- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Weight (KG):

-

980 KG

-

Production capacity (kg/h):

-

30-200

-

Feed size(mm):

-

<10

-

Discharge particle size(mesh):

-

80-300

-

Total power (kw):

-

13.5

-

Main speed (r/min):

-

~6000

-

Overall Dimension(mm):

-

4200*1200*2700

-

Weight (kg):

-

980

-

Core Component Warranty Period:

-

1 Year

-

Video Factory Inspection:

-

Provided

-

Type of marketing:

-

Provided

Quick Details

-

Output (kg/h):

-

30 - 1000 kg/h

-

Feeding Size (mm):

-

1 - 15 mm

-

Power (kW):

-

13.5

-

Place of Origin:

-

Henan, China

-

Weight (KG):

-

980 KG

-

Production capacity (kg/h):

-

30-200

-

Feed size(mm):

-

<10

-

Discharge particle size(mesh):

-

80-300

-

Total power (kw):

-

13.5

-

Main speed (r/min):

-

~6000

-

Overall Dimension(mm):

-

4200*1200*2700

-

Weight (kg):

-

980

-

Core Component Warranty Period:

-

1 Year

-

Video Factory Inspection:

-

Provided

-

Type of marketing:

-

Provided

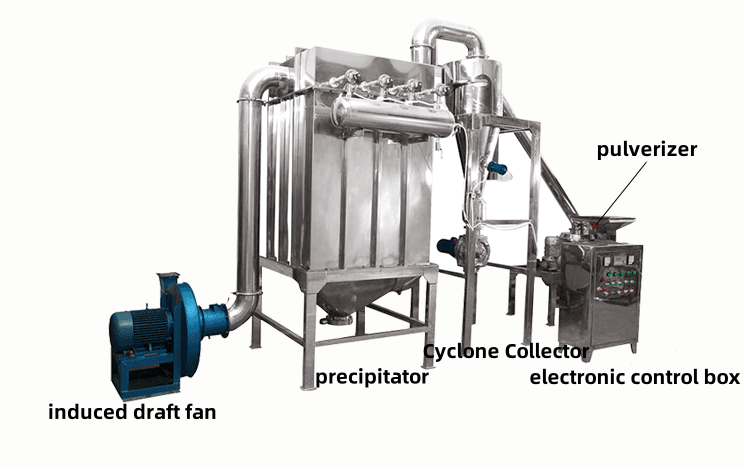

main application

WFJ-15/20/30/60 type ultra-fine pulverizing unit is mainly suitable for crushing

fineness in the 80-400 mesh, the output of larger crushing needs, very suitable

for food factories, chemical plants, high-precision crushing requirements,

crushing fineness can be adjusted at will. The pulverizing unit mainly consists

of the host, auxiliary machines, electronic control box consists of three parts,

compact design, reasonable structure, is a wind-selective, no screen.

Ultra-micro-grinding unit of the entire machine are manufactured from

high-quality stainless steel production. The machine is equipped with a

grading mechanism, which can make the crushing and grading completed

at once. Negative pressure conveying the heat generated in the cavity

during the crushing operation is constantly discharged, so it is also adapted

to the crushing of heat-sensitive materials. This machine has a wide range

of applications, the production process is continuous, and the size of the

discharged material is adjustable.

Various models of ultra-micro-grinding unit contains a host, adjustable-speed

spiral feeder, cyclone collector plus air hammer vibration device, bag-type dust

box plus air pulse device, induced draft motor to cause negative pressure.

High-power air-induced motor can not only make the conveying pipeline to

form a negative pressure, so that the fine powder to meet the requirements of

the wind automatically sucked into the pipeline, and a huge amount of wind

also takes away the heat generated in the crushing chamber, while the crushing

unit of the pipeline to play a strong cleaning effect. Cyclone collector outlet added

off the fan, no dust flying out of the mouth, to achieve the effect of clean,

environmental protection, savings.

target of crushing

WFJ-15/20/30/60 type ultra-fine pulverizing unit can deal with the pulverizing

and grading of many kinds of materials such as chemicals, food, cosmetics,

dyestuffs, resins, shells and so on, and the machine has reached the

international requirements. It can play a good crushing effect on various

materials such as rice, sugar, all kinds of beans, sedum wood, pepper, pepper,

coffee beans, cocoa beans, fennel, anise, cinnamon, cumin, cardamom, thyme

and so on. Oil content of particularly high materials such as sesame, walnuts,

peanuts, almonds, melon seeds, etc. can not be crushed separately. If you need

to crush materials with particularly high oil content, you need to mix them with other

materials that do not contain oil or low oil content, and the proportion of materials

with high oil content should be less than 25% as far as possible. If there are large

particles of high oil content materials, with the ultra-micro-grinding unit before

crushing, need to be crushed with a crusher or stainless steel crusher for crushing

(coarse crushing), and then use the ultra-micro-grinding unit for ultra-micro-grinding

Working Principle

Material from the material door through the screw conveyor into the crushing

chamber, by the high-speed rotating blade shear crushing, through the negative

pressure wind transport method to transport the material into the cyclone

separator, bag dust collector, discharged material dust from the vacuum

box through the bag filtration and recycling, the production process,

no dust flying, and can improve the utilisation rate of the material,

reduce the cost of the enterprise.

technical specification

| model number | WFJ-15 | WFJ-20 | WFJ-30 | WFJ-60 |

| Production capacity (kg/h) | 30-200 | 50-300 | 80-500 | 150-1000 |

| Feed size(mm) | 30-200 | <12 | <15 | <15 |

| Discharge particle size(mesh) | 80-300 | 80-300 | 80-300 | 80-300 |

| Total power (kw) | 13.5 | 17.5 | 46 | 81.5 |

| Main speed (r/min) | ~6000 | ~4800 | 46 | ~2800 |

| Overall Dimension(mm) | 4200×1200×2700 | 4700×1250×2900 | 6640×1300×3960 | 7500×2300×4530 |

| Weight (kg) | 980 | 1300 | 1500 | 32009 |

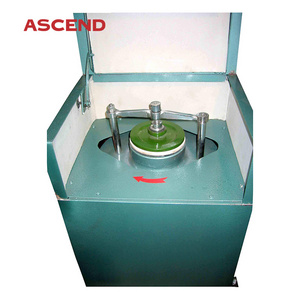

Product structure

product details