- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LC

-

Model Number:

-

H-TC50SA

-

Usage:

-

Cosmetic case, soft tube, Tube Printer

-

Weight:

-

1590 KG

-

Platen Size:

-

20*30cm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

white:

-

steel

-

After Warranty Service:

-

Video technical support

-

Showroom Location:

-

Turkey

-

Marketing Type:

-

Hot Product 2019

Quick Details

-

Condition:

-

New

-

Plate Type:

-

Letterpress

-

Color & Page:

-

single color

-

Voltage:

-

380V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LC

-

Model Number:

-

H-TC50SA

-

Usage:

-

Cosmetic case, soft tube, Tube Printer

-

Weight:

-

1590 KG

-

Platen Size:

-

20*30cm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

white:

-

steel

-

After Warranty Service:

-

Video technical support

-

Showroom Location:

-

Turkey

-

Marketing Type:

-

Hot Product 2019

Samples show

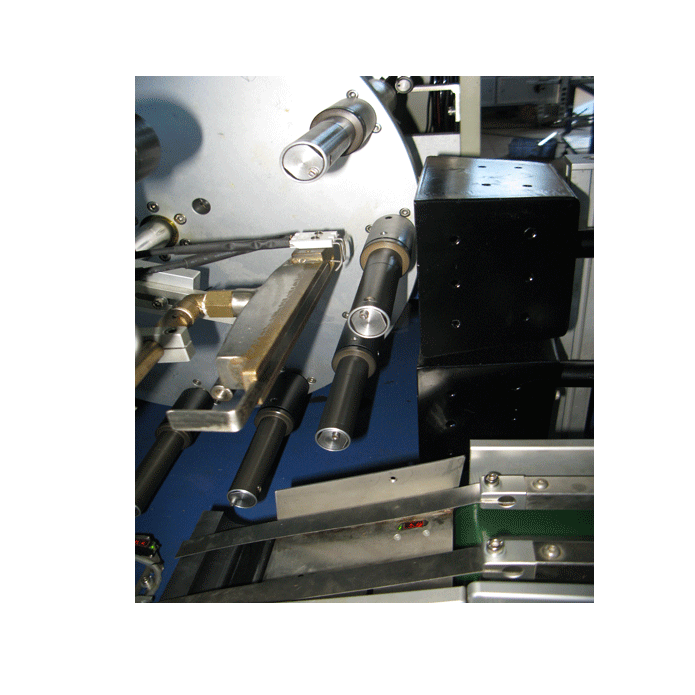

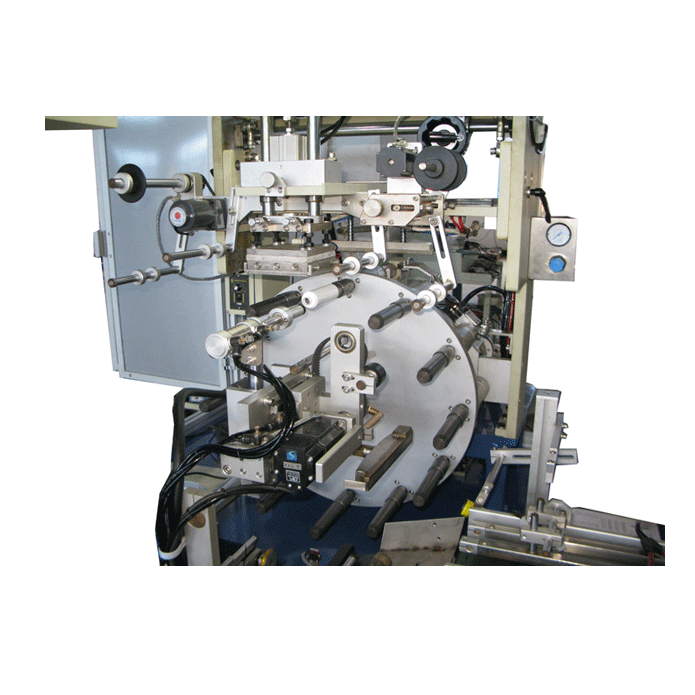

The automatic bronzing of cylindrical products is more common in the molten stamping machine using vertical turntable structure. It consists of an automatic feed mechanism, vertical turntable mechanism, positioning mechanism, automatic gold percent device, and automatic feeding mechanism. Complete processes such as transportation, hot bronze, and feeding, fast speed, good quality, widely used in industrial fields such as cosmetics, medicine, hoses, instruments, daily chemical products and other industrial fields.

