- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Y) (mm):

-

550

-

Dimension(L*W*H):

-

2650x2250x2650mm

-

Weight (T):

-

6.5 T

-

Positioning Accuracy (mm):

-

0.008

-

Repeatability (X/Y/Z) (mm):

-

0.004

-

Range of Spindle Speed(r.p.m):

-

0 - 8000 r.p.m

-

Spindle Motor Power(kW):

-

15/22.5

-

Max. Table Load(kg):

-

500 kg

-

Feed Speed(mm/min):

-

1 - 16000 mm/min

-

Rapid Feed Speed(m/min):

-

36/36/36

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

WMTCNC

-

Marketing Type:

-

New Product 2024

-

CNC or Not:

-

CNC

-

Product Type:

-

High Speed Vertical Machining Center CNC

-

Machine Name:

-

Heavy Duty Mineral Casting Vertical Machining Center

-

Keywords:

-

High Precision Vertical Machining

-

Precision:

-

High Precision High Accuracy for Sale

-

Function:

-

Metalworking

-

Voltage:

-

Customized Option

-

After-sales Service Provided:

-

Video Technical Support

-

Package:

-

Plywood Case

-

Video Outgoing-inspection:

-

Provided

Quick Details

-

Table Size (mm):

-

1200x550

-

Number of Axes:

-

3, 4, 5

-

Table Travel (X) (mm):

-

800

-

Table Travel (Y) (mm):

-

550

-

Dimension(L*W*H):

-

2650x2250x2650mm

-

Weight (T):

-

6.5 T

-

Positioning Accuracy (mm):

-

0.008

-

Repeatability (X/Y/Z) (mm):

-

0.004

-

Range of Spindle Speed(r.p.m):

-

0 - 8000 r.p.m

-

Spindle Motor Power(kW):

-

15/22.5

-

Max. Table Load(kg):

-

500 kg

-

Feed Speed(mm/min):

-

1 - 16000 mm/min

-

Rapid Feed Speed(m/min):

-

36/36/36

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

WMTCNC

-

Marketing Type:

-

New Product 2024

-

CNC or Not:

-

CNC

-

Product Type:

-

High Speed Vertical Machining Center CNC

-

Machine Name:

-

Heavy Duty Mineral Casting Vertical Machining Center

-

Keywords:

-

High Precision Vertical Machining

-

Precision:

-

High Precision High Accuracy for Sale

-

Function:

-

Metalworking

-

Voltage:

-

Customized Option

-

After-sales Service Provided:

-

Video Technical Support

-

Package:

-

Plywood Case

-

Video Outgoing-inspection:

-

Provided

Products Description

Main Features:

1.The spindle group is assembled with imported bearings and equipped with a constant temperature cooling system for the spindle.The Z-axis adopts the design of no counterweight, with the function of automatic motor holding brake, which provides more perfect 3D machining performance for machining.

2. X/Y/Z axis adopts line rail design and C3 grade high precision ball screw. Linear rail precision grade P.

3. The high flow rate flushing system in the chassis flushes the chips to the rear chip conveyor, which is convenient and easy to clean. Chain plate type chip conveyor lifting system and chip collecting trolley are optional.

|

Specification

|

ECO 800

|

|

X/Y/Z axis travel

|

800×550×550mm

|

|

Distance from spindle center to column

|

590mm

|

|

Distance from spindle nose to workable surface

|

120/170mm

|

|

Mesa form

|

T-slot 18×5

|

|

Worktable size(L×W)

|

1200×550mm

|

|

Max.loading of worktable

|

500kg

|

|

Spindle taper

|

BT40

|

|

Spindle speed

|

8000rpm

|

|

Power transmission mode

|

Synchronous belt type

|

|

Main motor power(V/H)

|

15/22.5kw

|

|

Rapid feed speed(X/Y/Z)

|

36/36/36 m/min

|

|

Cutting feed

|

1-16000mm/min

|

|

Minimum input unit

|

0.001mm

|

|

Tool number

|

24T

|

|

Tool selection method

|

Bothway

|

|

Tool change time

|

1.5s

|

|

Maximum diameter of adjacent tool

|

80mm

|

|

Tool length

|

300mm

|

|

Tool weight

|

8kg

|

|

Guideway type

|

Roller line rail

|

|

Overall positioning accuracy

|

0.008mm

|

|

Repositioning accuracy(X/Y/Z)

