- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

10 KG

-

Power:

-

custommade

-

Dimension(L*W*H):

-

custommade

-

Power(W)::

-

customized

-

Function::

-

small workpiece shot blasting machine

-

Application::

-

Surface Cleaning

-

Power (V)::

-

220/380/400/440V

-

Name:

-

Q37 Hanger

-

Feature:

-

Metal Surface Cleaning

-

Color:

-

Customers Requirement

-

Blast wheel:

-

Low Noise Level

-

Blasting media:

-

Steel Grit

Quick Details

-

Place of Origin:

-

Shandong

-

Brand Name:

-

MeiLi

-

Core Components:

-

other

-

Weight (KG):

-

10 KG

-

Power:

-

custommade

-

Dimension(L*W*H):

-

custommade

-

Power(W)::

-

customized

-

Function::

-

small workpiece shot blasting machine

-

Application::

-

Surface Cleaning

-

Power (V)::

-

220/380/400/440V

-

Name:

-

Q37 Hanger

-

Feature:

-

Metal Surface Cleaning

-

Color:

-

Customers Requirement

-

Blast wheel:

-

Low Noise Level

-

Blasting media:

-

Steel Grit

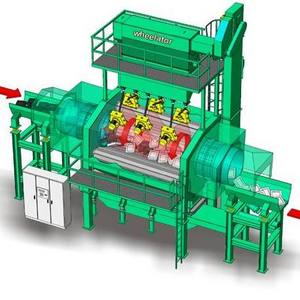

Products Description

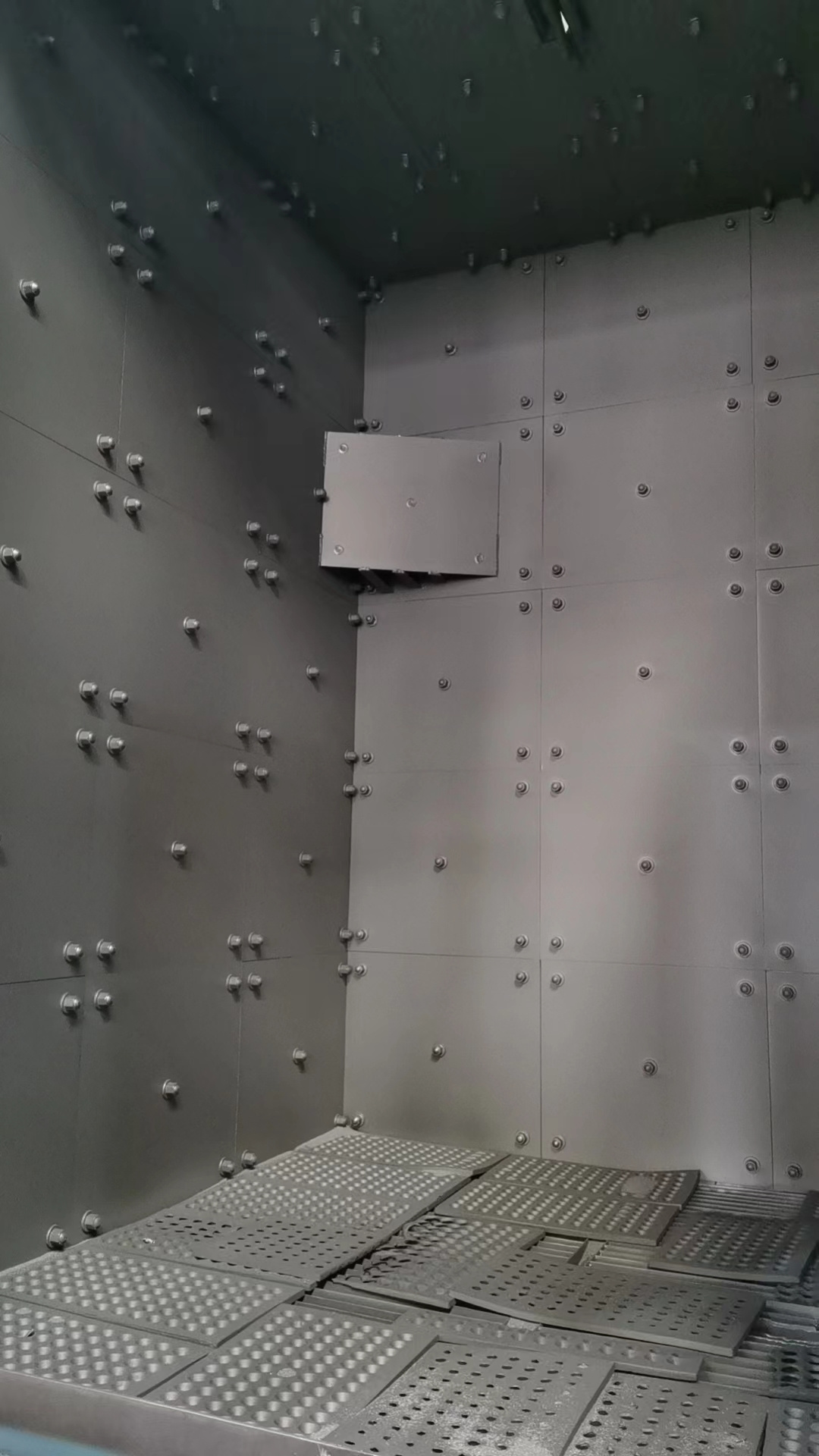

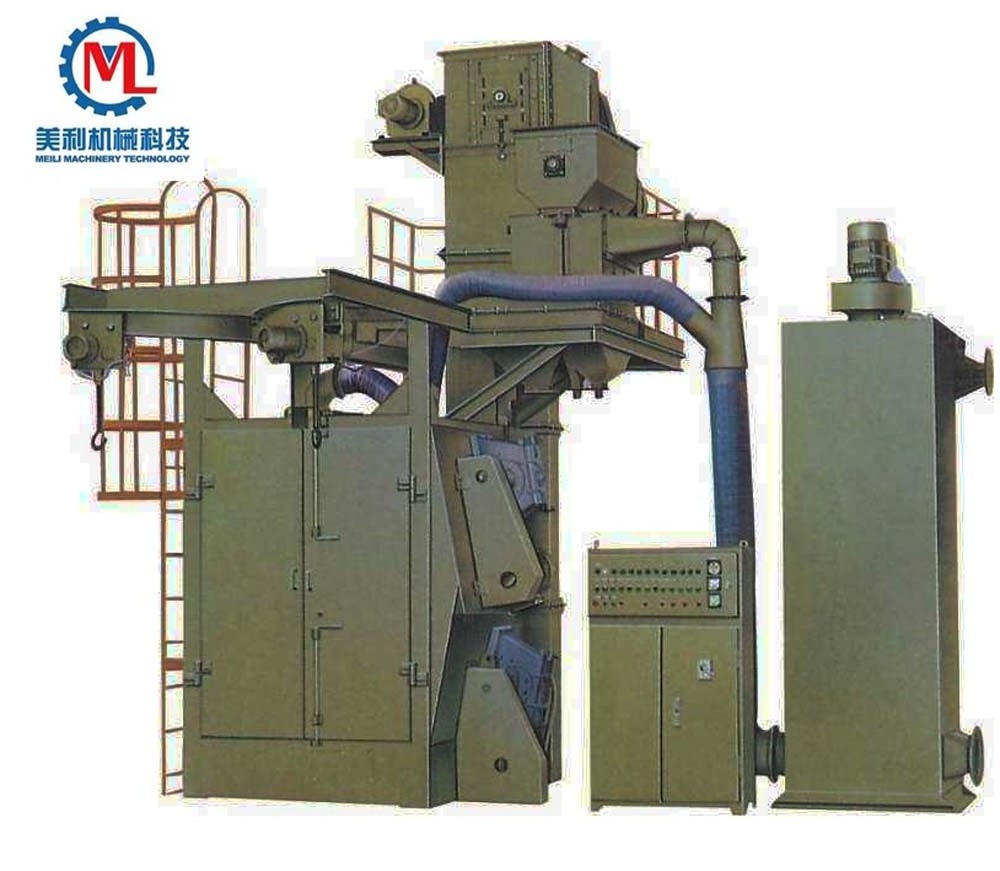

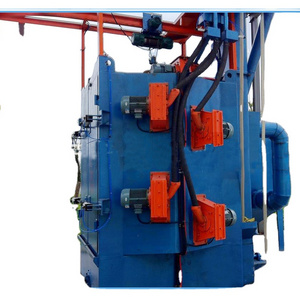

Hook shot blasting machine is a hook-type cleaning equipment with high productivity and is designed for shot blast cleaning of cast and forged parts and riveting welded parts. After the workpiece is shot blasted, the sand, rust, oxide scale and other debris on the surface fall off, and the workpiece can show the original color of the metal. This machine is also suitable for surface treatment of other workpieces with the same external dimensions. It is composed of shot blasting cleaning room, hoist, separator, screw conveyor, two shot blaster assemblies, projectile control system, hook walking track, hook system, rotation device, foundation, dust removal system and electrical control part.

|

Product Name

|

Hook type shot blasting machine

|

|

Material

|

Metal / coil / casting / small

|

|

Color

|

nickel white、Light green

|

|

Standard

|

Q37 series

|

|

Model

|

Q376/Q378/Q3710/Q3720

|

|

Brand

|

MeiLi

|

|

Used

|

The hook shot blasting machine has the characteristics of high production efficiency and is designed for shot blasting and forging surface cleaning. After the workpiece is shot blasted, the sand, rust, oxide scale and other debris on the surface fall off, and the workpiece can show the original color of the metal. This machine is also suitable for surface treatment of other workpieces with the same external dimensions.