The vertical turntable mechanism is a key component, material selection, processing technology, and processing accuracy of the macro -permeal permeability of the automotive permeability.

Machine description

|

H-TC50SA Full automatically Soft-tube hot stamping Machine // Structure |

|

|

Feeding |

Conveyor |

|

Initial position |

Sensor control |

|

Working table |

10 stations rotating disk, index plate control |

|

Surface treatment |

Flame treatment |

|

Press |

Vertical press |

|

Temperature control |

IR Heater, automatically controlling |

|

Foil collecting |

Automatically collecting |

|

Blanking |

Automatically |

|

H-TC50SA Full automatically Soft-tube hot stamping machine // Usage and characters |

|

|

Guide |

|

|

Application fields |

|

|

H-TC50SA Full automatically cap-side hot stamping Machine // Parameter |

|

|

Technical parameters |

|

|

Works supply |

|

|

Package list |

|

|

H.S.Code |

8443198000 |

|

Certificate |

CE |

|

H-TC50SA Full automatically Soft-tube hot stamping machine // Advantage |

|

|

Function |

|

Machine details

1. What is Hot foil stamping machine ?

The hot stamping machine is a special packaging and printing equipment that uses heat and pressure to transfer the metal coating on the foil film to the product. It is widely used in paper, plastic, leather, glass, wood and other products

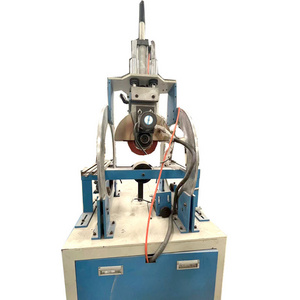

2 . Types of hot foil stamping machines.

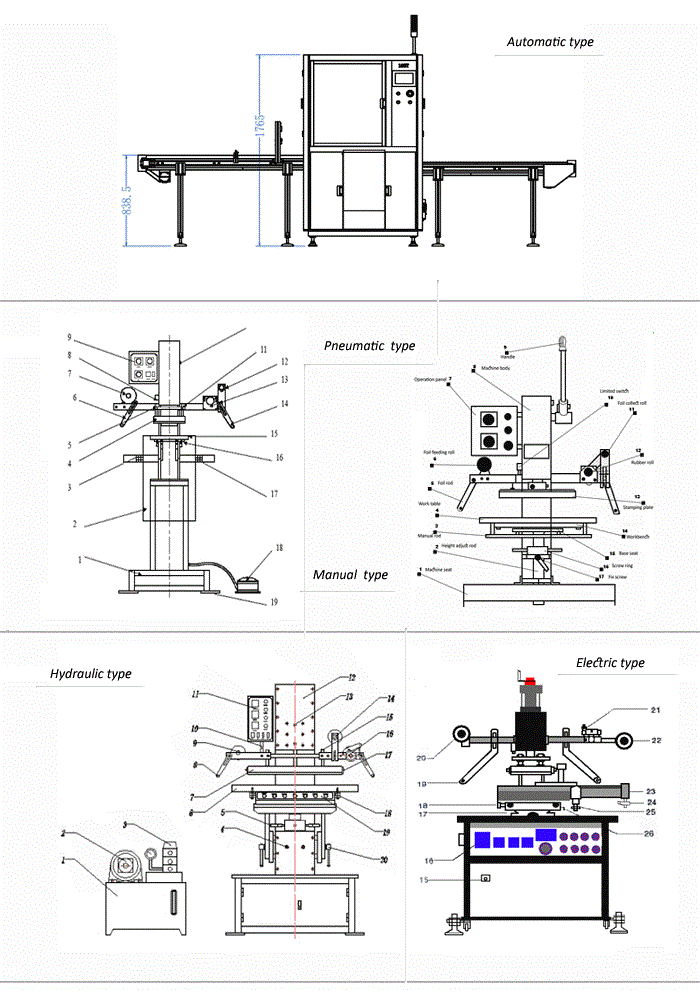

According to the power source of the hot stamping machine to generate pressure, it can be divided into manual hot stamping machine, pneumatic hot stamping machine, hydraulic hot stamping machine and electric hot stamping machine. According to the degree of automation of the hot stamping machine, it can be divided into: semi-automatic hot stamping machine and automatic hot stamping machine