|

0.004mm

|

|

Cutting fluid tank

|

180L

|

|

Lubrication system

|

3L

|

|

Nc system brand

|

Windwin21s

|

|

Barometric demand

|

0.55-0.65mpa

|

|

power capacity

|

25kva

|

|

Machine weight

|

6500kg

|

|

Floor space

|

2650×2250×2650mm

|

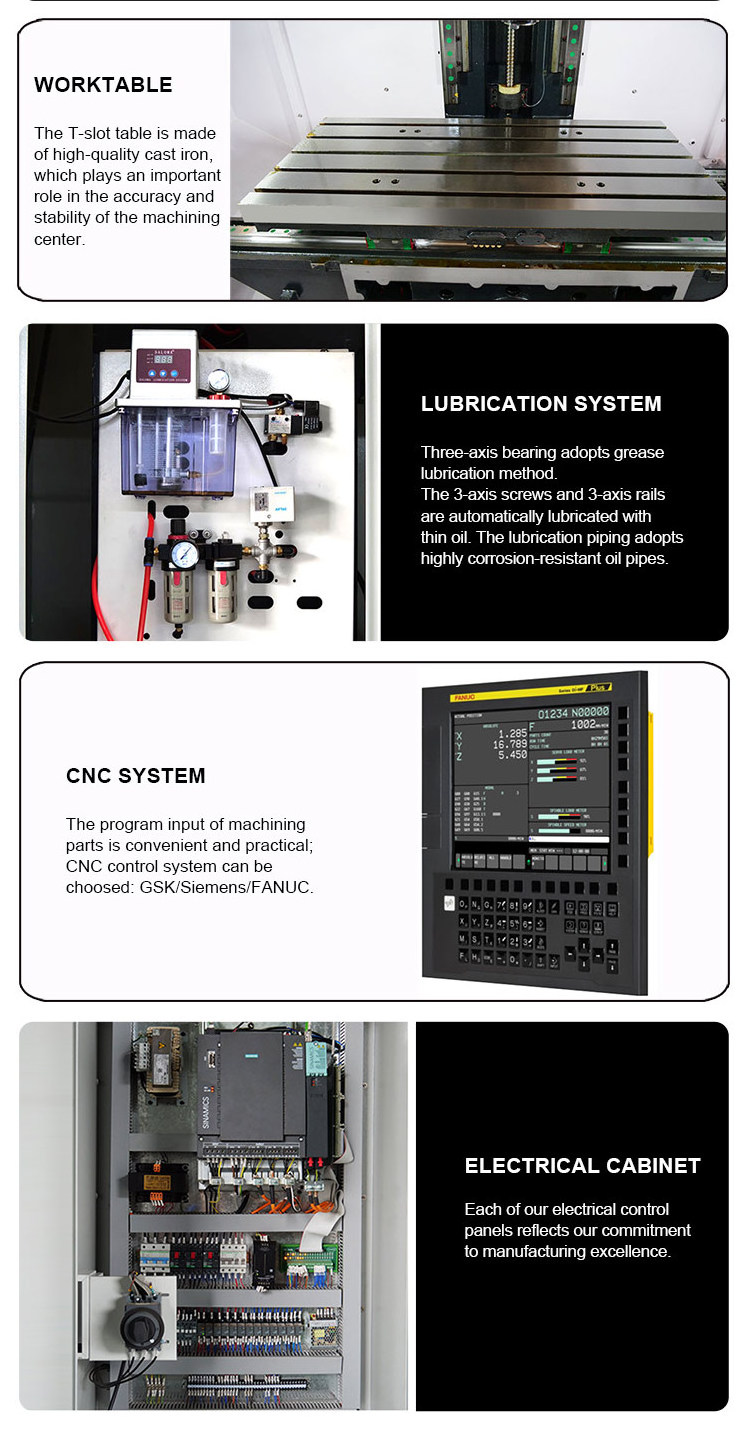

Detailed Images

Hot Searches