- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

500

-

Product name:

-

DZ brand top sale aluminum truck wheel rim polishing machine

-

Model:

-

DZP-700/DZP-800/DZP-900

-

MOQ:

-

1 Set

-

Volume:

-

100-900L

-

Wheel Diameter:

-

Differ

-

Suitable material:

-

carbon steel and polyurethane

-

Usage:

-

Polishing Surface

-

Accessories:

-

Polishing wheel rim hub

-

Application:

-

Polishing

-

Certificate:

-

CE ISO BV SGS

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DZJX

-

Power (kW):

-

1.37

-

Weight (KG):

-

500

-

Product name:

-

DZ brand top sale aluminum truck wheel rim polishing machine

-

Model:

-

DZP-700/DZP-800/DZP-900

-

MOQ:

-

1 Set

-

Volume:

-

100-900L

-

Wheel Diameter:

-

Differ

-

Suitable material:

-

carbon steel and polyurethane

-

Usage:

-

Polishing Surface

-

Accessories:

-

Polishing wheel rim hub

-

Application:

-

Polishing

-

Certificate:

-

CE ISO BV SGS

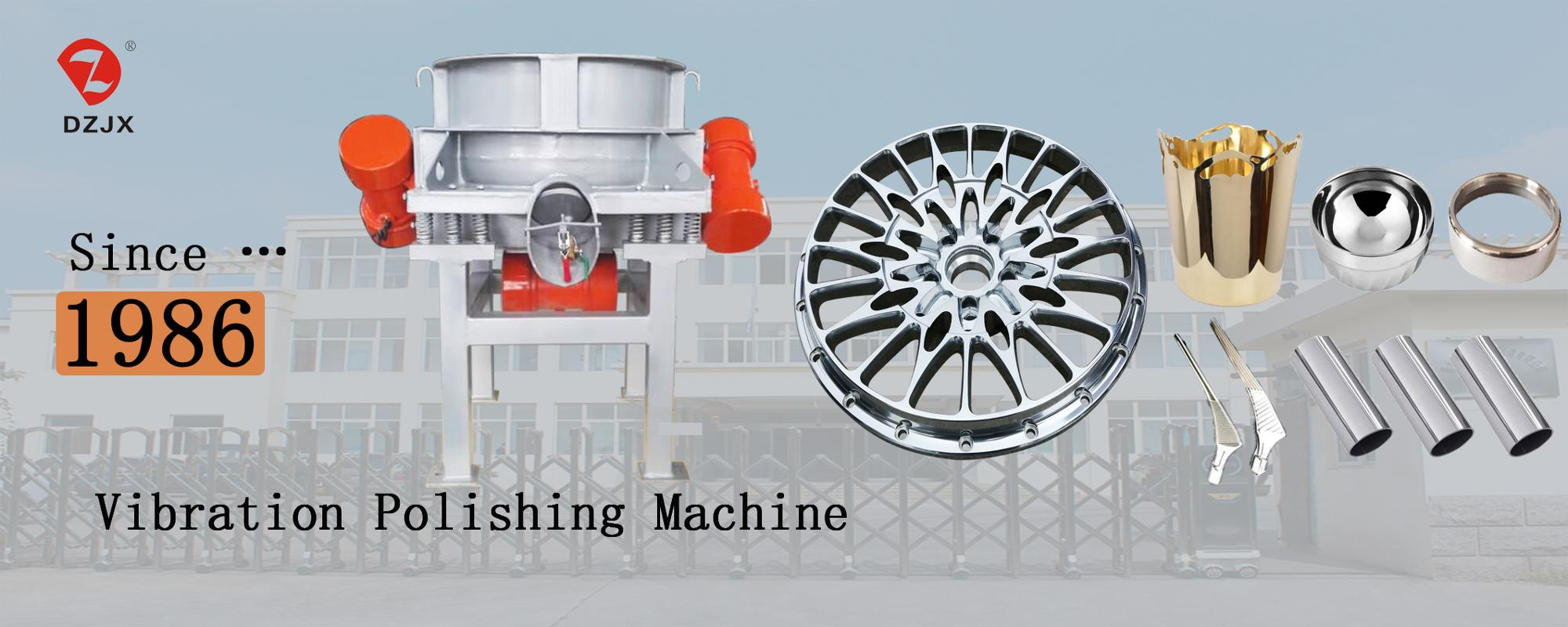

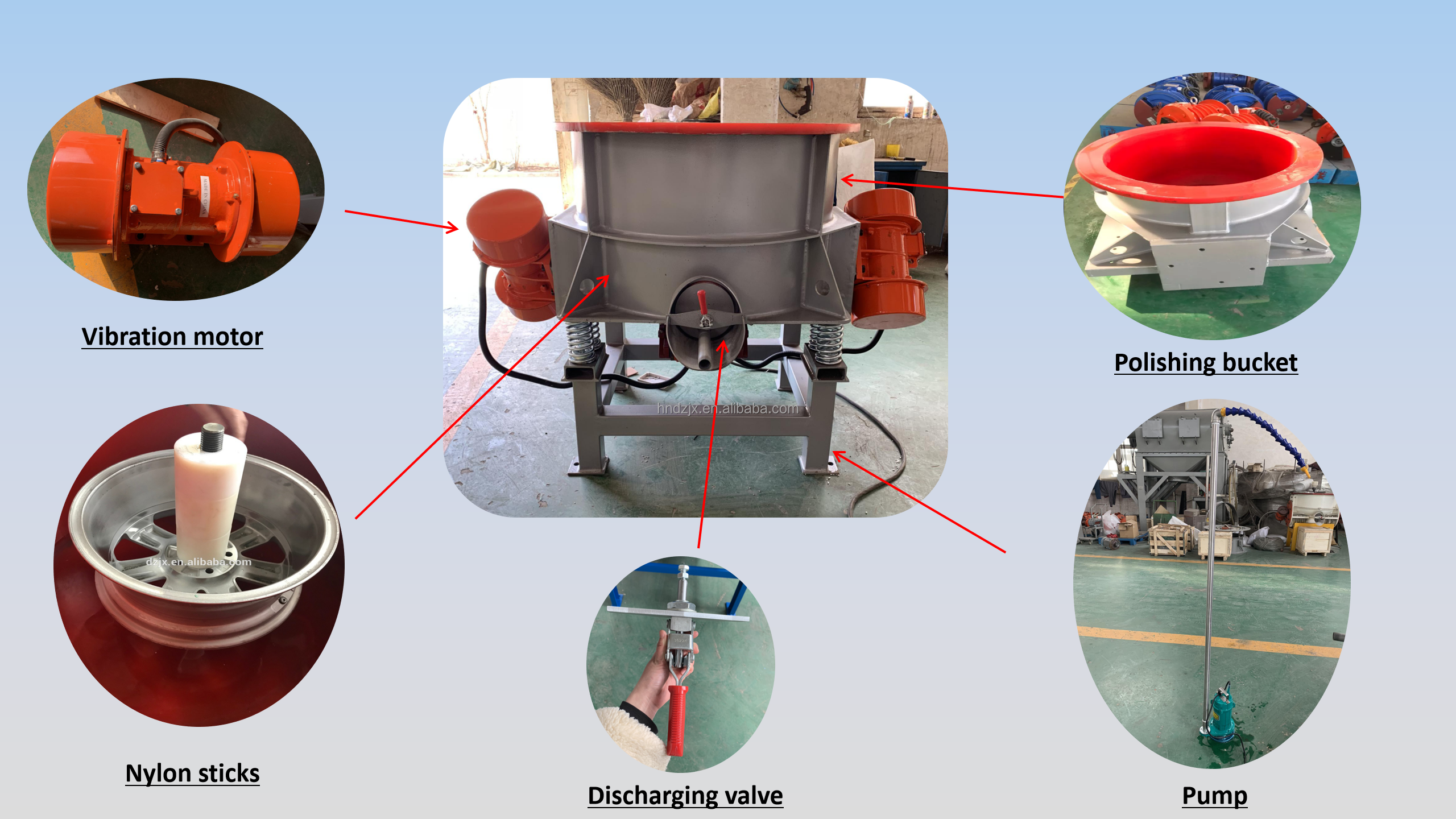

Product Description

DZJX Series Vibration Polishing Machine has a ring chamber to hold media (abrasive stones) and work pieces.When the machine start working,it makes three-D high frequency vibration.This motion makes the media work on surface of work pieces upward &downward, leftward and rightward, frontward and backward,t

hus achieving the purpose of polishing and cleaning

.The process is similar to handwork of surface polishing.

To replace the traditional cloth-wheel polishing, the vibration polishing machine for metal working can save a lot of spending on manpower, and lower the cost of production.

Polishing steps

This vibrating polishing machine has

two steps

to deal with wheel.

The first step is to remove burrs, surface treatment. The materials used are resin and grinding liquid.

The second step is to enhance the brightness of the surface. The material is zirconia and polishing liquid.

