- Product Details

- {{item.text}}

Quick Details

-

Structure:

-

Safety

-

Warranty:

-

2 years

-

Place of Origin:

-

Shandong, China, Shandong

-

Brand Name:

-

LANGO

-

Model Number:

-

BYF

-

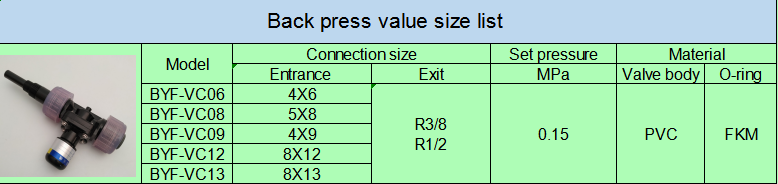

Port Size:

-

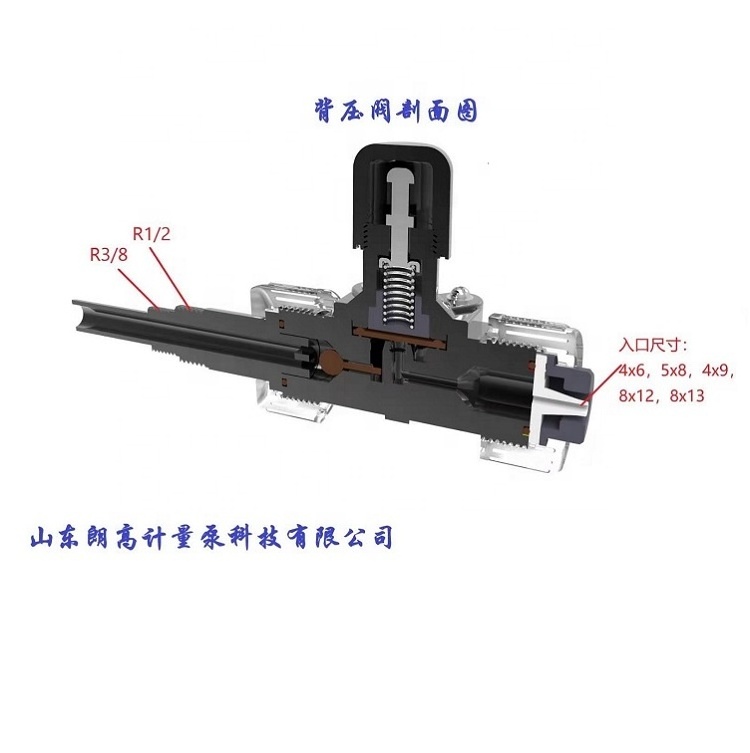

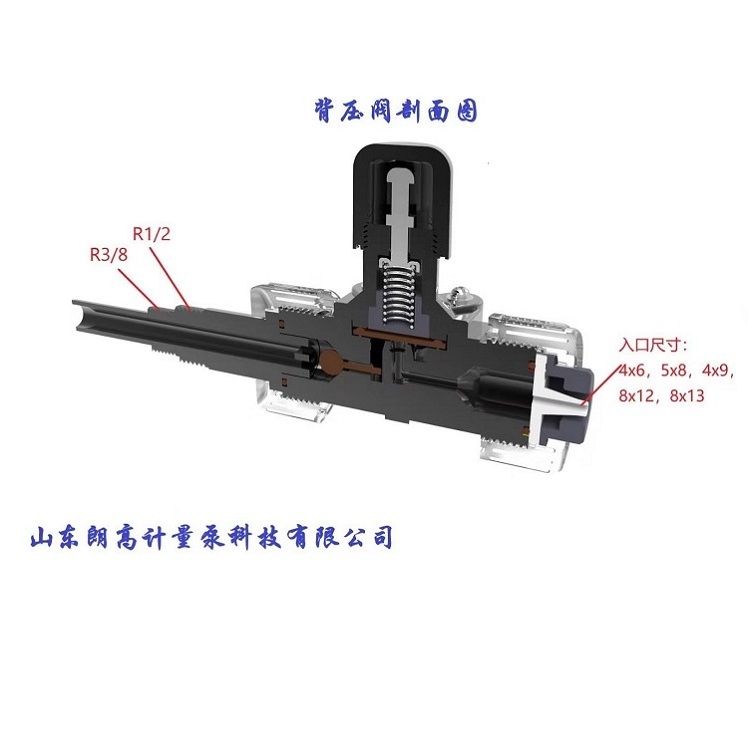

R1/2 R3/8

-

Product name:

-

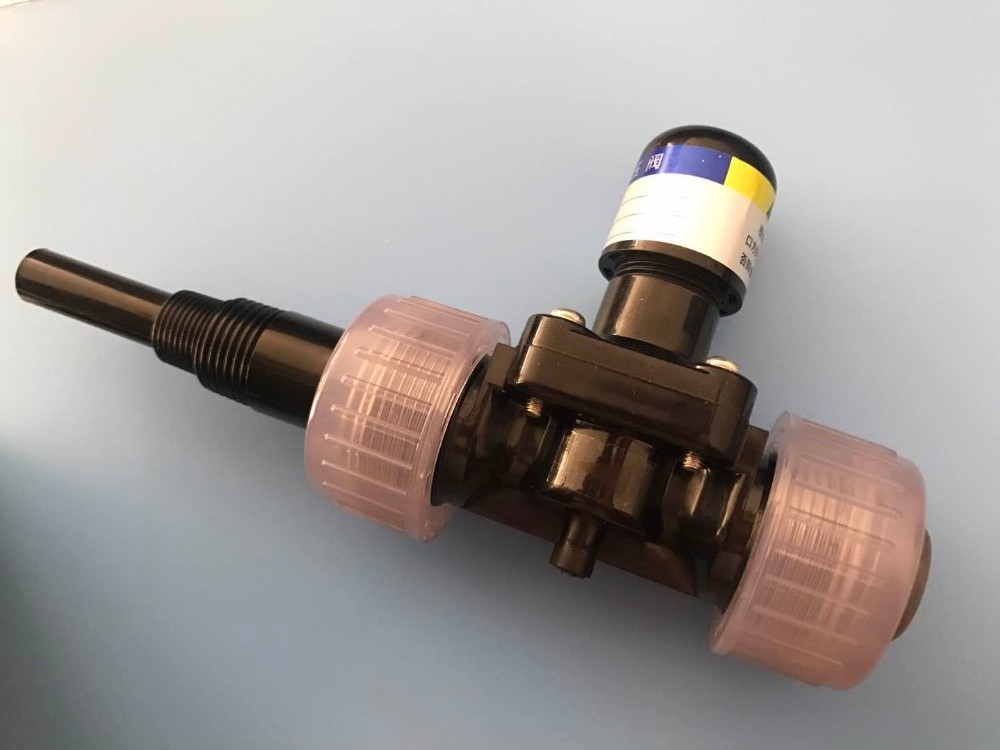

Back Pressure Control Valve Pressure Reducing Valve For Dosing Pump

-

Keyword:

-

Pressure Reducing Valve For Dosing Pump

-

Body material:

-

PVC

-

O-ring:

-

FKM

-

Pressure:

-

0.15Mpa

-

Color:

-

Black

-

Standard:

-

Customer Settings

-

Usage:

-

dosing pump

Quick Details

-

Type:

-

BALL VALVES, Washing Machine Valves, Water Heater Service Valves, Metal Check Valves, Plastic Check Valves, Pressure Vacuum Breaker, Safety Relief Valves, Temperature & Pressure Relief Valves, Pressure Reducing Control Valves, Water Pressure Reducing Valves, Pressure Regulators, Balancing Valves, Water Regulating Valves

-

Application:

-

General

-

Power:

-

Hydraulic

-

Structure:

-

Safety

-

Warranty:

-

2 years

-

Place of Origin:

-

Shandong, China, Shandong

-

Brand Name:

-

LANGO

-

Model Number:

-

BYF

-

Port Size:

-

R1/2 R3/8

-

Product name:

-

Back Pressure Control Valve Pressure Reducing Valve For Dosing Pump

-

Keyword:

-

Pressure Reducing Valve For Dosing Pump

-

Body material:

-

PVC

-

O-ring:

-

FKM

-

Pressure:

-

0.15Mpa

-

Color:

-

Black

-

Standard:

-

Customer Settings

-

Usage:

-

dosing pump

New F205 NEW Mini Pvc Back Pressure Control Valve PVDF Pressure Reducing Valve For Dosing Pump

Product Application

1, Compact structure and stable performance

2, Easy installation and debugging

3, Sensitive reaction and good reproducibility

4, Selective large size range DN10mm DN100mm

5, Small pressure difference by specially designed flow structure to avoid forming a closure

6, Easy to set the working pressure by regulating device

7, Installed in the bypassas overflow valve use

8, Used as anti siphon valve to prevent gravity under static conditions.

Main Features

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .