- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

600 KG

-

Place of Origin:

-

China

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2250*800*1700mm

-

Power (kW):

-

3 kW

-

Product name:

-

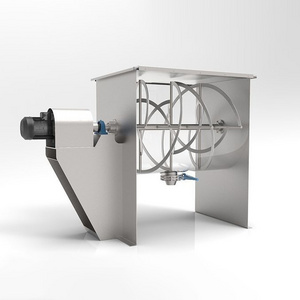

Dry powder mixer

Quick Details

-

Barrel Volume (L):

-

500

-

Max. Loading Volume (L):

-

500 L

-

Max. Loading Capacity:

-

2000L

-

Weight (KG):

-

600 KG

-

Place of Origin:

-

China

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2250*800*1700mm

-

Power (kW):

-

3 kW

-

Product name:

-

Dry powder mixer

Product Description

There are several advantages of using a dry powder mixer:

Efficient Mixing: Dry powder mixers are designed to provide efficient and thorough mixing of powdered ingredients. They use various mechanisms such as tumbling, blending, or agitating to ensure uniform distribution of particles and achieve a homogeneous mixture.

Time-saving: Dry powder mixers can significantly reduce the mixing time compared to manual mixing methods. They are equipped with powerful motors and mixing blades that can quickly blend the ingredients, saving both time and labor.

Consistency: Dry powder mixers ensure consistent mixing results, which is crucial in industries where product quality and uniformity are essential. By maintaining a consistent mixing process, these mixers help achieve reliable and repeatable outcomes.

Versatility: Dry powder mixers are versatile and can handle a wide range of powdered ingredients, including food additives, chemicals, and more. They can accommodate different batch sizes and offer adjustable mixing parameters to meet specific requirements.

Hygiene and Safety: Many dry powder mixers are designed with hygiene and safety in mind. They often feature easy-to-clean surfaces, removable parts, and safety interlocks to prevent accidents. This makes them suitable for industries with strict cleanliness and safety standards, such as food and pharmaceutical manufacturing.

Cost-effective: Dry powder mixers can help reduce production costs by minimizing ingredient waste and improving overall efficiency. They ensure thorough mixing, preventing the need for rework or product rejection due to inconsistent mixing.

Overall, dry powder mixers offer numerous advantages, including efficient mixing, time-saving capabilities, consistency, versatility, hygiene, safety, and cost-effectiveness. These benefits make them a valuable tool in various industries that deal with powdered ingredients.

Specification

|

item

|

value

|

|

Mixer Type

|

Agitator

|

|

Barrel Volume (L)

|

500

|

|

Material Processed

|

Plastics, Chemicals, Food

|

|

Max. Loading Volume (L)

|

500L

|

|

Max. Loading Capacity

|

2000L

|

|

Weight (KG)

|

600KG

|

|

Material

|

SUS304, SUS304L, SUS316, SUS316L, Ti

|

|

Condition

|

New

|

|

Product Type

|

Various dry powders

|

|

Application

|

Powder

|

|

Place of Origin

|

China

|

|

Voltage

|

380V

|

|

Dimension(L*W*H)

|

2250*800*1700mm

|

|

Power (kW)

|

3kW

|

|

Warranty

|

1 Year

|

|

Key Selling Points

|

Automatic

|

|

Applicable Industries

|

Manufacturing Plant, Food & Beverage Factory, Farms, Industrial mixing

|

|

Showroom Location

|

None

|

|

Marketing Type

|

New Product 2020

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Warranty of core components

|

1 Year

|

|

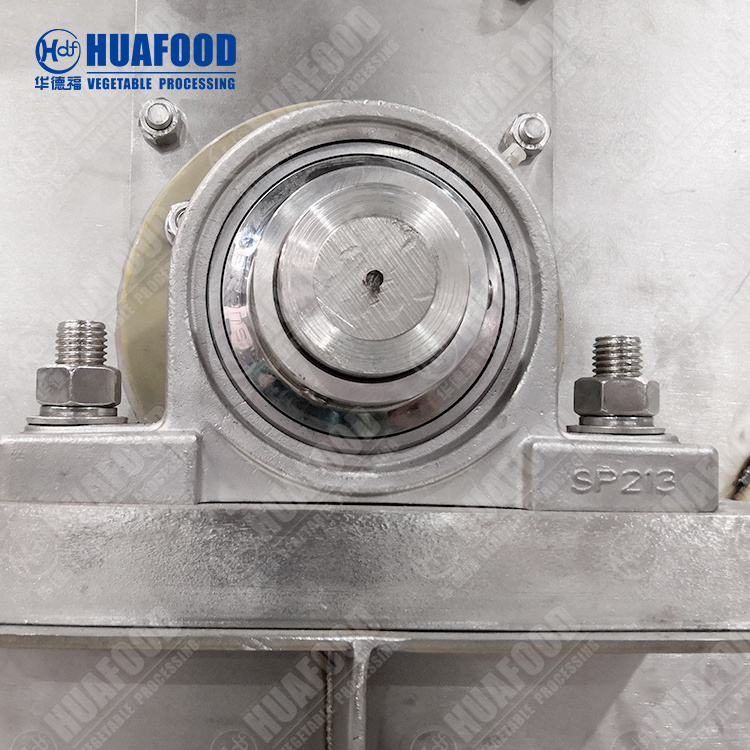

Core Components

|

Motor, Gear, Gearbox

|

|

Product name

|

Dry powder mixer

|

Packing & Delivery

Hot Searches