The first step is to remove burrs, surface treatment. The materials used are resin and grinding liquid.

The second step is to enhance the brightness of the surface. The material is zirconia and polishing liquid.

Application

* Polishing wheel rims

* Polishing craft parts

* Polishing hardware parts

* Polishing craft parts

* Polishing hardware parts

Technical Parameters

|

Model

|

Effective Diameter

|

Bucket Height

|

Bucket Volume

|

Motor Power

|

|

DZP-700

|

660mm

|

350mm

|

120L

|

0.55*3KW

|

|

DZP-800

|

760mm

|

350mm

|

160L

|

1.9KW

|

|

DZP-900

|

860mm

|

500mm

|

280L

|

2.1KW

|

Detailed image

Using Effects

Packing & Delivery

FAQ

Q:What factors I need to get a quotation?

A: Maximum wheel rim size;voltage and frequency (Hz)

Q:What is the real delivery time of your factory?

A: 7 to 15 days for general series products, meanwhile, batches products & customized products would need 30 days to 60 days based

on different situations.

Q: How do your after-sale service work if the product got damaged?

A: In the guarantee time 12 months, our general after-sale service is changing the damaged parts for the customer, but if the damage could be repaired by slight cost, we would wait for the customer's bill for the fix cost and refund this part of cost.(Note: Vulnerable parts do not include.)

A: Maximum wheel rim size;voltage and frequency (Hz)

Q:What is the real delivery time of your factory?

A: 7 to 15 days for general series products, meanwhile, batches products & customized products would need 30 days to 60 days based

on different situations.

Q: How do your after-sale service work if the product got damaged?

A: In the guarantee time 12 months, our general after-sale service is changing the damaged parts for the customer, but if the damage could be repaired by slight cost, we would wait for the customer's bill for the fix cost and refund this part of cost.(Note: Vulnerable parts do not include.)

Company Introduction

Feedback

Hot Searches