- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

STA

-

Alumina:

-

95%-99%

-

Color:

-

White

-

High Temperature Resistance:

-

1800C

-

Voltage resistance:

-

16-25V

-

Density:

-

3.96g/cm3

-

OEM:

-

Available

-

Certificate of Origin:

-

CO,Form-E,Form-F

Quick Details

-

Material:

-

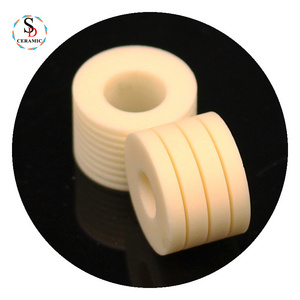

Alumina Ceramic

-

Place of Origin:

-

Henan, China

-

Model Number:

-

Customer's Requirements

-

Brand Name:

-

STA

-

Alumina:

-

95%-99%

-

Color:

-

White

-

High Temperature Resistance:

-

1800C

-

Voltage resistance:

-

16-25V

-

Density:

-

3.96g/cm3

-

OEM:

-

Available

-

Certificate of Origin:

-

CO,Form-E,Form-F

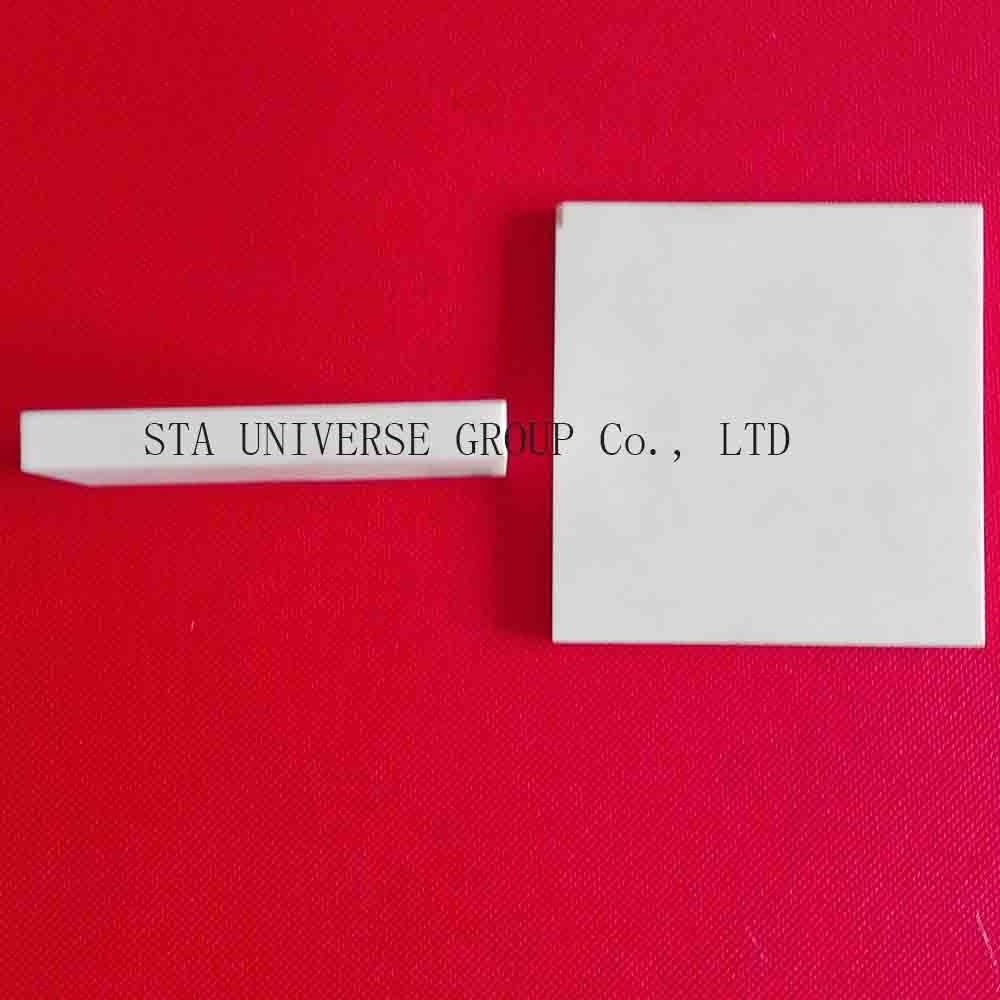

STA Advanced Industrial Ceramics 96% 99% Alumina Plate / Al2O3 Ceramic Plate

Brief Introduction

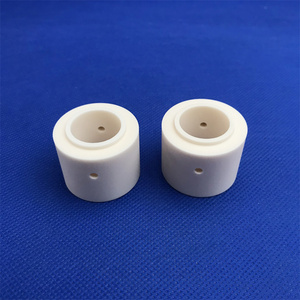

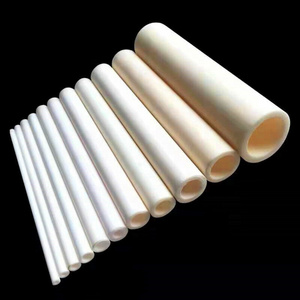

Aluminum Oxide Ceramic is wildely used in many fields including mechanical, electronics, electrical, semiconductor, automotive, textile, etc. For the good propertities, more and more customers choose Alumina ceramic materials for their applications. Alumina Ceramic can be made to Ceramic Nozzles, Ceramic Sprayers Cyclones, Ceramic Linings, Milling Systems, Ceramic Thread guides, etc. Customized designs are very often to be made.

- Great Hardness

Have a Rockwell hardness of up to 90 which is well above that of wear-resistant steel and stainless steel.

- Excellent wear resistance

Its wear-resistance is equivalent to 266 times that of manganese steel and 171.5 times that of high chromium cast iron. Under the same working conditions, the service life of pipes lined with high alumina ceramics can be prolonged at least 10 times.

- Corrosion resistance

Its extremely high stability of molecular structure ensures its resistance to corrosion from various acid and alkali mediums.

- Light weight

Its density is 3.6 g/cm3, only half of steel, making installation more convenient.

Technical dates of the alumina ceramic plate

| Description/Size | Length(mm) | Width(mm) | Thickness(mm) |

| 50 × 25 | 50 | 25 | 5-12 |

| 50 × 50 | 50 | 50 | 5-20 |

| 100 × 100 | 100 | 100 | 6-15 |

| 120 × 80 | 120 | 80 | 6-20 |

| 150 × 60 | 150 | 60 | 10-25 |

| 150 × 100 | 150 | 100 | 6-50 |

| 230 × 114 | 230 | 114 | 50-65 |

| 100 × 25 | 100 | 25 | 5-15 |

| 100 × 50 | 100 | 50 | 5-20 |

| 100 × 75 | 100 | 75 | 12-25 |

| 114 × 114 | 114 | 114 | 12-25 |

| 120 × 80 | 120 | 80 | 10-25 |

| 150 × 25 | 150 | 25 | 5-15 |

| 150 × 50 | 150 | 50 | 3-20 |

| 228 × 114 | 228 | 114 | 12-50 |

| 70 × 70 | 70 | 70 | 10-25 |