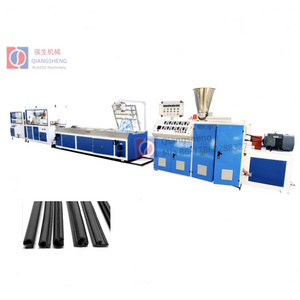

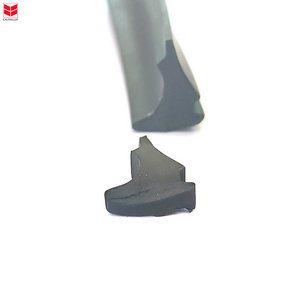

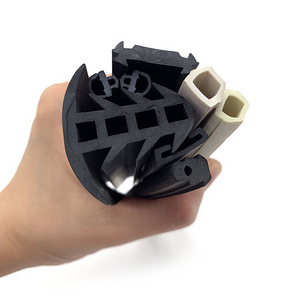

1. Supply PVC rubber refrigerator door and window sealing strip production line equipment PE silicone PVC seal production and processing equipment manufacturers supply PE luggage strip extruder, luggage molding equipment, luggage cartoon production line luggage plastic line production equipment, luggage production equipment, luggage plastic cartilage production line Equipment, luggage plastic parts, molybdenum production equipment, plastic molding machine, production equipment, luggage edge of the strip equipment, luggage embedded equipment, the supply of PVC silicone PVC seal production and processing equipment.

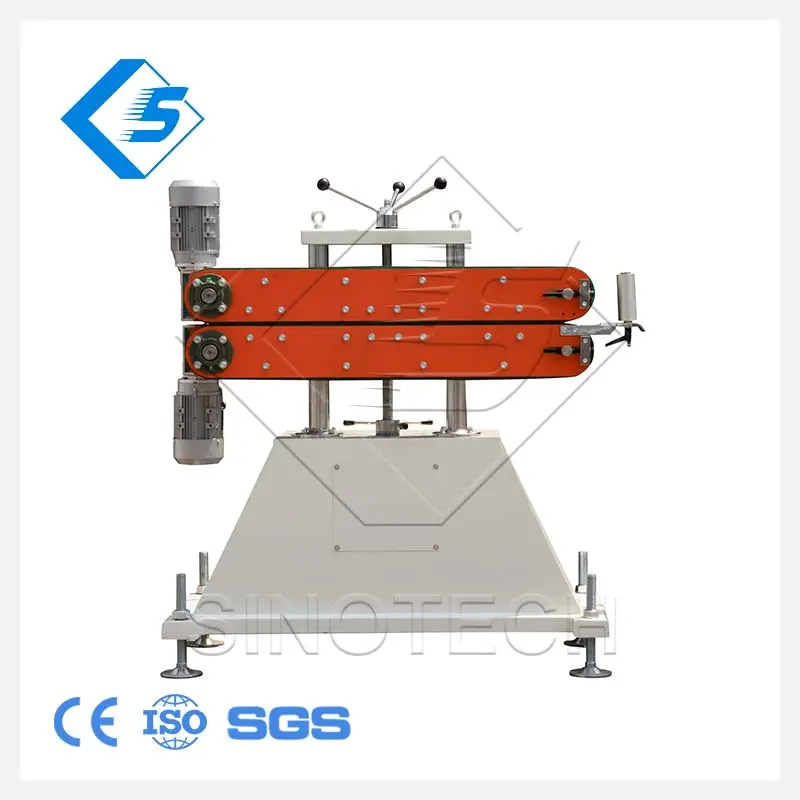

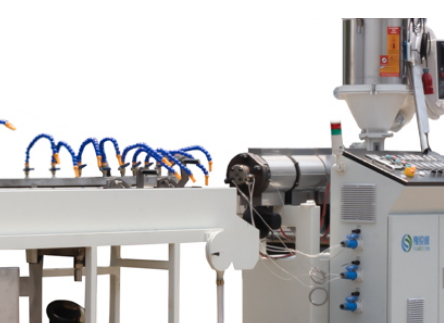

2. The PVC profile extrusion line is equipped with conical single-screw extruder. The production line has many advantages: material thawing even, small shear rate, high output, long service life, etc. The production line includes extruder, calibrator unit, haul-off unit, double station winder or stacking unit, etc.

2. The PVC profile extrusion line is equipped with conical single-screw extruder. The production line has many advantages: material thawing even, small shear rate, high output, long service life, etc. The production line includes extruder, calibrator unit, haul-off unit, double station winder or stacking unit, etc.