- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

hechuang

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

6.5m*1.5m*1.8m

-

Weight:

-

9000 kg

-

Product name:

-

Roof Sheet Forming Machine

-

Usage:

-

Building Roof

-

Raw material:

-

PPGI PPGL GI GL

-

Shaft material:

-

High Grade No.45 Forged

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr12Mov Steel

-

Control system:

-

PLC(imported Brand)

-

Function:

-

Roof Usage

-

Color:

-

Customised

-

Advantage:

-

Easy Control

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

30 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

hechuang

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

6.5m*1.5m*1.8m

-

Weight:

-

9000 kg

-

Product name:

-

Roof Sheet Forming Machine

-

Usage:

-

Building Roof

-

Raw material:

-

PPGI PPGL GI GL

-

Shaft material:

-

High Grade No.45 Forged

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr12Mov Steel

-

Control system:

-

PLC(imported Brand)

-

Function:

-

Roof Usage

-

Color:

-

Customised

-

Advantage:

-

Easy Control

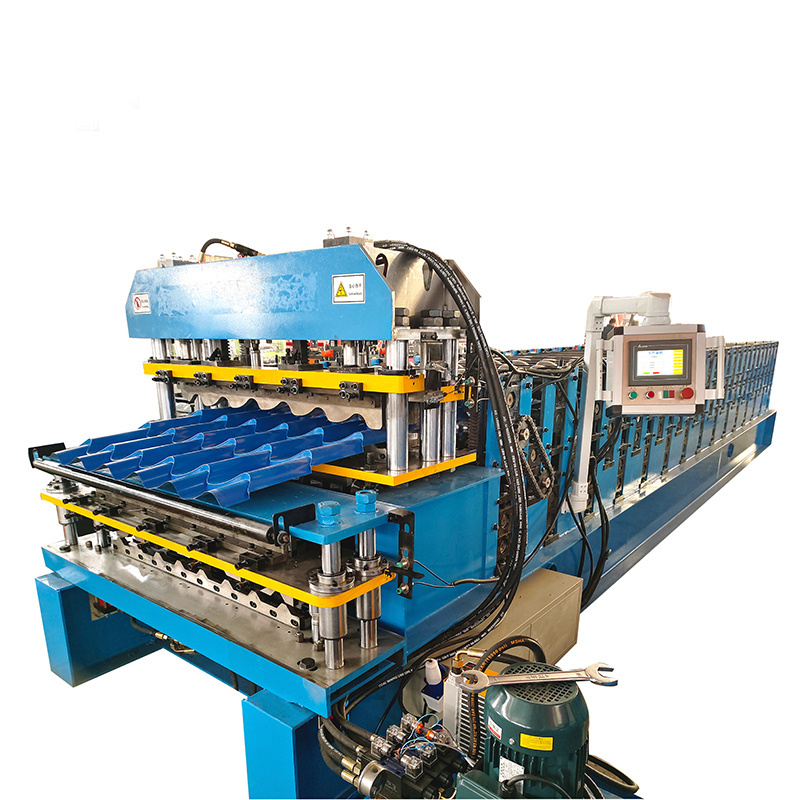

Specificatioon

|

Item

|

Three Layer Tile Making Machinery Cold Roll Forming Machine

|

|

Use

|

Roof/Wall

|

|

Production Capacity

|

25m/Min

|

|

Place of Origin

|

China

|

|

Brand Name

|

HC

|

|

Voltage

|

380v 50Hz 3Phases

|

|

Dimension(L*W*H)

|

6.5m*1.5m*1.8m

|

|

Weight

|

9 tons

|

|

Warranty

|

1Year

|

|

Rolling thinckness

|

0.2-0.8mm

|

|

Feeding width

|

1200mm

|

|

Main frame

|

Material:350H steel

|

|

Middle plate

|

16mm

|

|

Shaft

|

70mm

|

|

Rollers

|

45# steel Chrome Plated

|

|

Roller Station

|

13/15/15 stations

|

|

Transmission

|

Specifications:1 inch chain wheel with gear transmission

Processing :Quenching heat treatment Gear oil:18 # hyperbolic gear oil |

|

Main Motor

|

Power:7.5KW

|

Products Description

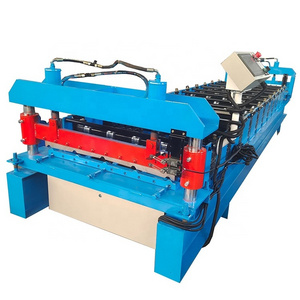

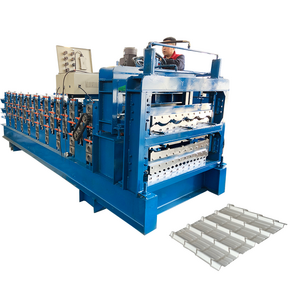

Three Layer Tile Making Machinery Cold Roll Forming Machine

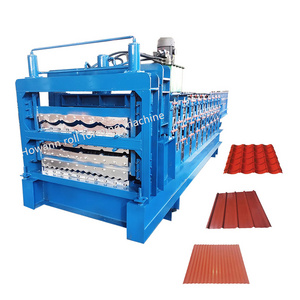

This layer roll forming machine one layer is IBR roof making machine, another is corrgated roof sheet roll forming machine, and third is glazed tile making machine.

Three different tile can produced by one machine, can Save space and cost.

The machine works by using a series of rollers to shape a flat sheet of metal into the desired trapezoidal shape. The process involves feeding the metal sheet through a set of forming rollers, which gradually bend and shape the metal into the high-ribbed profile. As the sheet progresses through the machine, additional rollers further refine the shape and ensure consistent dimensions and quality.

Details Images

Our company

Customer Photos

Product packaging

FAQ

1. what is your guarantee period?

Guaranteed against malfunctions due to manufacturing defects for 12 months from the date of loading.

2. Do you provide training for my workers?

The machine has been installed and tested well before shipping. It is easy to operate.

Normally speaking, our customer follows the instruction book and can operate the machine well.?

You can also come to our factory to check the machine and learn how to operate it before shipping. It only needs 2 hours and you

can operate well.

3. I do not know about the machine and do not know how to install it. Can you install the machine in my factory?

If you need us to send engineers to your factory, you will pay for the travel expense such as visas, round tickets, hotels, and

food Salary of 80 USD per day per person (from departure from our factory, until we are back to our factory). You also need to

take care of his safety.

4. What is included in the machine?

The process for work: decoiler→feeding→roll forming→measuring length→cutting to length→product to stand

The whole line includes a manual decoiler, roll forming machine, and product stand. when you get the machine in your factory, you

just need to do following 3 things, and then you can start working.

a. Put the machine on the flat level ground.

b. Inject gear oil and hydraulic oil.

c. Connect 3 phase electric wire.

Guaranteed against malfunctions due to manufacturing defects for 12 months from the date of loading.

2. Do you provide training for my workers?

The machine has been installed and tested well before shipping. It is easy to operate.

Normally speaking, our customer follows the instruction book and can operate the machine well.?

You can also come to our factory to check the machine and learn how to operate it before shipping. It only needs 2 hours and you

can operate well.

3. I do not know about the machine and do not know how to install it. Can you install the machine in my factory?

If you need us to send engineers to your factory, you will pay for the travel expense such as visas, round tickets, hotels, and

food Salary of 80 USD per day per person (from departure from our factory, until we are back to our factory). You also need to

take care of his safety.

4. What is included in the machine?

The process for work: decoiler→feeding→roll forming→measuring length→cutting to length→product to stand

The whole line includes a manual decoiler, roll forming machine, and product stand. when you get the machine in your factory, you

just need to do following 3 things, and then you can start working.

a. Put the machine on the flat level ground.

b. Inject gear oil and hydraulic oil.

c. Connect 3 phase electric wire.

Hot Searches