|

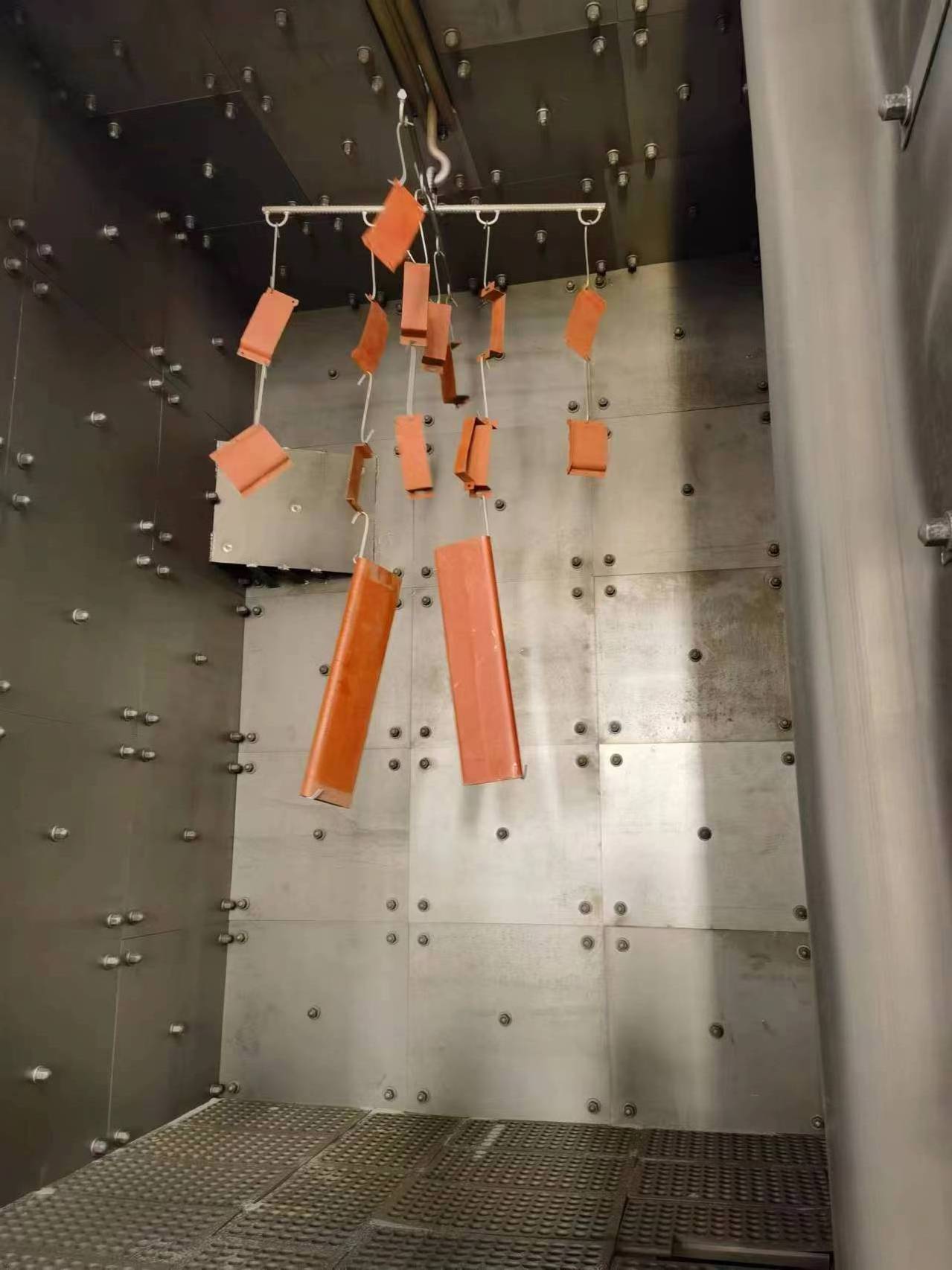

Details Images

Features

:

This series machine uses the method of multistep fixed-point rotation blasting and cleaning, removing the sand and oxide skin on the casting surface, to reappear metal color. It is mainly used in car accessories and bolster, side frame, coupling, and frame of trail hook vehicle parts, at the same time also can clean the casting and small batch workpiece with similar size.

Advantages:

1. Wide application, Easy to install and use.

2. Customized, Meet your needs.

3. Good stability, Low failure rate (technical maturity, technical precipitation, skilled workers).

4. Exquisite appearance (mature craft).

5. Large factories, Prompt delivery.

6. Strict quality inspection department.

7. Factory direct selling with competitive price.

8. Over 10 years' production experience.

9. Professional design team to serve you.

10. Mainly electrical control system adopts an international brand.

11. CE certificate assures you of our quality.

Manufacturing Technique

Function

Implement the cylinder delivery while cleaning the way, can often be removed by cleaning up the dirt from the outer wall of the cylinder, scale, rust, make the surface is bright and clean, and strengthen the workpiece surface, thus achieve the goal of improve the quality of workpiece surface and internal.

Product packaging

Hot Searches