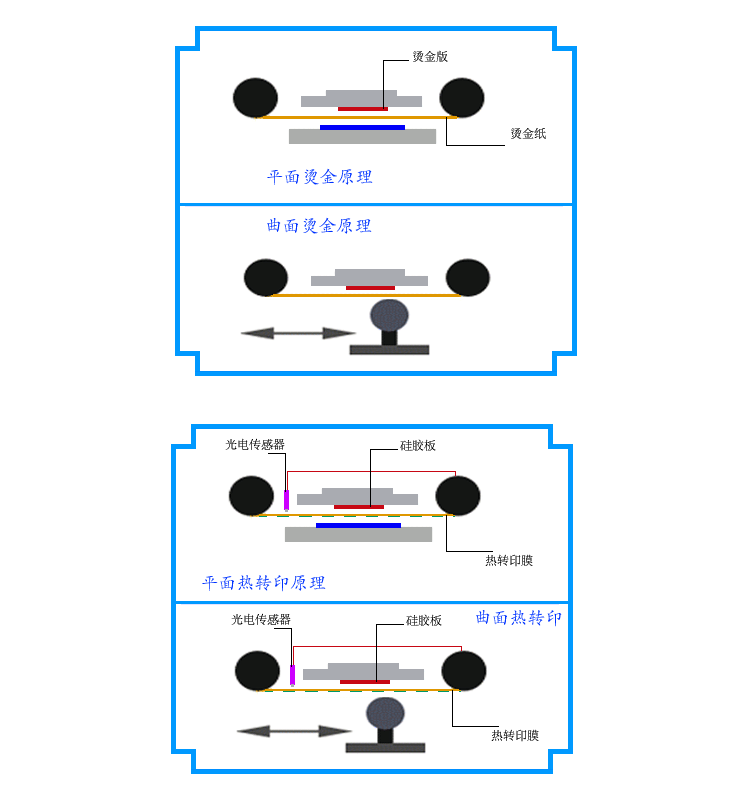

3. Foil stamping and heat transfer printing

Hot stamping and thermal transfer are closely related and difficult to distinguish on many occasions. Generally speaking, machines that use anodized aluminum can be called hot stamping machines, machines that use printed transfer films are called heat transfer machines, and machines that use heat transfer films are usually Photoelectric switches will also be installed to identify the pitch points of the thermal transfer printing film to achieve the positioning function! Some people also use whether the ironing head is a flat plate or a rubber roller to distinguish between a hot stamping machine and a heat transfer machine. Obviously, it is also difficult to distinguish them in terms of the applicability of anodized aluminum and heat transfer films!

4. Hot stamping machine operating system

The ordinary hot stamping machine adopts the microcomputer control system , the high-end hot stamping machine and automatic hot stamping machine uses the PLC to carry on the control, specially the servo control system hot stamping machine or the automatic hot foil stamping machine, uses the PLC control system quite commonly.

5. Hot stamping machine movement characteristics

The actions of the hot stamping machine mainly include the entry and exit and rotation of the worktable, the rotation of products and fixtures, the up and down and rotation actions of the ironing head, and the conveying and unloading actions of the products of the automatic hot stamping machine. Most of these actions are controlled by pneumatics, and a few are controlled by hydraulics. Those that require precise control are driven by motors or servo motors. As the market continues to improve the quality of hot stamping, various automatic hot stamping machines controlled by precision instruments have emerged!

6. How to evaluate the quality of the hot stamping machine?

Hot foil stamping machine technology content is low, more and more enterprises began to produce and sell hot stamping machines, hot stamping machines of uneven quality, how to evaluate the quality of hot stamping machine is essential. As the majority of brand-name hot stamping machine is not sold through the network, so, through Alibaba sales of hot stamping machines are low-end hot stamping machine.

1) Design of the factory means: a special design department of the enterprise quality is more reliable. China has 70% of the hot stamping machine manufacturing enterprises and no special design department, the development of new products on-site assembly by the basic, which is extremely adverse to the standardization of production machinery;

2) Processing means: CNC processing costs are higher, but the parts manufactured high precision; visit the factory must inspect whether the factory has CNC machining capacity;

3) Materials Selection: Material selection is very important. Now fierce competition, the vast majority of domestic factories in the selection of the above efforts, only the brand enterprises are willing to insist on the selection criteria above;

7. How to choose hot stamping die?

There are two main types of hot stamping plates, one is made by engraving copper plates, and the other is made by pressing silicone rubber. Copper plates are often used for printing substrates with softer materials, such as paper, leather, wood, and cloth; silicone plates are often used for printing substrates with relatively hard materials, such as glass, ceramics, plastics, and metals. For cold stamping processes, silicone rubber plates are also commonly used.