- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

DL Sand Molding Machine

-

Voltage:

-

380V 50HZ

-

Power:

-

10 KW

-

Dimension(L*W*H):

-

2960*2100*2800MM

-

Weight (KG):

-

15000

-

Type:

-

Auto Sand molding machine

-

The Size Of Sand Mold:

-

300 * 400 / 350 * 400 / 350 * 450 ( mm )

-

The Thickness Of Sand Mold:

-

( 80~150 ) * 2 ( mm )

-

The Speed Of Manufacturing Mold:

-

28 sec / mold

-

Compaction Pressure:

-

not more than ( 40 - 80 ) kg

-

Air Comsumption ( Normal / Mold):

-

0.3 cubic meter

-

Machine Total Power:

-

10 kw

-

Humidity Of Sand Mold:

-

2.5 % ~ 3 %

-

The Thickness Of Template:

-

15 ~ 25 mm

-

After Warranty Service:

-

Field maintenance and repair service

Quick Details

-

Place of Origin:

-

Fujian, China

-

Machine Type:

-

casting molding machine

-

Marketing Type:

-

casting molding machine

-

Brand Name:

-

DL Sand Molding Machine

-

Voltage:

-

380V 50HZ

-

Power:

-

10 KW

-

Dimension(L*W*H):

-

2960*2100*2800MM

-

Weight (KG):

-

15000

-

Type:

-

Auto Sand molding machine

-

The Size Of Sand Mold:

-

300 * 400 / 350 * 400 / 350 * 450 ( mm )

-

The Thickness Of Sand Mold:

-

( 80~150 ) * 2 ( mm )

-

The Speed Of Manufacturing Mold:

-

28 sec / mold

-

Compaction Pressure:

-

not more than ( 40 - 80 ) kg

-

Air Comsumption ( Normal / Mold):

-

0.3 cubic meter

-

Machine Total Power:

-

10 kw

-

Humidity Of Sand Mold:

-

2.5 % ~ 3 %

-

The Thickness Of Template:

-

15 ~ 25 mm

-

After Warranty Service:

-

Field maintenance and repair service

3. Highly standardized, good parts interchangeable, fast and low-cost maintenance

4. The sand could be compacted both inside and outside according to technical

requirements, which makes the sand mold better.

5. Mold release agent is sprayed automatically, which makes the demolding smooth.

casting surface glossily, and no defect in the sand mold.

6. Electric cabinets and hydraulic stations are all installed in the machine, which makes

them compact and easy maintenance.

7. Low failure rate and the machine can diagnose the failure on its own.

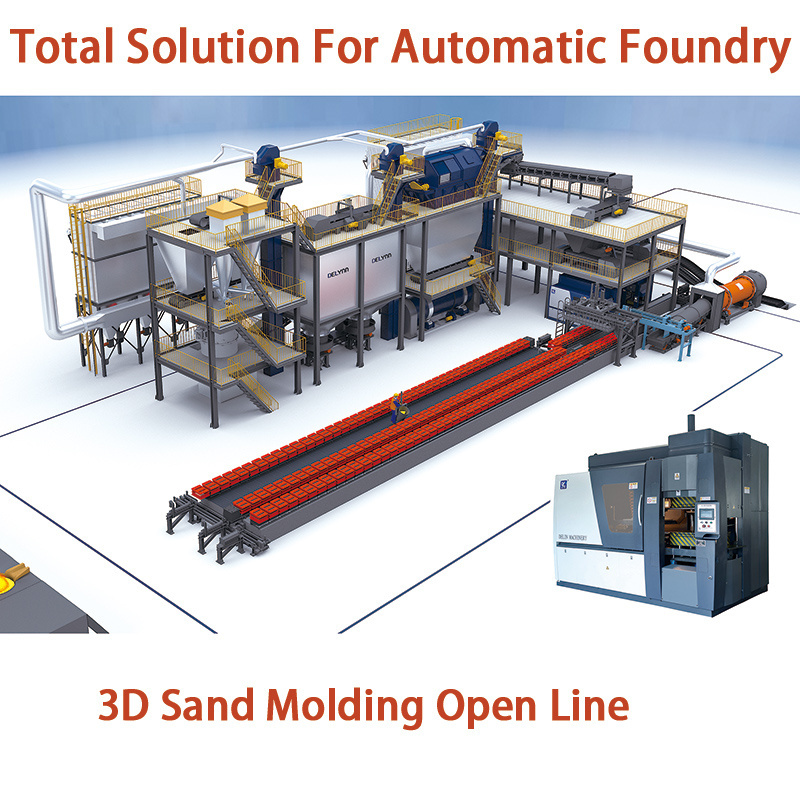

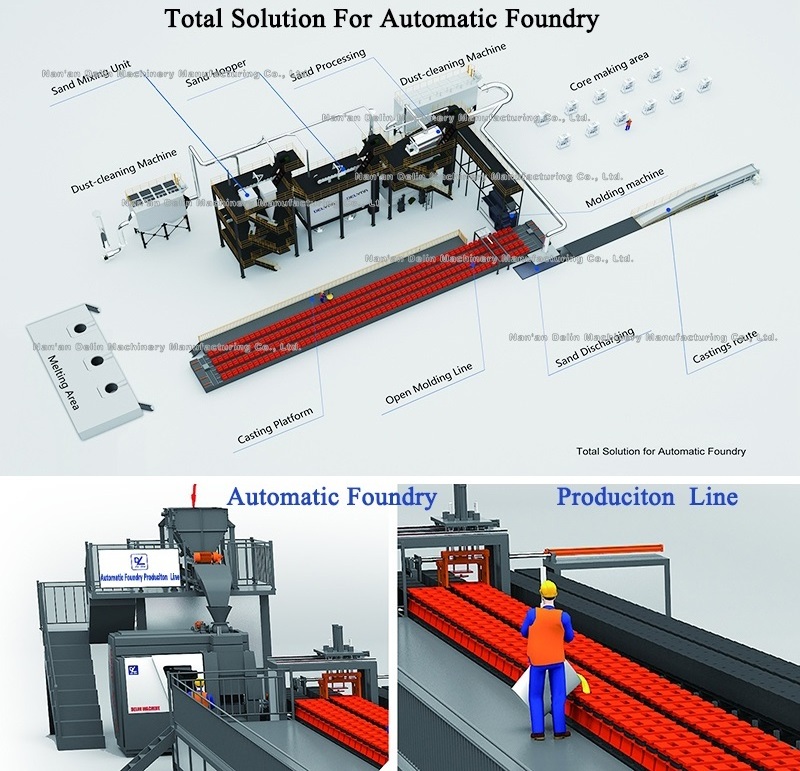

Ferrous and non-ferrous metal foundry production series

We have the whole foundry production line machinery, which is widely used to make and process plumbing, sanitaryware, car spares, valves, iron cast lines, and so on.

Main equipment: automatic SPM machining equipment, such as horizontal CNC drilling/milling/tapping machine; Double head drilling and tapping machine, automatic sand molding machine, low-pressure die casting machine, gravity casting machine, furnace, core shooting machine, mixing sand machine, shot blasting machine, polishing machine, etc.