- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Processing:

-

Brick production line

-

Place of Origin:

-

China

-

Brand Name:

-

QT

-

Voltage:

-

380 V

-

Dimension(L*W*H):

-

8000x4700x2400mm

-

Weight (KG):

-

100000 kg

-

Name:

-

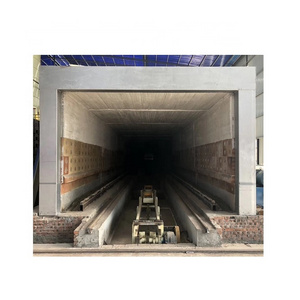

YZM 4.6m assembled tunnel kiln

-

the range of the material:

-

clay, shale, coal gangue, slag

-

structure:

-

Steel frame with mullite and refractory cotton

-

the characteristics:

-

high yield and easy installation

-

advantages:

-

Modular factory production

-

fuel:

-

Natural gas, coal, etc

-

Brick type:

-

Hollow brick, solid brick

-

After Warranty Service:

-

Video technical support

Quick Details

-

Type:

-

Hollow Block Making Machine, Interlock Block Making Machine, Hollow brick and solid brick production line

-

Brick Raw Material:

-

clay,Coal gangue, shale, slag

-

Production Capacity (Pieces/8 hours):

-

90000-110000 pce/24hours

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Processing:

-

Brick production line

-

Place of Origin:

-

China

-

Brand Name:

-

QT

-

Voltage:

-

380 V

-

Dimension(L*W*H):

-

8000x4700x2400mm

-

Weight (KG):

-

100000 kg

-

Name:

-

YZM 4.6m assembled tunnel kiln

-

the range of the material:

-

clay, shale, coal gangue, slag

-

structure:

-

Steel frame with mullite and refractory cotton

-

the characteristics:

-

high yield and easy installation

-

advantages:

-

Modular factory production

-

fuel:

-

Natural gas, coal, etc

-

Brick type:

-

Hollow brick, solid brick

-

After Warranty Service:

-

Video technical support

Product Description

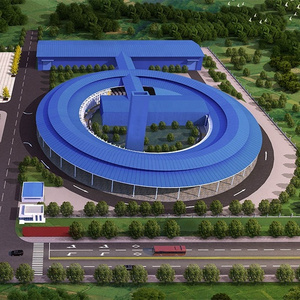

YZM series assembled tunnel kilns

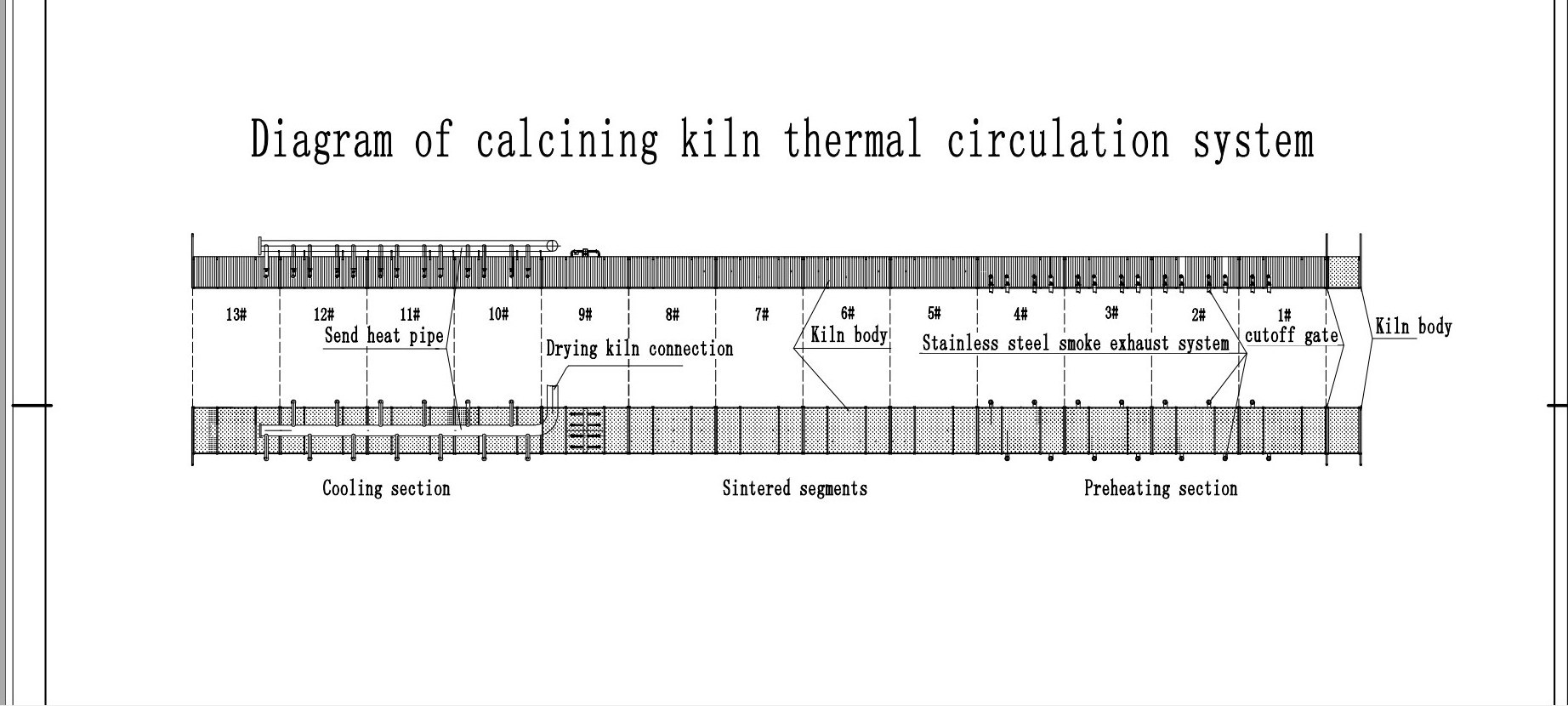

YZM series energy-saving assembled tunnel kiln

is divided into preheating section, high temperature section and cooling section. The three parts work independently and cooperate with each other.The flue gas in the preheating section is pumped into the flue gas purification system by the centrifugal fan, and then discharged.In the roasting stage, gas, liquid and solid fuel can be used to fire the bricks, and the waste heat extracted from the cooling stage is sent to the drying kiln through the pipeline to dry the bricks. It is energy saving and environmental protection, with high heat use efficiency. At the same time, it can also increase the water tank to provide domestic hot water for the brick factory.

YZM series energy-saving assembled tunnel kiln

is the operation and temperature control to achieve the cleavage management technology, so that the production efficiency and product quality greatly improved, safe and reliable, simple operation, easy temperature control.

Factory production, site assembly, construction period is short, the foundation is completed within one month after the assembly and firing kiln.

Factory production, site assembly, construction period is short, the foundation is completed within one month after the assembly and firing kiln.

The assembled tunnel kiln has high cost performance, no drying kiln can be directly ignited, the whole body can be removed and transferred, recycling and reuse.

Specification

|

Name

|

Kiln width

|

Kiln Height

|

Product categories

|

Production capacity

|

Average heat loss

|

|

YZM350

|

3.5M

|

|

Solid brick,

hollow brick

|

80000-100000

pcs/day

|

|

|

YZM460

|

4.6M

|

|

130000-160000

pcs/day

|

|

|

|

YZM550

|

5.5M

|

|

260000-300000

pcs/day

|

|

|

|

YZM730

|

7.3M

|

|

330000-360000

pcs/day

|

|

|

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches