- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

AC380V,50-60HZ,3PHASE

-

Dimension(L*W*H):

-

4260*2150*3300 MM

-

Warranty:

-

1 year warranty

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Processing:

-

Drilling machine

-

Certification:

-

CE, CE BV

-

Motor:

-

Yaskawa servo motor and Servo driver

-

Spindle:

-

ITALY Original 10 KW 5 axis spindle head

-

Working speed:

-

30 m/min

-

Control:

-

OSAI or Synthec control system

-

X.Y structure:

-

Gear wheel transmission

-

Product name:

-

fresadora cnc 5 eje

-

Weight:

-

7500 KG

-

Power:

-

10 KW

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

CHAODA

-

Model Number:

-

JC--5AXIS

-

Voltage:

-

AC380V,50-60HZ,3PHASE

-

Dimension(L*W*H):

-

4260*2150*3300 MM

-

Warranty:

-

1 year warranty

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Processing:

-

Drilling machine

-

Certification:

-

CE, CE BV

-

Motor:

-

Yaskawa servo motor and Servo driver

-

Spindle:

-

ITALY Original 10 KW 5 axis spindle head

-

Working speed:

-

30 m/min

-

Control:

-

OSAI or Synthec control system

-

X.Y structure:

-

Gear wheel transmission

-

Product name:

-

fresadora cnc 5 eje

-

Weight:

-

7500 KG

-

Power:

-

10 KW

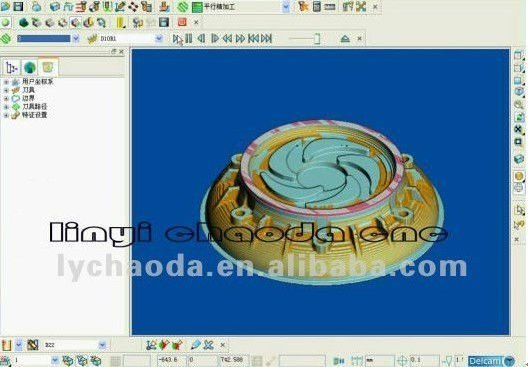

5 axes cnc contouring & milling machine / fresadora cnc 5 eje

Applications:

1. Mold industry: various large metalloid mould, especially suitable for

automotive foam mold, wooden ship model, wooden model aviation, rail

wooden mold, wooden mold train.

2. Instrument industry 3-d surface engraving and shape cutting of large-scale

instruments

3. Sign, plastics, wood, molds, etc

4. Furniture, general woodworking manufacturing

| Machine Features: | |

| X,Y,Z working area | 1200*2400*900mm |

| Table size | 1200*2500mm |

| Spindle | HS655 HSD spindle, 1000-24000rpm |

| Motor | Yaskawa Servo motor and driver |

| Moving mode | Table moving |

| C travelling | ±245 DEGREE |

| A travelling | ±120 DEGREE |

| Beam spacing(MM) | 4260 |

| Beam Height(MM) | 2150 |

| Vacuum pump | Dry Vacuum pump 5.5kw |

| product fixed form | vacuum table |

| Tool magazine | Round tool tool magazine (8 positions) |

| X, Y, Z Travelling Potioning Accuracy | ±0.02/300mm |

| X, Y, Z Travelling Repositioning Accuracy | ±0.05mm |

| Frame | Cast steel |

| X, Y structure | rack and pinion drive, Taiwan rail linear bearing from Japan |

| Max Rapid Travel Rate | 45,000mm/min |

| Max working speed | 30,000mm/min |

| Z Axis | 20m/min |

| C Axis | 20m/min |

| A Axis | 20m/min |

| Machine size | 4260*2150*3300 |

| Total Power(kw) | 24KW |

| Maximum lifting weights | 20T |

| Working voltage | AC380V/50Hz |

| Command languages | G code,F/S |

| Control system | OSAI / SYNTHEC |

| Collet | BT40 |

| Limit switch | Omron |

Applicable industriesMold industry:

various large metalloid mould, especially suitable for automotive foam mold, wooden ship model, wooden model aviation, rail wooden mold, wooden mold train.Instrument industry: 3-d surface engraving and shape cutting of large-scale instruments.

1. Diversified control processing speed can control the working speed, traveling speed, dropping tool speed, lowering tool speed, greatly improve the quality and efficiency.

Intelligent processing cross-border protection function can prevent mechanical collision due to excessive processing of design file.

2.Z-axis travel can be heightened to 2.1 meters, so that very suitable for processing large-scale three-dimensional surface..

3. Adopt Europe OSAI numerical control system, high machining accuracy and high speed. The Japan THK rails.and the Germany original rotating arm ensure the accuracy and strength of the mechanical

After Sales Service:

Training-----One technician will be assigned to client company for 3 working days free of charge. Customer is responsible for accomodation, food and air tickets.

Email--------24hours email support from Monday to Friday

Call----------24hours call support From Monday to Friday