1.Application: Cardboard, books, calendars, PVC film ETC.

2.Inspection: Lackpage auto feeding,multipage auto removing.

3.Multifunction:Connected with the book collection, stitching, folding, and trimming machines.

4.Warning: Each station is equipped with alerting system.

5.Station Control: Each station independently controlled,any station can work separated.

Advantage

1.Control system adopt global brands(PLC,Intelligent sensor,Electronic control unit ,etc.)

2.The machine can work for the single paper or the folded paper, even mixed the thin and thick paper.

3.Machine frame adopt strong and high precision steel; Spare parts are made of high quality materials; Standard parts are all

international brands, with quality guarantee and good exchange ability.

4.The program is simple and easy to operate;The control system is perfect and stable ,excellent editing and extensibility.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Koten

-

Voltage:

-

330V

-

Dimension(L*W*H):

-

7100*1550*1920mm

-

Weight:

-

3600 kg

-

Marketing Type:

-

Hot Product 2023

-

PLC Brand:

-

Zmotiom

-

Paper Thickness Range:

-

40-1000 gsm

-

Working Stastion:

-

8,13,15,16

-

Max. Speed:

-

2800pcs/h

Quick Details

-

Type:

-

Gathering Machine

-

Production Capacity:

-

2800pcs/h

-

Max. workable width:

-

380mm

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Koten

-

Voltage:

-

330V

-

Dimension(L*W*H):

-

7100*1550*1920mm

-

Weight:

-

3600 kg

-

Marketing Type:

-

Hot Product 2023

-

PLC Brand:

-

Zmotiom

-

Paper Thickness Range:

-

40-1000 gsm

-

Working Stastion:

-

8,13,15,16

-

Max. Speed:

-

2800pcs/h

Product Description

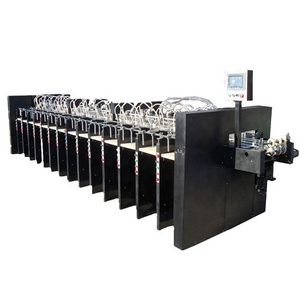

Horizontal Automatic Gathering Machine

PY80

Details Images

Screen

10 inches screen with big icons which is easy to operate.

Humanized software interface, perfect functions, efficient control.

Waste Unit

High-speed motor control to meet the speed requirements of different production lines;

Automatic removal of defective products and collection; Stainless steel mirror transition table, will not damage the product, can be used again.

Stitching Head

Two pieces HOHNER stitching head from Germany Model 43/6

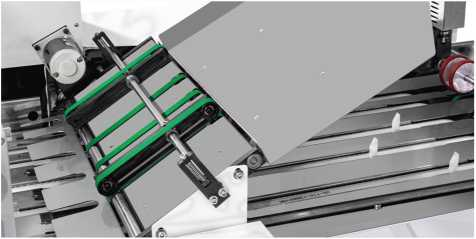

Feeder

Feeders are the same size can be changed.

Feeders are controlled by the synchronous gear, working stable;

The distance between the sunction and the paper can be adjusted.

Lifting Platform

The feeding unit with the electric lifting frame, equipped with the front and side blowing group;

Equipped with the upper and lower limit switches to detect paper height so that can feeding automatic.

The lifting is driven by chain which work stable.

Wooden table to avoid static electricity.

Main Parameters

13 Stations Gathering Machine

|

Max. Paper Size

|

480*320mm (Supporting customization)

|

|

Min. Paper Size

|

100mm*120mm

|

|

Paper Thickness Range

|

40-1000 gsm

|

|

Working Stastion

|

8,13,15,16 (Supporting customization)

|

|

Max.Paper Stacking Height

|

600mm

|

|

Max. Speed

|

2800pcs/h

|

|

Weight

|

3600kgs

|

|

Power

|

6.8KW

|

|

Machine Dimensions

|

7100*1550*1920mm

|

|

Feeding System

|

Flat Feeding

|

|

Feeder nunmber

|

13

|

|

Materials

|

Offset paper, carbon free paper, Coated paper,etc.

|

Stitching,Floding and Front Cutting Machine

|

Max. Paper Size

|

480*320mm

|

|

Min. Paper Size

|

120*120mm

|

|

Finished Product Size

|

120* 60mm--220*300mm

|

|

Paper Thickness Range

|

40-350gsm

|

|

Max. Stitching Speed

|

5000 pcs/hour

|

|

Folding Way

|

Single knife

|

|

Range of Trimming

|

1-5mm

|

|

Stitching Heads Quantity

|

2pcs

|

|

Weight

|

100kgs

|

|

Power

|

1KW

|

|

Machine Dimensions

|

1450*3400*1550mm

|

|

Feeding System

|

Flat Feeding

|

Collecting Machine

|

Max./Min. Product(mm)

|

480*320 / 100*120

|

|

Max.Paper Stacking Height

|

400mm

|

|

Paper Thickness Range

|

0.1mm-30mm

|

|

Feeding System

|

Flat feeding and split the book left and right

|

|

Alarm System

|

Paper jam problem ( indicate fault location)

|

|

Collecting system

|

Automatic transfer

|

|

Power

|

0.8KW

|

|

Weight

|

100kgs

|

|

Machine Dimensions

|

1300*600*1050mm

|

Configuration list

Gathering Machine

|

Name

|

Brands

|

Quantity

|

|

Touch Screen

|

Zmotion(China)

|

1

|

|

Servo Motor

|

LEAD-motion(Germany)

|

4

|

|

AC Motor

|

JSCC(Taiwan China)

|

13

|

|

Induction Block

|

SICK (Germany)

|

3

|

|

Induction Block

|

Biduk(China)

|

13

|

|

Encoder

|

OMRON(Japan)

|

1

|

|

Blower

|

Sensen (China)

|

4

|

|

Vacuum Pump

|

BECKER(Germany)

|

1

|

|

Solenoid Valve

|

AIRTAC(Taiwan China)

|

28

|

|

PLC

|

Zmotiom(China)

|

1

|

Stitching,Floding and Front Cutting Machine

|

Name

|

Brands

|

Quantity

|

|

Inverter

|

Schneider (France)

|

2

|

|

Stepper Driver

|

Schneider (France)

|

3

|

|

Power Supply

|

MeanWell(Taiwan China)

|

1

|

|

PLC

|

Schneider (France)

|

1

|

|

Air Cylinder

|

AIRTAC(Taiwan China)

|

2

|

|

Relay

|

IDEC (Japan)

|

16

|

Collecting Machine

|

Name

|

Brands

|

Quantity

|

|

Touch Screen

|

Tongtai (China)

|

1

|

|

Induction Block

|

Omron (Japan)

|

2

|

|

Servo Motor

|

Reiter (China)

|

1

|

|

Air Cylinder

|

AIRTAC(Taiwan China)

|

2

|

|

PLC

|

Junchuang (China)

|

1

|

Application

Hot Searches