- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

5000L

-

Weight (KG):

-

2000 KG

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

BLS

-

Voltage:

-

110-480V, 50/60Hz

-

Dimension(L*W*H):

-

Custom Made

-

Power (kW):

-

7.5 kW

-

Warranty of core components:

-

0.5 years

-

Appliaction:

-

spice powder ribbon mixer

-

Type:

-

ribbon blender

-

Capacity:

-

100-5000L

-

Surface:

-

mirror polished

-

Pressure:

-

normal pressure

-

Motor:

-

horizontal motor

-

Outlet:

-

sanitary butterfly valve

-

Name:

-

Industrial blender machine/Spice powder ribbon mixer

-

Function:

-

Commercial blender/Spice powder ribbon mixer

Quick Details

-

Barrel Volume (L):

-

5000 L

-

Max. Loading Volume (L):

-

5000 L

-

Range of Spindle Speed(r.p.m):

-

20 - 25 r.p.m

-

Max. Loading Capacity:

-

5000L

-

Weight (KG):

-

2000 KG

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

BLS

-

Voltage:

-

110-480V, 50/60Hz

-

Dimension(L*W*H):

-

Custom Made

-

Power (kW):

-

7.5 kW

-

Warranty of core components:

-

0.5 years

-

Appliaction:

-

spice powder ribbon mixer

-

Type:

-

ribbon blender

-

Capacity:

-

100-5000L

-

Surface:

-

mirror polished

-

Pressure:

-

normal pressure

-

Motor:

-

horizontal motor

-

Outlet:

-

sanitary butterfly valve

-

Name:

-

Industrial blender machine/Spice powder ribbon mixer

-

Function:

-

Commercial blender/Spice powder ribbon mixer

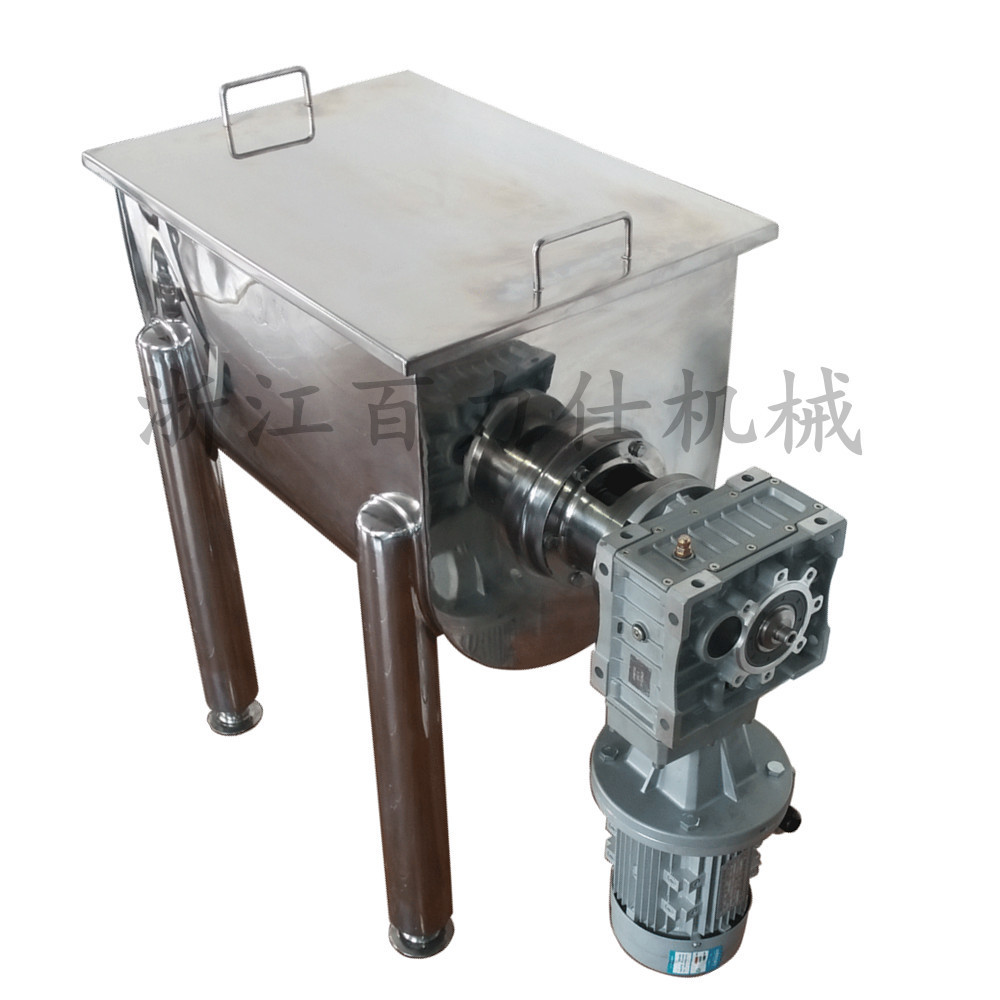

Quality stainless steel

Contact parts of machine are completely made of food grade stainless steel 304/316L, meeting the standard of GMP.

Motor device

Pure copper motor: low noise, stable dynamic, sustainable work.

SUS control panel avaible

SUS304 box, with switch to control turn on/turn off and emergency stop etc.

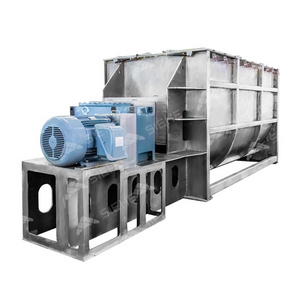

Stirring device

1. adopt double layer ribbon mixer

2. can be customized according to feeding materials

3. make feeding material fully stirred

Handle on flat top cover

Creative handle, quick to open, convenient for production

Full steel base adjustable feet(wheels avaible)

Can withstand greater pressure, stable work

Zhejiang L&B Fluid Equipment co., Ltd

a modern enterprise which combine the ability of design, development, manufacturing, engineering, installation, technical services, has special technology to design and exploit by CAD software and computer and is a outstanding leader among valve fields.

We have advanced CNC lathes imported from Japan.We can manufacture the valves and fitting according to ISO, DIN, IDF, SMS, 3A, while we can produce the products per as the requirement from the clients(non-standard).

We are specialized in producing different kinds of valves, pipe fitting, tubes, manhole covers, pumps, tanks etc for many years. We can design the products according to your special request. OEM is welcome too.