- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

200*100*60 mm, 150*150*100 mm, 230*220*115 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GiantLin Machinery

-

Voltage:

-

220V/380V/440V

-

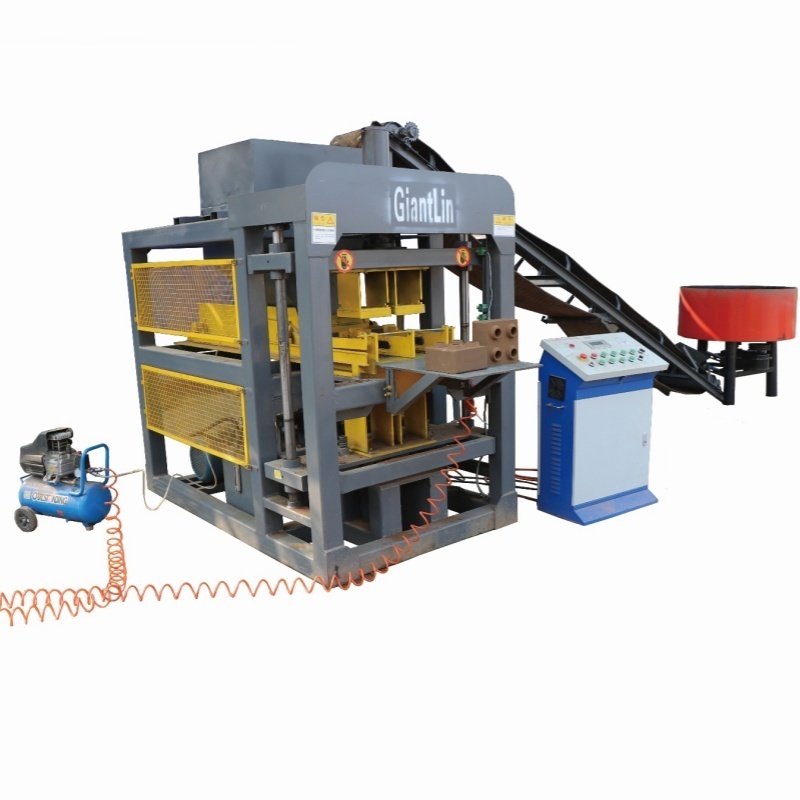

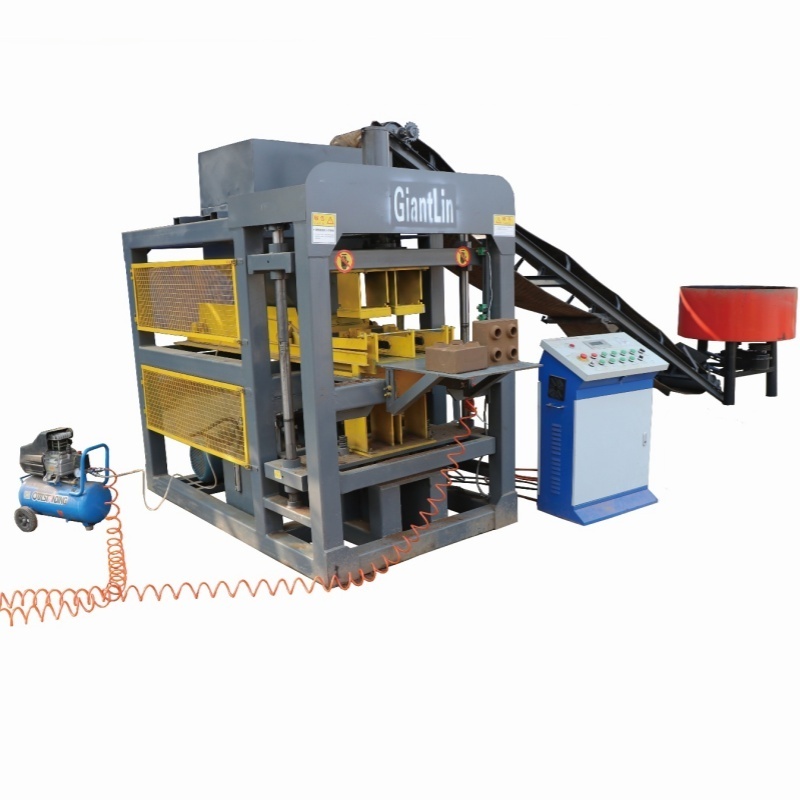

Dimension(L*W*H):

-

2250*1620*2200mm

-

Weight (KG):

-

2000 kg

-

Raw material:

-

soil, clay, earth, cement, sand

-

Block Type:

-

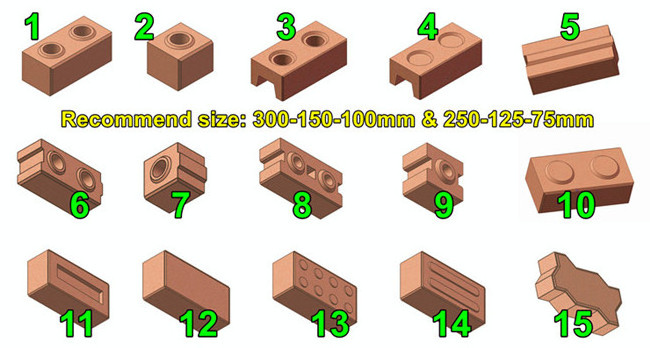

different designs of interlocking blocks and bricks

-

Molding cycle:

-

10 seconds

-

Capacity:

-

2 bricks in one time, 5760 bricks in one day

-

Workers Number:

-

4-5 Workers

-

Weight:

-

2000KGS

-

Color:

-

Designated Color

-

Press:

-

20THydraulic Press

-

Warrantee:

-

2 yeas

Quick Details

-

Type:

-

Interlock Block Making Machine

-

Brick Raw Material:

-

Clay

-

Production Capacity (Pieces/8 hours):

-

14400 bricks in one day

-

Brick size:

-

200*100*60 mm, 150*150*100 mm, 230*220*115 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GiantLin Machinery

-

Voltage:

-

220V/380V/440V

-

Dimension(L*W*H):

-

2250*1620*2200mm

-

Weight (KG):

-

2000 kg

-

Raw material:

-

soil, clay, earth, cement, sand

-

Block Type:

-

different designs of interlocking blocks and bricks

-

Molding cycle:

-

10 seconds

-

Capacity:

-

2 bricks in one time, 5760 bricks in one day

-

Workers Number:

-

4-5 Workers

-

Weight:

-

2000KGS

-

Color:

-

Designated Color

-

Press:

-

20THydraulic Press

-

Warrantee:

-

2 yeas

SYN2-5 automatic hydraulic compressed earth clay interlocking lego brick machine price

A: 20 Ton Hydraulic Press, High Strength of Interlocking Brick and pavers

B: 2 Bricks in one time and 5760 bricks in 8 hours

C : Automatic PLC Operation

D: Producing Designs of interlocking bricks, hydraform block and pavers by changing molds

E: Suitable for Large-scale Block Factory

F : Professtional manufacturer produce any designs of molds you want

SYN2-5 lego brick making machine can produce designs of interlocking lego bricks, hydraform blocks and interlocking pavers by changing molds.

1: Electric Power List for SYN2-5 automatic hydraulic compressed earth clay interlocking lego brick machine price

| Item | Name | Power | Function |

|---|---|---|---|

| A |

3M Belt Conveyor |

0.75 |

Carry soil into soil crusher |

| B | Soil Crusher | 5.5KW | Crush soil into find soil |

| C | 3M Belt Conveyor |

0.75 |

Carry soil from soil crusher to soil screen |

| D | Soil Screen | 1.1KW | Select fine soil |

| E | 3M Belt Conveyor | 0.75KW |

Carry fine soil from soil screen to mixer |

| F | JQ500 Mixer | 7.5KW |

Mix soil, cement and water |

| G | 5M Belt Conveyor | 0.75KW |

Carry Mixed material from Mixer to Brick Machine |

| H | SYN5-5 Brick Machine | 15KW |

Produce designs of interlocking brick with molds |

| I | Brick Receiver | 0.75KW |

Carry fresh bricks from brick machine |

| Total: SYN2-5 brick making line total power:32.85kw Electricty must be 3 phase, 50/60HZ, 220/380/440V | |||

1. Workers number for SYN2-5 automatic brick making line: 5 Workers in total.

One worker for loading soil to A : Belt conveyor for crushing

One Worker for loading cement and water into F : JQ500 Mixer

One worker for operating H : Brick Machine

Two Worker for Carrying Fresh brick from I: brick receiver to curing site

2. Factory Area :1500-2000 M2

Shelter Area for machines: 60M2 (10*6m)

3. Material Ratio for Bricks: 5%-10% cement and 90%-95% soil

4. Raw Material Consumption in one day

Here we take 300*150*100mm bricks as example and recommend 8% cement.

|

Size of Brick |

300*150*100mm |

|

Material Ratio |

8% cement and 92% soil |

|

Strength of Brick |

6-7Mpa |

|

Capacity of Brick |

14400 bricks in one day |

|

Consumption of Cement |

6912 KG per day |

|

Consumption of Soil |

79488 kg per day |

5: Install Service: We will supply customers manual and install video and we will can send our engineer to customers place to help customer install machine and train workers

6. How to Curing Bricks: Fresh Bricks are stacked and covered with black plastic to avoid moisture loss. The bricks are then watered daily to create a greenhouse effect, allowing the cement to harden and the bricks to strengthen. Cure your Bricks for a minimum of 7 days and allow the Bricks to dry for another 7 days before building. This will ensure strong good quality Bricks

| Company Website : www.GiantLinMachinery.com |

How to find your suitable block machine fast,please click here: