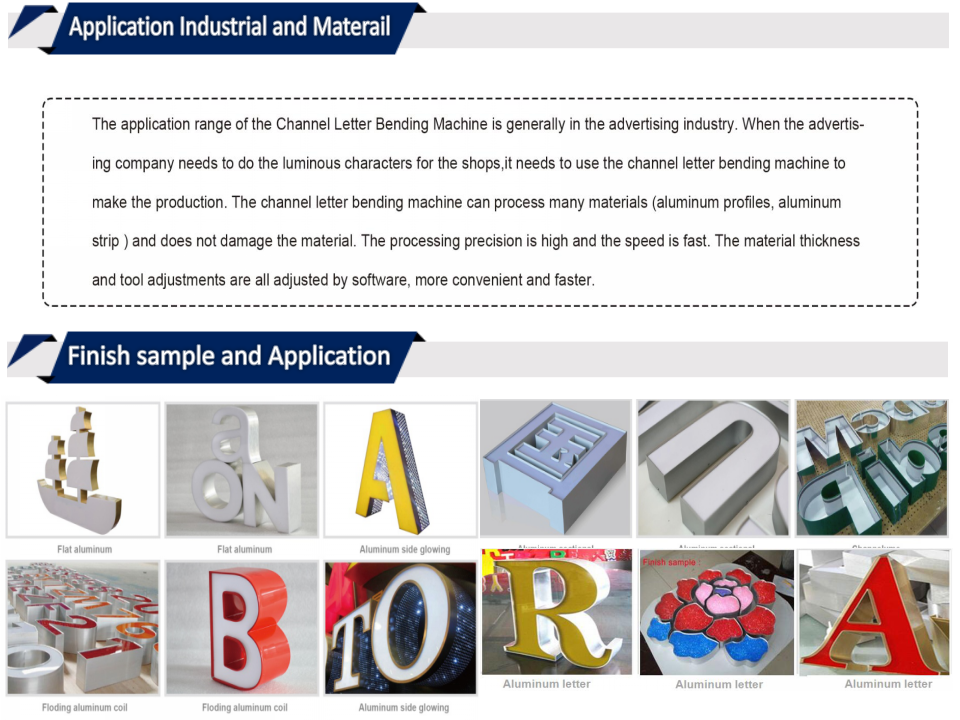

Application:

The application range of the Channel Letter Bending Machine is generally in the advertising industry. When the advertising company

needs to do the luminous characters for the shops,it needs to use the channel letter bending machine to make the production. The

channel letter bending machine can process many materials aluminum profiles, aluminum strip ) and does not damage the material.

The processing precision is high and the speed is fast. The material thickness and tool adjustments are all adjusted by software,

more convenient and fast.

Feature:

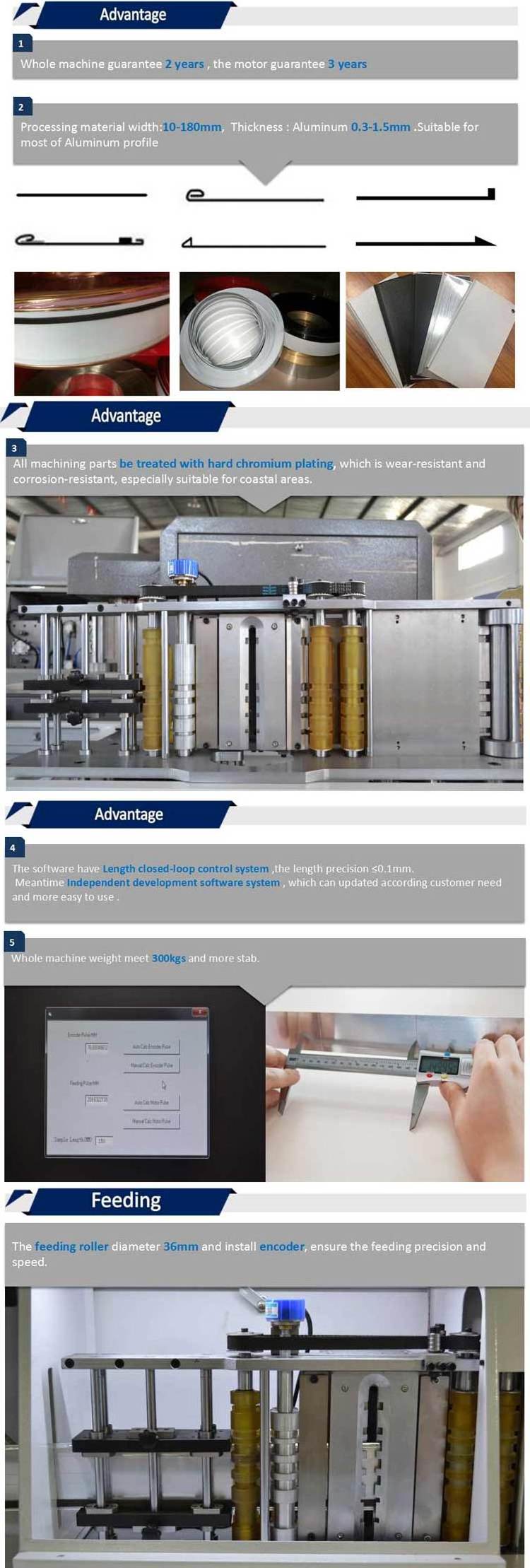

1.Whole machine guarantee 2 years , the motor guarantee 3 years

2. Processing material height 10-180mm, Thickness : Aluminum 0.3-1.5mm,

Suitable for most of Aluminum profile

3.All machining parts be treated with hard chromium plating,which is wear-resistant and corrosion-resistant, especially suitable

for coastal areas.

4.The motor and driver use the transformer with voltage digital display device to replace switching power,monitor the voltage

situation and remind customer to do the corresponding treatment when the voltage is unstable .

5. The software have Length closed-loop control system ,the length precision ≤0.1mm.

Meantime Independent development software system , which can updated according customer need and more easy to use .

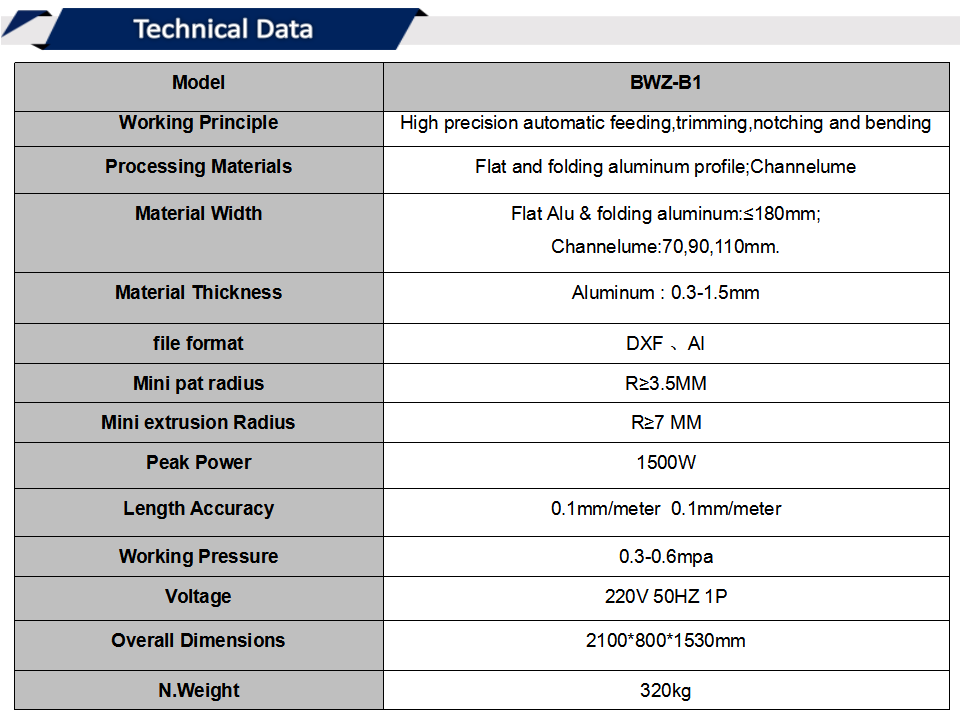

Technical datas:

- Product Details

- {{item.text}}

Quick Details

-

Products name:

-

Channel letter bending bender machine

-

Model:

-

BWZ-B1

-

Function:

-

Auto Feeding+bending+slotting

-

Available material:

-

Flat Alu and Folding Alu, Channelume

-

Certification:

-

CE

-

Voltage:

-

220V/50-60HZ/1P

-

Control system:

-

ADT

-

File format:

-

DXF AI PLT

-

Bending Radiua:

-

7mm

-

Keyword:

-

Channel letter bending

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

BaoYuanTong

-

Weight (KG):

-

320

-

Products name:

-

Channel letter bending bender machine

-

Model:

-

BWZ-B1

-

Function:

-

Auto Feeding+bending+slotting

-

Available material:

-

Flat Alu and Folding Alu, Channelume

-

Certification:

-

CE

-

Voltage:

-

220V/50-60HZ/1P

-

Control system:

-

ADT

-

File format:

-

DXF AI PLT

-

Bending Radiua:

-

7mm

-

Keyword:

-

Channel letter bending

Products Description

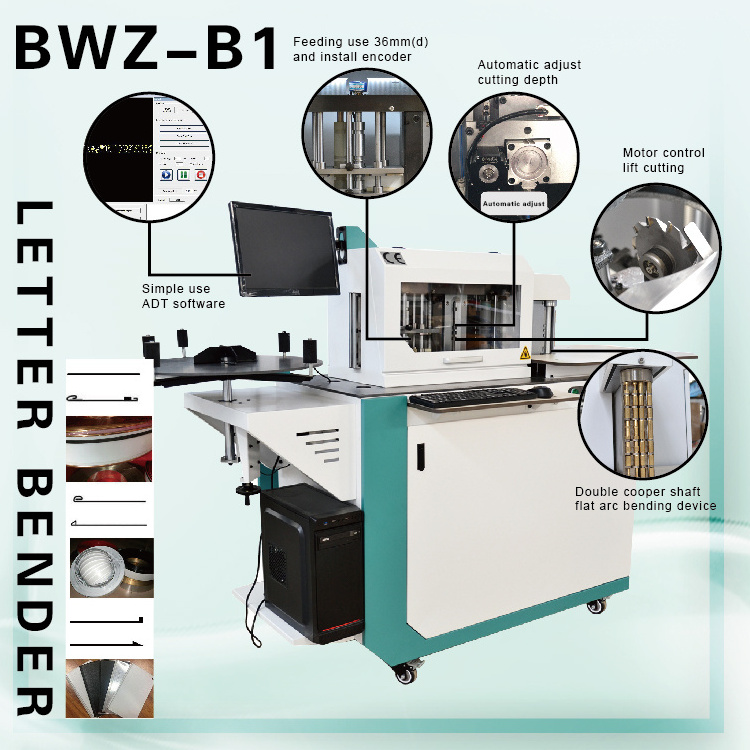

BWZ-B1 Channel Letter Bending Machine

|

Model

|

BWZ-B1

|

|

Function

|

Automatic feeding,slotting and bending

|

|

Applicable Material

Alu=Aluminum

|

Flat Alu,Folding Alu,Channelume

|

|

Material Width

|

Flat Alu:≤180mm Folding Alu:≤160mm

Channelume:70,90,110mm

|

|

Material Thickness

|

Aluminum:0.3~1.5mm

|

|

Bending Radius

|

7mm

|

|

Feeding

|

φ36mm feeding wheel+Guide material auxiliary+Encoder

|

|

Slotting System

|

Motor control

|

|

Bending

|

Coupled extrusion-Double copper shaft flat arc bender

|

|

Control System

|

ADT

|

|

Power

|

<1500W

|

|

Air Pressure

|

0.6MPa

|

|

File Format

|

Dxf, Ai,Plt

|

|

Working Voltage

|

220V/ 50-60HZ/1P

|

|

Net Weight(kgs)

|

270

|

|

Overall Size(mm)(L*W*H)

|

2100*800*1530

|

Why Choose Us

Company Experience

1.Founded in 1996, with registered trademarks "BAOYUANTONG" and "BYT".

2.Own more than 30 patents for invention, utility model and design.

3.Passed the "SGS certification" for 9 consecutive years, and all products have obtained the " Europe CE certification"

4.Exported to over 150 countries including the North America, Europe, South America, the Middle East,and have more than 2000

clients.

5.Provide one-stop procurement ,let customer’s purchase more efficient and safety.

6.According the customer different requirements ,provide equipment customized solved plan and sample making .

Sales Service

1.Technical people have professional english ability and directly with customer communication.

2.24H/7D on line service , when you need we all will be here .

3.Before delivery , accept the international third party finish inspection .

4.Regular return visits to customers for technical guidance, and get high praise from customers.

5.For the products making , have professional technical engineer provide process guide .

Various Training Service

1.Provide U disk with detailed operation manual and video.

2.Via on line chat way service(QQ,whatsapp,wechat) for customer in any time.

3.Via teamviewer remote control software to provide on line guidance.

4. Customer come to our factory for learning how to operate the machines.

5.Engineer can go aboard for training if customer needed.

Optional Parts

Customer feedback

Packing & Shipping

Packing:

1.After the completion of machinery production, the factory inspectors shall check and put the equipment into storage.Before the delivery of the equipment, the after-sales engineer shall conduct secondary inspection and ensure the quality of the machine meets the customer's requirements

2.Clean the whole machinery , protect the parts that need oil, and check the related parts again .

3. Anti-collision package edge: All parts of the machine are covered with some soft materials.

Whole film packaging machine: Avoid all damage that may occur during delivery. Then we will cover the plastic package tightly to ensure that the soft material is covered intact, also avoiding water and rust.

4. Fumigation wooden box:Our wooden box is fumigated, do not need to check the wood, saving the transport time and money.

Hot Searches