- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

38891-59-7

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

FOTMA

-

Model Number:

-

FM638

-

Product Name:

-

Ship Damping Coating

-

Application:

-

Ship/Bridge/Oil/Chemical Industry/Containers

-

Color:

-

Customized

-

Type:

-

primer

-

Feature:

-

Long Lasting

-

Certificate:

-

ISO9001

-

Package:

-

25 Kg/ Barrel

-

Delivery time:

-

15 days

Quick Details

-

CAS No.:

-

38891-59-7

-

Other Names:

-

Polyurethane Damping Coating

-

MF:

-

[CH(CH2cl)CH2o]N

-

EINECS No.:

-

38891-59-7

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

FOTMA

-

Model Number:

-

FM638

-

Product Name:

-

Ship Damping Coating

-

Application:

-

Ship/Bridge/Oil/Chemical Industry/Containers

-

Color:

-

Customized

-

Type:

-

primer

-

Feature:

-

Long Lasting

-

Certificate:

-

ISO9001

-

Package:

-

25 Kg/ Barrel

-

Delivery time:

-

15 days

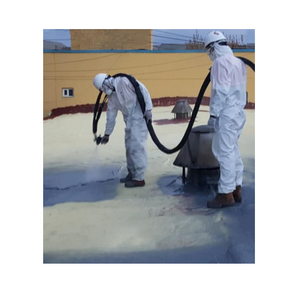

Polyurea Paint Polyurethane Painting Damping Coating For Ship/Boat

The damping coating for ships is a new type of environmental protection coating that can effectively reduce the vibration and noise of the structure. It consists of a damping layer and a constraining layer. The damping layer is a solvent-free two-component polyurethane coating; the constraining layer is a solvent-free two-component epoxy resin coating, in which a steel mesh is added to the constraining layer on the flatter parts of the ship's floor and floor to increase the damping performance.

Damping paint for ships is an active noise reduction material. Its principle is to convert vibration mechanical energy into thermal energy and dissipate it, so that the vibration energy that generates noise is greatly attenuated, that is, the vibration and noise are effectively controlled from the sound (vibration) source Therefore, the damping paint is mainly used in the places where vibration and noise are generated and the cabin where people often move, such as:

Main, auxiliary engine room, steering engine room, central control room and air-conditioning engine room of the ship;

Meeting rooms, cabins, restaurants and cabins that need to be quiet;

Engine shell and car body, fan shell and air duct, air conditioner compressor floor and other parts.

Damping paint for ships is an active noise reduction material. Its principle is to convert vibration mechanical energy into thermal energy and dissipate it, so that the vibration energy that generates noise is greatly attenuated, that is, the vibration and noise are effectively controlled from the sound (vibration) source Therefore, the damping paint is mainly used in the places where vibration and noise are generated and the cabin where people often move, such as:

Main, auxiliary engine room, steering engine room, central control room and air-conditioning engine room of the ship;

Meeting rooms, cabins, restaurants and cabins that need to be quiet;

Engine shell and car body, fan shell and air duct, air conditioner compressor floor and other parts.

Technical Datas:

| Color | Red, Black |

| Solid Content by Volume | 51% |

| Flash Point | 26ºC |

| Density | 1.1kg/L |

| Impact Test | ≥50kg.cm |

| Bending Test | ≤1mm |

| Salty Water Resistance 90d | No significant change |

| 10%NaOH Resistance , 30d | No significant change |

| 10%H2SO4 Resistance , 30d | No significant change |

| Salty Spray Resistance , h≥400 | No significant change |

Hot Searches