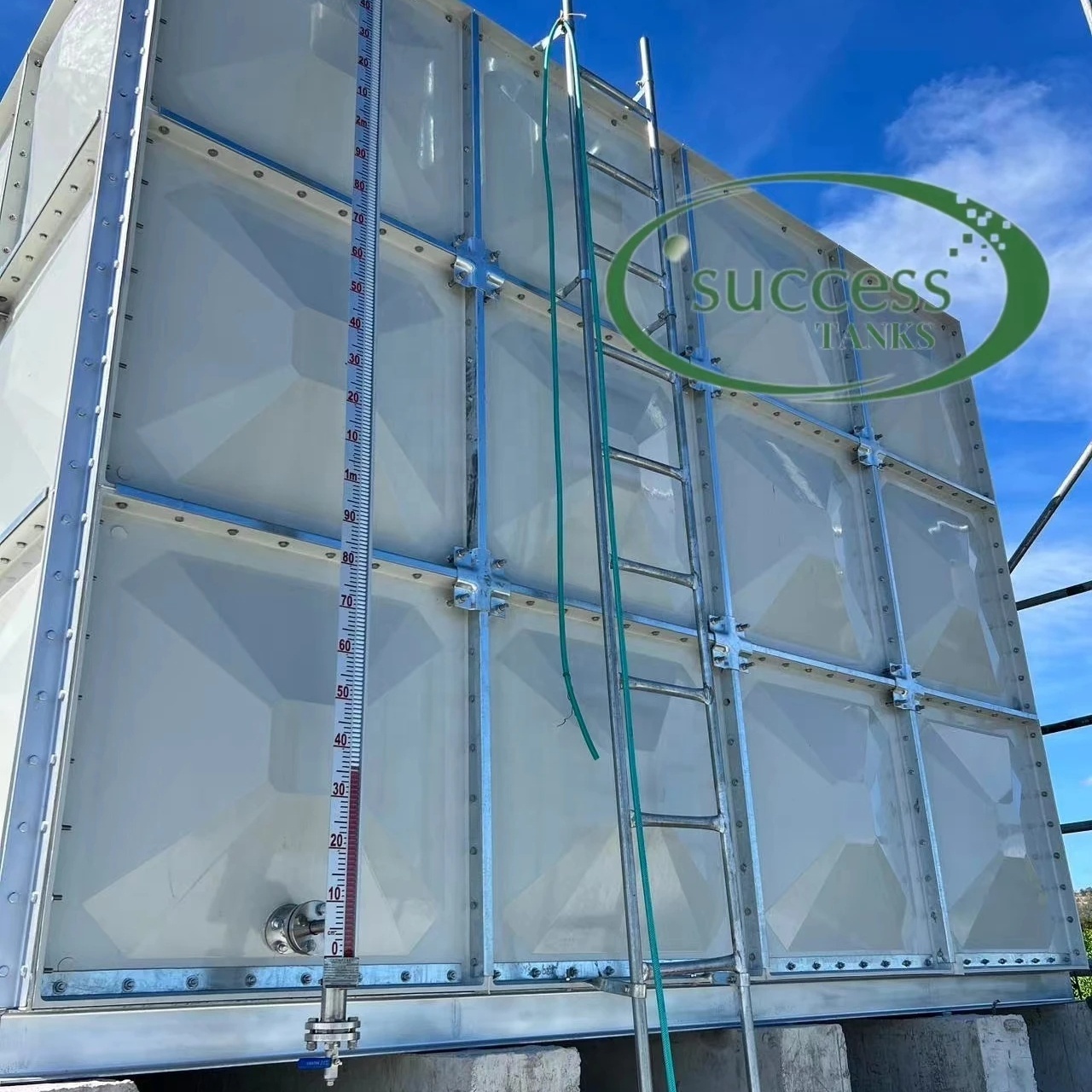

Glass Reinforced Plastic (GRP) water tanks are a safe, economical and clean way to store water. The GRP tanks are sturdy yet lightweight and can withstand the rigors of outdoor exposure. The GRP tank manufacturers make use of the SMC (Sheet Moulding Composite) Process to produce quality tanks. The process entails:

➽

Placing the right amount of fibre glass on thin f

iberglass

sheets.

➽ Mounting the combination in a hydraulic molding press.

➽ Application of regulated heat and pressure to make it frim and compact.

➽

During this cycle, different features such as ribs and other inserts are molded in as desired.

➽ The frame is then taken out of the press and cooled.

