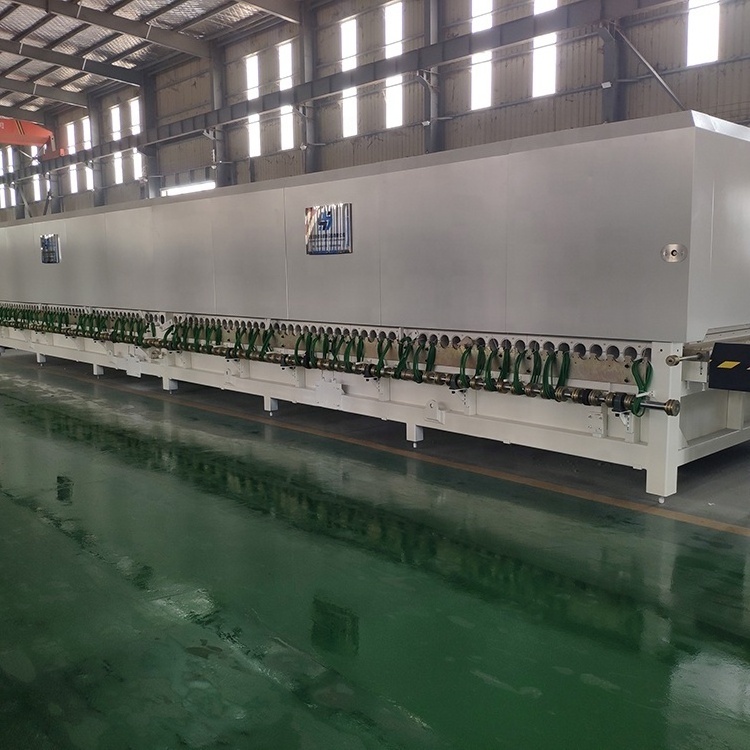

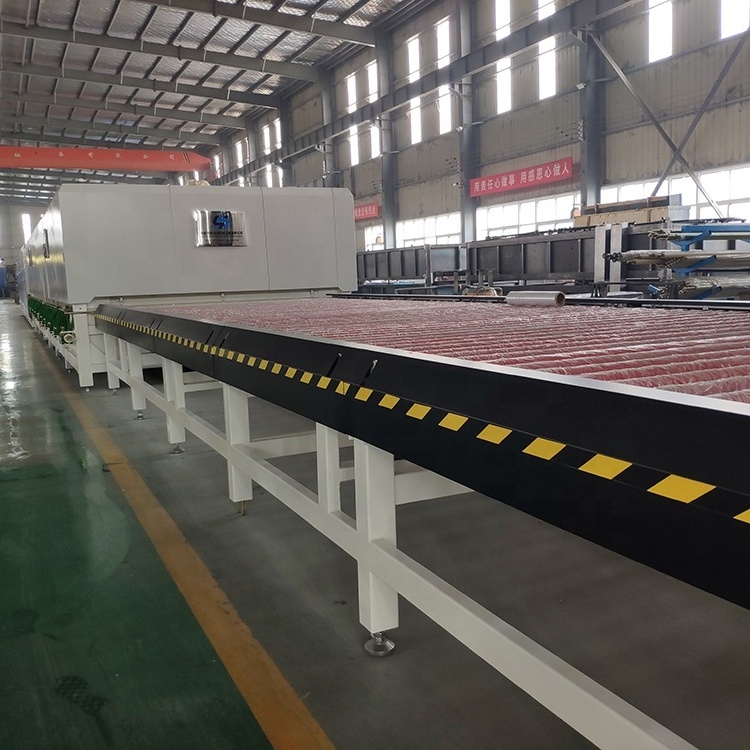

Dimension(L*W*H):

-

20403 * 5700 * 3500mm

-

Weight:

-

40000KGS

-

Glass Application:

-

Architecture, Furniture, Automobile, Household Appliance etc

-

Max. loading glass size:

-

2000*3000mm

-

Max. curved glass size:

-

2000*1200mm

-

Min. loading size:

-

150*250mm

-

Glass thickness:

-

4mm-19mm

-

PLC:

-

Siemens

-

Glass can be temperd:

-

Low-E glass,clear glass,tinted glass,pattern ,screen printed glass

-

Machine Usage:

-

Make Tempered Toughened safety Glass

-

Blower Power:

-

250KW

Main Features

1). The process for glass curvature forming is controlled by computer. You can input the needed radius data to computer, then required glass will be produced accordingly. But some time, for the new radius, you should make some mini-adjustment manually at the first time. This section is suitable to process 3.2mm automotive car side door glasses.

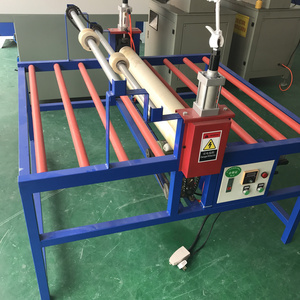

2). Materials: aluminum-alloy wheel with fiber rope

3). As separated structure, the cooling quench for bent tempering are fixed among the rollers and made actions for deformation accordingly. The cooling air is blown in from the grid back through heat resistant soft hose.4). Without any mold. The forming method is automatic quench transmutation.

5). Fixed length swinging and reciprocating swinging during the whole process

6). There is sensor for glass length measuring.

7). It is very easy to change the glass with different thickness or radius.

Hot Searches