- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1220*175*170mm

-

Power (kW):

-

11 kW

-

Weight (KG):

-

55 KG

-

Operation:

-

Press Button

-

Product name:

-

Vulcanizing Machine

-

Usage:

-

Rubbr Vulcanization

-

Certification:

-

CE

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Beltwin

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

1220*175*170mm

-

Power (kW):

-

11 kW

-

Weight (KG):

-

55 KG

-

Operation:

-

Press Button

-

Product name:

-

Vulcanizing Machine

-

Usage:

-

Rubbr Vulcanization

-

Certification:

-

CE

For Rubber belt splicing,general there are 3 ways:

l

Fasteners mechanical

l

Cold Vulcanized splices

l

Hot vulcanized splices

Conveyor Belt Sectional Vulcanizers DSLQ-S offer great hot vulcanized splicing for all fabric ply belt s, steel cord belts . Can cover all splicing length . Working Pressure 100PSI and 200PSI and sectional press is portable to field site.

Production Information

1. Include water cooling system.

2. Operating pressures of 7 bar (100psi) to 14 bar (200psi) .

3. Portable design for filed working.

4. Durable Silicone Heating Element,uniform heating and easy maintenance.

5. Rubber pressure bag,can support working pressure 14 bar (200psi) and can accept water/air.

6. Completely automatic process programmed from the control unit (heating, dwell time and cooling).

7. Can combined for different width belt vulcanizing.

Optionals:

1. Silicone heating element

2. Rubber pressure bag

3. Control box and cables

4. Electric pump

5. Cross beams

If you need anything of sectional press,be free to contact us.

Specifications:

Heating platen

Beltwin heating platen by means of silicone heating elements and include durable composite insulating packaging. Sturdy electrical connectors and moisture-proof latch enhance press durability.

1. Platen can cover all rubber belt splicing area during splicing and keep the +/- 5 Degree Celsius variation in the platen surface cooking temperature.

2. Rapid Integral Water Cooling System, Water cooling system composed by a closed stainless steel circuit, that help circulate water all along the platens propelled by a water pump , allow temperature cooling down from 145C to 75C in 10-15 mins

H eating Element

Flexible & offer uniform heating

Silicone heating elements, durable composite insulating packaging, more safe.

It ’ s totally sealed, these heating elements can ’ t touch the air, longer life time.

Power connections are sealed for moisture resistance.

Easier Maintenance

Cross Beam (Traverse bars)

Th e beams are available in various profiles and lengths to provide a custom solution for your needs and manufactured out of quality extruded aluminum , light weight . We improve beams design to make sure the beam structure will keep as original, more safe. The beams include r ecessed high tensile steel nut/bolt assemblies, material 45# ; have safety design that can lock bolt & nut in the beam and e asy assemble by hand, no need use tension wrench to fix the nut & bolt. We also have E type bars if you need.

Pressure System

pressure bag use o ne-piece production and made from durable fabric reinforced rubber . Light Weight and new design with completed rubber, supply uniform pressure, also can used for both air and water pressure . Ensures uniform pressure over entire platen area.Air pressure up to 100 psi (7 kg/cm ² ) or water pressure for operating pressure up to 200 psi (14 kg/cm ² ).

Auto controller with cables

One set c ontrol box for 2 pcs platens . After heating temperature of both platens, the dwell time, the cooling temperature and the pressure have been set , the whole splicing process will run automatically . Automatic end-of-cycle buzzer. Include 2 SHIMADEN digital temperature control and indication, 1pc timer, 2 pcs amperemeters and one pc voltmeter . The same standard as Almex, easy exchange by your old Almex control system. More flexible and save cost. Accurate temperature and read out, CE approved electric components.

New electrical connections, reliable and safe. With earth connection. Plugs and sockets with "CE" mark

Electric Pump For Pressure & Cooling

The pump can increase /release water pressure and pumping water for water cooling system.

Components of sectional press

1.Control box;

2.Cross beam (Traverse bars);

3.Pressure uniform aluminum plate;

4.Pressure bag;

5.Upper heating platen;

6.Lower heating platen;

7.Safety pin;

8.Platen handle.

H eating Platen Drawing:

A= Length of heating platen along belt

B=Width of heating platen across the belt on the bias

C= Belt width

D= Bias angle

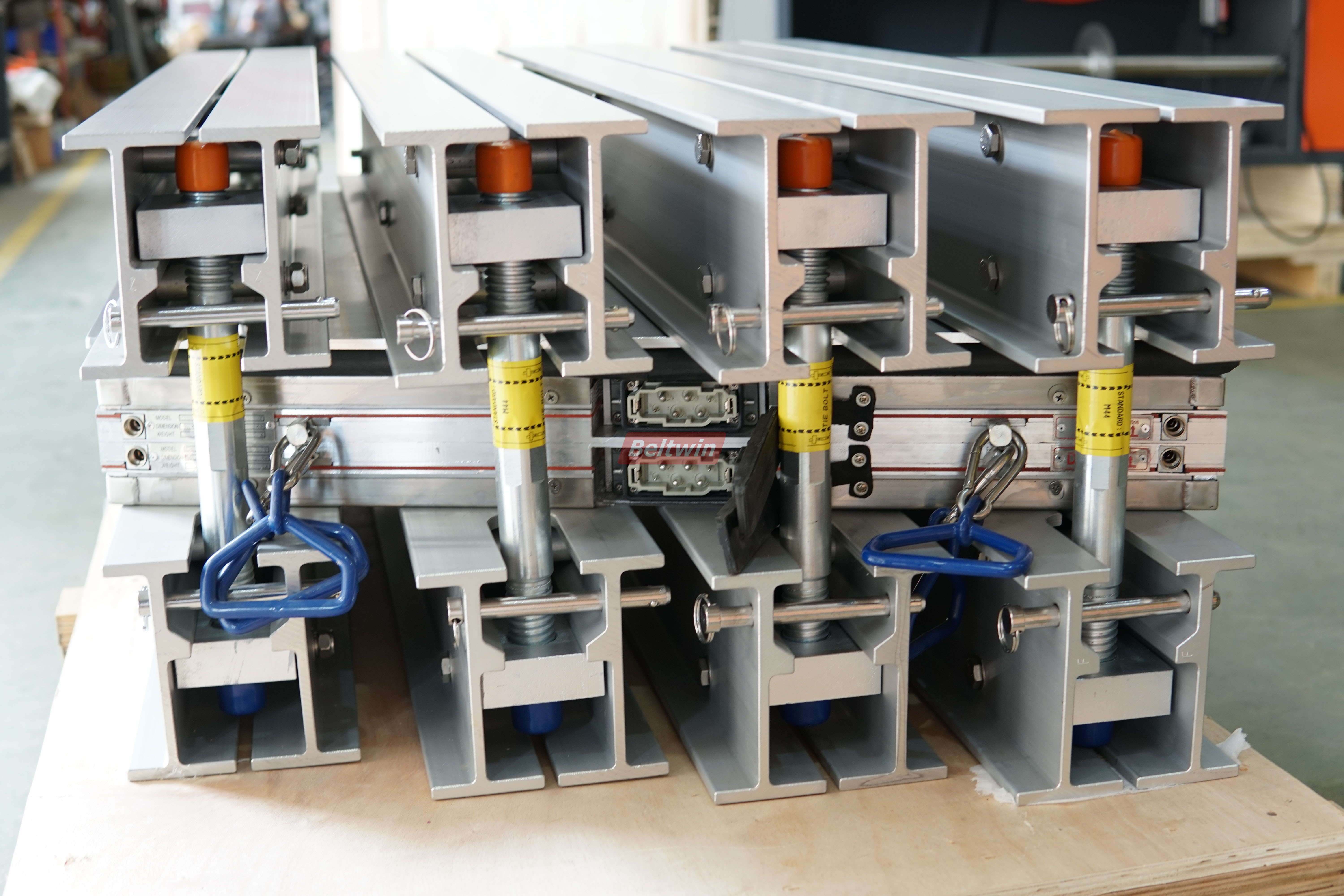

Packing photo of sectional press :

Customer Feedback Photo: