- Product Details

- {{item.text}}

Quick Details

-

Use:

-

Warehouse Rack

-

Place of Origin:

-

Ho Chi Minh City, Vietnam

-

Brand Name:

-

Viet Mechanical

-

Model Number:

-

Warehouse Storage Powder Coating Steel Platform

-

Depth:

-

3-10 pallet

-

Weight Capacity:

-

500-2000kg

-

Width:

-

Customize

-

Height:

-

12m or Customized

-

Finish:

-

Hot Dip Gavanized; Powder Coating

-

Package:

-

Standard Exported Package

-

Payment Terms:

-

50% Deposit 50% Balanced

-

Warranty:

-

1000-4000kg

-

Color:

-

Customized Color

-

Delivery time:

-

30 days or more depending on quantity

-

Service:

-

Customer Designs

-

Certification:

-

CE

Quick Details

-

Type:

-

Drive-In Pallet Rack

-

Material:

-

G450, G550, SS400, SS490 High Class Carbon Steel

-

Feature:

-

Corrosion Protection

-

Use:

-

Warehouse Rack

-

Place of Origin:

-

Ho Chi Minh City, Vietnam

-

Brand Name:

-

Viet Mechanical

-

Model Number:

-

Warehouse Storage Powder Coating Steel Platform

-

Depth:

-

3-10 pallet

-

Weight Capacity:

-

500-2000kg

-

Width:

-

Customize

-

Height:

-

12m or Customized

-

Finish:

-

Hot Dip Gavanized; Powder Coating

-

Package:

-

Standard Exported Package

-

Payment Terms:

-

50% Deposit 50% Balanced

-

Warranty:

-

1000-4000kg

-

Color:

-

Customized Color

-

Delivery time:

-

30 days or more depending on quantity

-

Service:

-

Customer Designs

-

Certification:

-

CE

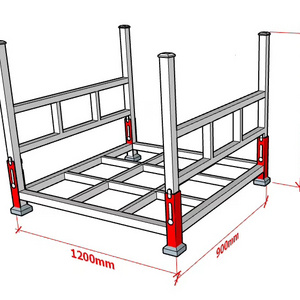

Specification

|

Item

|

Value

|

|

Product Name

|

Drive-in Racking system

|

|

Depth

|

3-10 pallet

|

|

Width

|

Customized

|

|

Material

|

G450, G550, SS400, SS490 High Class Carbon Steel

|

|

Package

|

Standard Exported Package

|

|

Payment Terms

|

50% Deposit 50% Balanced

|

|

Warranty

|

24 Months

|

|

Use

|

Warehouse Rack

|

|

Weight Capacity

|

500-2000kg

|

|

Height

|

12m or Customized

|

|

Delivery time

|

30 days or more depending on quantity

|

|

Service

|

Customer Designs

|

|

Finish

|

Hot Dip Gavanized; Powder Coating

|

|

Specification

|

Warehouse Storage Powder Coating Steel Platform

|

|

Certification

|

CE

|

Product Description

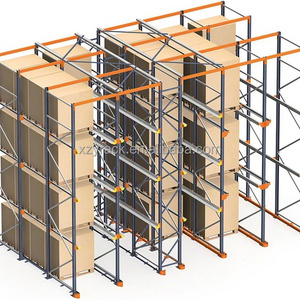

What is the drive in racks?

Drive in racking is a type of warehouse racking system used to store homogeneous goods, the same pallet, store goods in large quantities, optimize space and warehouse area for aisles. This is a racking system that offers outstanding storage capacity by making full use of warehouse space, fully meeting the needs of customers: durable, beautiful, solid, high investment efficiency.

- Goods are absolutely preserved to a height of 11m.

- Large volume of goods.

This racking system is usually built adjacent to each other in a mixed warehouse system. Drive rack design with structure with inlet or through channel. The pallets are stacked next to each other along the track, to go deep inside the trench system, which is moved by specialized vehicles such as Reach Truck, Forklift, and shelves.

Each rail of the Drive-in racking system has a capacity of 1-8 pallets or more, shelf height from 2-7 floors.

On the principle of importing and exporting goods in warehouse shelves:

-Drive Thru solution (FIFO – First In/First Out)

The standard import process is first in - first out

With this solution, one party imports the goods and the other places an order, which means that the goods that come in first, go out first. The "first in, first out" benefit is for products with a shelf life, e.g. perishables such as food, beverages, consumables with a short shelf life, products with a limited shelf life. short. Fashion has a low life cycle… with those items you'll definitely want to clear your inventory first. If those items are not shipped first, but you sell new goods, then you will definitely stock up on old and expired goods.

- Drive in solution (FILO - First-in/Last-Out)

The process of importing goods according to the standard First in - Last out

Designed to import and export goods from only one side, goods put in last take out first. Effective use for items with long-term use such as building materials, plastics, machinery, equipment and tools and wood furniture industry.

Advantages of Drive in racking system for warehouses

- Low investment costs compared to the throughput achieved.

- Optimizing cost on warehouse space compared to other storage shelves.

- Absolutely optimize space, warehouse area, make use of every m2 in the warehouse into a place to store goods.

- Convenience in the use of forklifts.

- Two solutions "FILO" and "FIFO" can be combined to increase efficiency.

- Storage of bulk goods

- The design is sturdy, durable, meets the standards of load and safety.

Hot Searches