Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

100 rpm

-

Place of Origin:

-

Qingdao city,China

-

Brand Name:

-

YIERTAI

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

35m*6.5m*3.5m

-

Power (kW):

-

320

-

Weight:

-

50000 KG

-

Inverter:

-

ABB

-

Product name:

-

PP honeycomb sheet Extruder Machine

-

Name:

-

PP Hollow honeycomb sheet Extrusion Machine

-

Raw material:

-

PP Granules

-

Usage:

-

Plastic Sheet Extrusion

-

Product Type:

-

Sheet Extrusion Production

-

Keywords:

-

PP honeycomb sheet machine

-

Final product:

-

pp honeycomb sheet/board

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

35:1, 35:1

-

Screw diameter (mm):

-

130, 130

-

Screw Speed (rpm):

-

100 rpm

-

Place of Origin:

-

Qingdao city,China

-

Brand Name:

-

YIERTAI

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

35m*6.5m*3.5m

-

Power (kW):

-

320

-

Weight:

-

50000 KG

-

Inverter:

-

ABB

-

Product name:

-

PP honeycomb sheet Extruder Machine

-

Name:

-

PP Hollow honeycomb sheet Extrusion Machine

-

Raw material:

-

PP Granules

-

Usage:

-

Plastic Sheet Extrusion

-

Product Type:

-

Sheet Extrusion Production

-

Keywords:

-

PP honeycomb sheet machine

-

Final product:

-

pp honeycomb sheet/board

Product Description

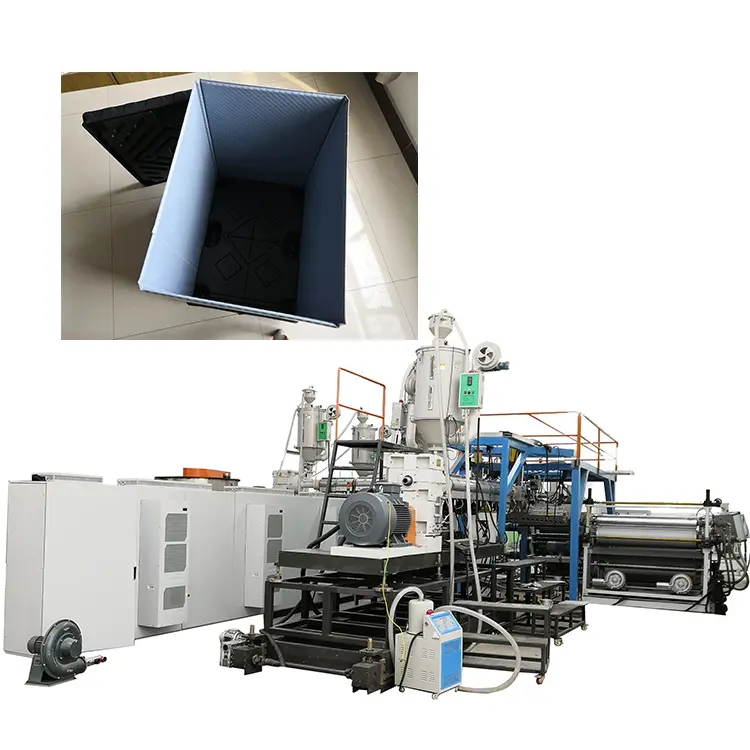

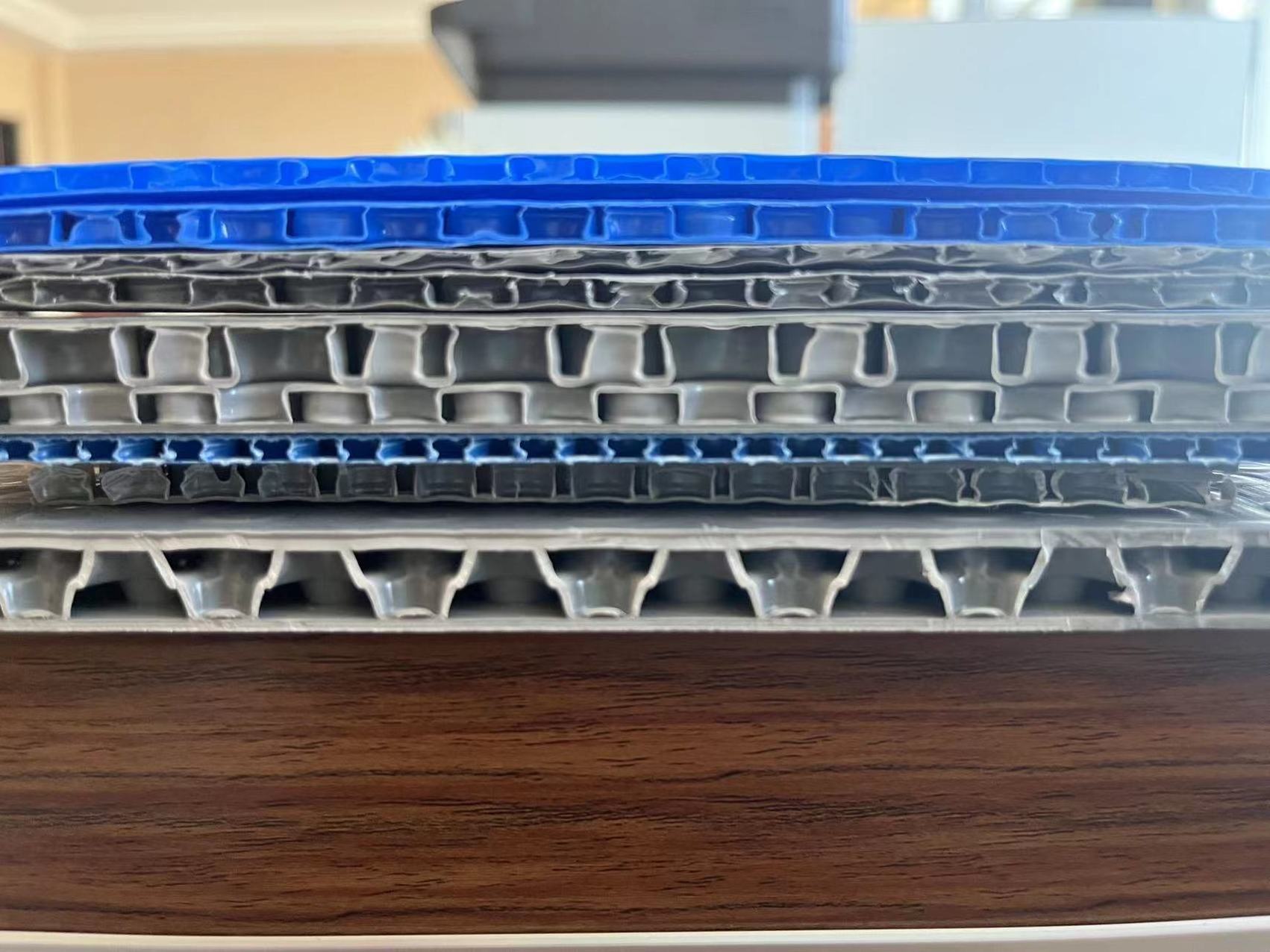

Plastic Hollow Honeycomb Bubble Board/Sheet Extrusion Machine

PP hollow sheet extrusion line can produce the sheet with the width of 1300mm-1800mm and thickness of 3-7.5mm.

Optimized electronic control system, original designed fast cooling and calibrating design, high-precision hauling off and cutting control .which make stably production, high efficiency.

Original designed and professional operation make the inside stress is been removed very well. So the sheet surface is very flat and the hollow hole is very neat.

Application

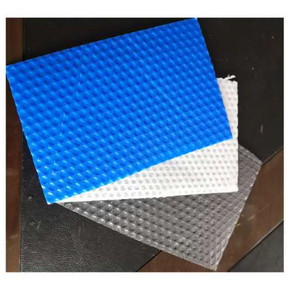

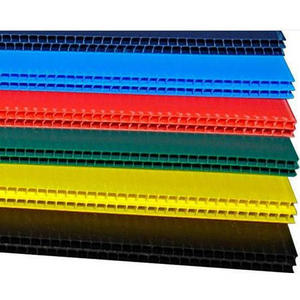

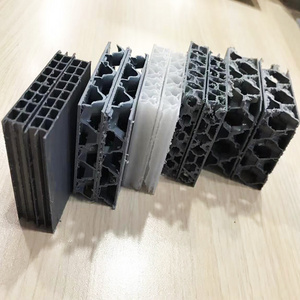

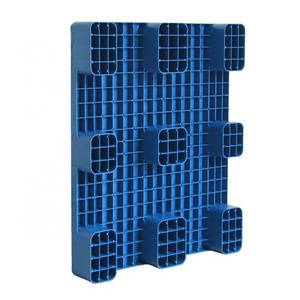

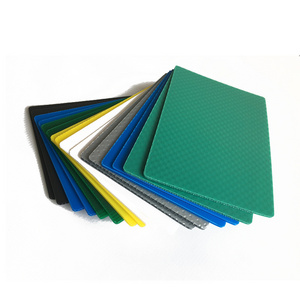

----PP honeycomb panels exhibits a unique sandwich structure with a honeycomb structure inside and one/two flat surfaces with either bubble finish or flat finish. It's light,waterproof and durable.

----It is widely used in turnover boxes,automotive, packaging,flightcases, floor protection,signboards, used as back & side plate, partitions, bulkheads and tables or interiors in general.

Specification

|

Model

|

Sheet width(mm)

|

Sheetthickness(mm)

|

Extruder

|

Motor power(kw)

|

|

YETFW-1300

|

1300

|

3-7.5

|

SJ-110/35

|

250-320

|

|

YETFW-1500

|

1500

|

5-6

|

SJ-130/35

|

240-320

|

|

YETFW-1800

|

1800

|

3-7.5

|

SJ-130/35

|

315-350

|

Detailed images

Products process:

Automatic feeding machine---single screw extruder---

Hydraulic net changer unit---

mold---

Vacuum setting table--

hall-off machine---

heating calibration unit---

Corona treatment machine

(Optional)---

Wind cooling calibration unit---

Two three-roller hall-off machine---

Automatic cutting machine---stack

er

Stir type dryer and Automatic feeding machine

High-efficiency

single screw extruder

The specially designed screw and the advanced electronic control system ensure excellent plasticization, high output and stable extruding. Our machine can add 70% filler to reduce cost.

The high-performance gearbox reducer has high torque, long life and low noise. The drive motor is an AC motor.

Hydraulic net changer unit

Screen changer ,Filter the impurities from the extruded material. The hydraulic fast screen changer makes the screen changing process fast and effective. Special sealing structure ensures the stable operation.

Extrusion mold

Mold adopts high-quality alloy steel. Throttling device ensures even pressure of material feeding at the mold lips. Differential action of up-down piece ensures even thickness of the sheet.

Equipped with: air pressure flow accuracy control device

Vacuum setting table

High quality forming mold, it ensures stably production and high-quality sheet. Vacuum forming. Vacuum system composes two independent sub-systems. Each sub-system is equipped with several three-point type fixed circulating vacuum lines. Calibrator is been special designed with fast cooling. It can get 6m/min speed for making 2mm thickness PP corrugated best quality sheet.

Primary six-roller hall-off machine

6 pairs Nitrile rubber rollers. Servo motor driving ensures stably forward and no damage on the sheet surface.

Infrared heating calibration unit

4 meters heating oven, which is made by stainless steel with auto temperature control. It is for removing the sheet inside stress. Make the sheet surface flat and hollow hole neat. The oven equips with an independent electronic control system which adopts famous brand temperature control meter, contactor and relays.

Corona treatment machine(Optional)

It is for treating the sheet surface, which ensures the pp hollow sheet can be printed well.

Wind cooling calibration unit

Fast air cooling device ensures the pp hollow sheet can be cooled in short time, so the sheet will not deformation.

Two three-rollerhall-off machine

3 pairs Nitrile rubber rollers. Servo motor driving ensures stably forward and no damage on the sheet surface.

Automatic cutting machine

Fixed length cutting, automatic cutting function. Servo motor driving.

Final Products

Hot Searches