- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HOLSTEN

-

Dimension(L*W*H):

-

Customized

-

Capacity:

-

Customized

-

Weight:

-

3000

-

Inner Material:

-

Carbon steel / Stainless steel

-

Outer Material:

-

Cold rolled

-

Design Pressure(MPa):

-

0.5-5.0

-

Design Standard:

-

GB150/ASME

-

Working Temperature(℃):

-

100 - 450 ℃

-

Name:

-

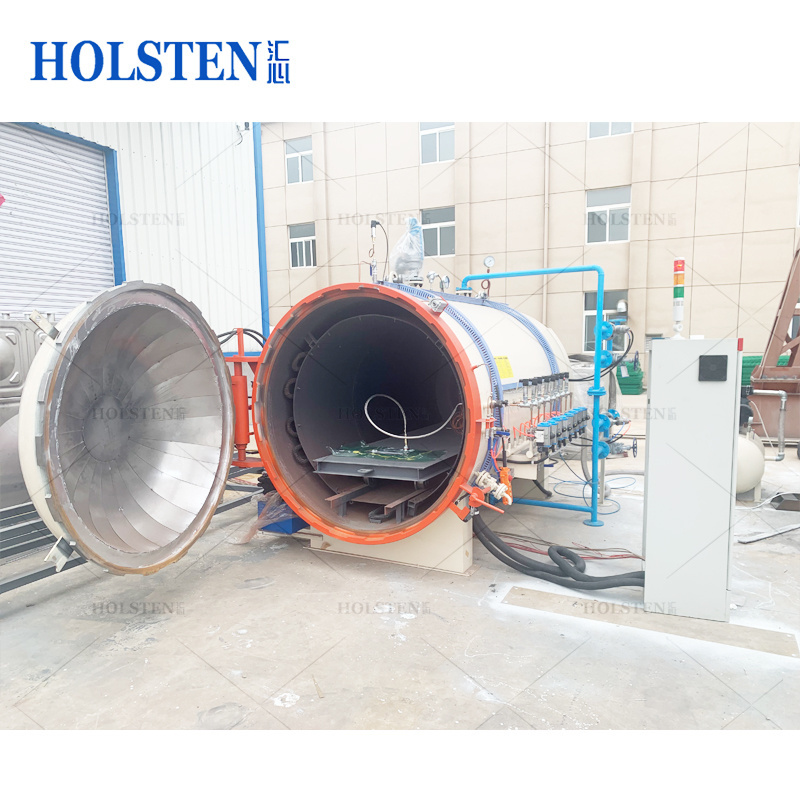

Autoclave for aerospace composite autoclave carbon fiber

-

Type:

-

Composite carbon fiber autoclave

-

Style:

-

Horizontal

-

Raw material:

-

Carbon steel / stainless steel

-

Function:

-

High temperature & high pressure

-

Application:

-

Composite carbon fiber material

-

Medium:

-

Hot air

-

Insulation:

-

Internal insulation / external insulation

-

Heating method:

-

Electric heating

-

Cooling method:

-

Water cooling / air cooling

Quick Details

-

Volume (m³):

-

0.1-50

-

Max Working Pressure(MPa):

-

4.8

-

Place of Origin:

-

SHN

-

Brand Name:

-

HOLSTEN

-

Dimension(L*W*H):

-

Customized

-

Capacity:

-

Customized

-

Weight:

-

3000

-

Inner Material:

-

Carbon steel / Stainless steel

-

Outer Material:

-

Cold rolled

-

Design Pressure(MPa):

-

0.5-5.0

-

Design Standard:

-

GB150/ASME

-

Working Temperature(℃):

-

100 - 450 ℃

-

Name:

-

Autoclave for aerospace composite autoclave carbon fiber

-

Type:

-

Composite carbon fiber autoclave

-

Style:

-

Horizontal

-

Raw material:

-

Carbon steel / stainless steel

-

Function:

-

High temperature & high pressure

-

Application:

-

Composite carbon fiber material

-

Medium:

-

Hot air

-

Insulation:

-

Internal insulation / external insulation

-

Heating method:

-

Electric heating

-

Cooling method:

-

Water cooling / air cooling

Autoclave for aerospace composite autoclave carbon fiber

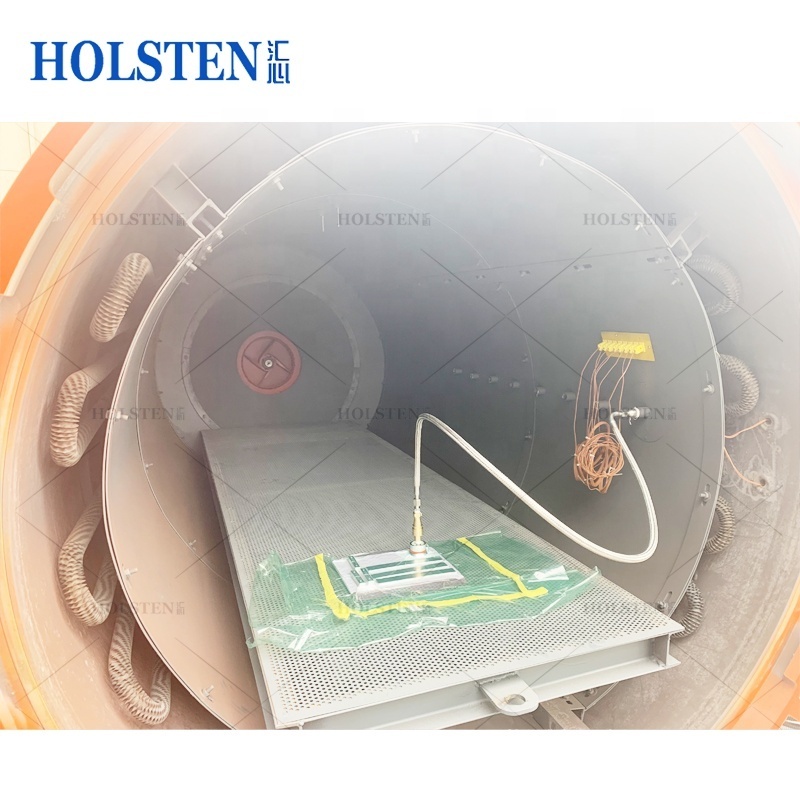

Brand and Material of Major Components

|

No. |

item |

material |

|

1 |

dished head |

carbon steel Q345R |

|

2 |

tank |

carbon steel Q345R |

|

3 |

flange |

forged carbon steel |

|

4 |

safety interlocking device (pressure automatic) |

|

|

5 |

track |

carbon or stainless steel |

|

6 |

manual door opening device |

|

|

7 |

saddle |

carbon steel Q235B |

|

8 |

High temperature and high pressure fan ventilator |

air or water cooling |

|

9 |

thermal insulation head |

carbon steel Q235B |

|

10 |

Insulation material (double layer) |

aluminum silicate cotton |

Sealing mode:

Inflatable silicone seal rings are used for tank door flanges which is simple and convenient to maintain and the sealing effect is obviously better than other methods with more than 2 years of service life.

Temperature control mode:

It uses double layer external insulation, saving thirty percent of energy consumption than ordinary insulation.

Time control mode:

After setting working procedure, heating/keep-heating time and vulcanization time all will be automatically controlled.

Pressure control mode:

(1) Pressure in vulcanization tank is automatically controlled by pneumatic corner valve.

(2) Set up manual valve for easy manual control.

(3) Set up another set of disc pressure gauge.

(4) The tank body is designed with two flanged open safety valves, which can be opened automatically after the designed pressure is reached.

Door opening mode:

1.Power-driven

2.Hand-driven

3.Hydrodynamic-driven

4.Various types of vulcanization tank and quick-opening door safety interlocking devices can be provided separately.(Company advantage)

Q: Are you manufacturer or trading company?

A: We are a professional manufacturer.

Q: What is your business scope?

A: There are categories such as vulcanization autoclave, composite autoclave , wood processing autoclave, etc.

Q: What if there is something wrong with the machine within one year?

A: We have two ways to solve the problem.

a. Phone call/on-line service to solve the problem.

b. We will take video to show ’how to solve the problem’. All the problems can be solved by video guidance.

Q: How about the installation? And what if the machine goes down?

A: We will do that. There are two options.

a. We could appoint our engineer to your company to install and debug, as for the cost of this trip such as ticket, visa, accommodation and labor cost shall be on your side.

b. On-line service will be provided. If still is under guarantee period, the necessary accessories and parts will be provided free, but the transportation cost of it shall be on your side.