➽ A layer of resin and catalysts are added to the GRP frames and machine-spread between two sheets of GRP. This functions to give it its signature strength.

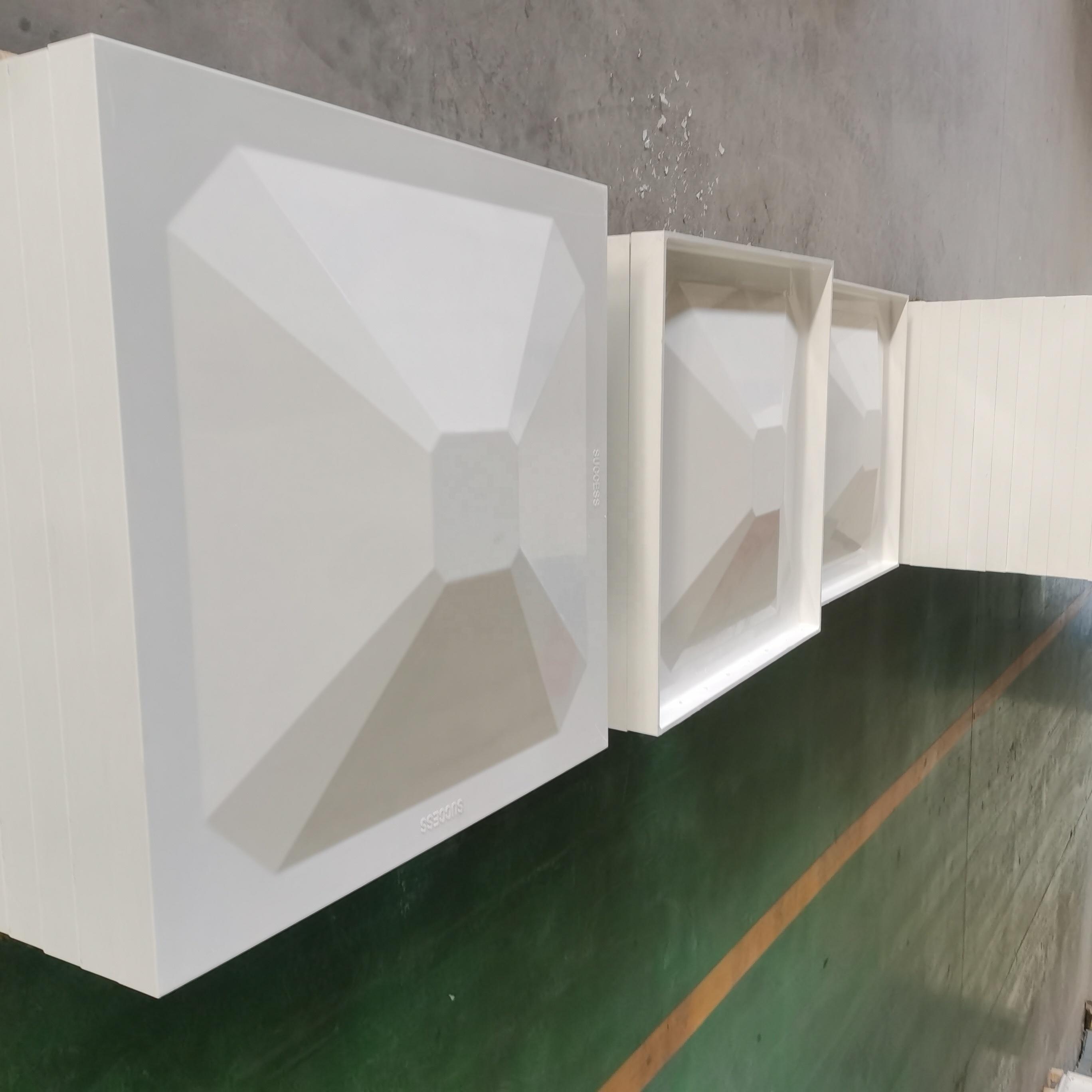

➽ The end result is a complex and high strength GRP Tank panel.

➽ The panels can now be drilled at the sides where they will be joined together with bolts and nuts to form GRP tanks.

➽ The frame is then taken out of the press and cooled.

➽ A layer of resin and catalysts are added to the GRP frames and machine-spread between two sheets of GRP. This functions to give it its signature strength.

➽ The end result is a complex and high strength GRP Tank panel.

➽ The panels can now be drilled at the sides where they will be joined together with bolts and nuts to form GRP tanks.