Our Seamless Carbon Steel Pipes stand as fortresses of strength, engineered to withstand the most formidable pressures. Crafted with meticulous precision, these pipes excel where others falter, providing a robust foundation for industries operating at the very limits. Characterized by their inherent resistance to deformation and steadfast structural integrity, our pipes serve not merely as components, but as the very pillars of industrial resilience.

- Product Details

- {{item.text}}

Quick Details

-

Oiled or Non-oiled:

-

Customized

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HYT

-

Outer Diameter:

-

20 - 200 mm

-

Thickness:

-

1 mm ~ 60 mm

-

Grade:

-

A53 A106 A179 A333 A519 A500 A335

-

Pipe Process Type:

-

Seamless/Welded

-

Seamless Process:

-

Hot rolled, cold drawn, cold rolled, etc.

-

Welded Process:

-

ERW, SAW, EFW, etc.

-

Shape:

-

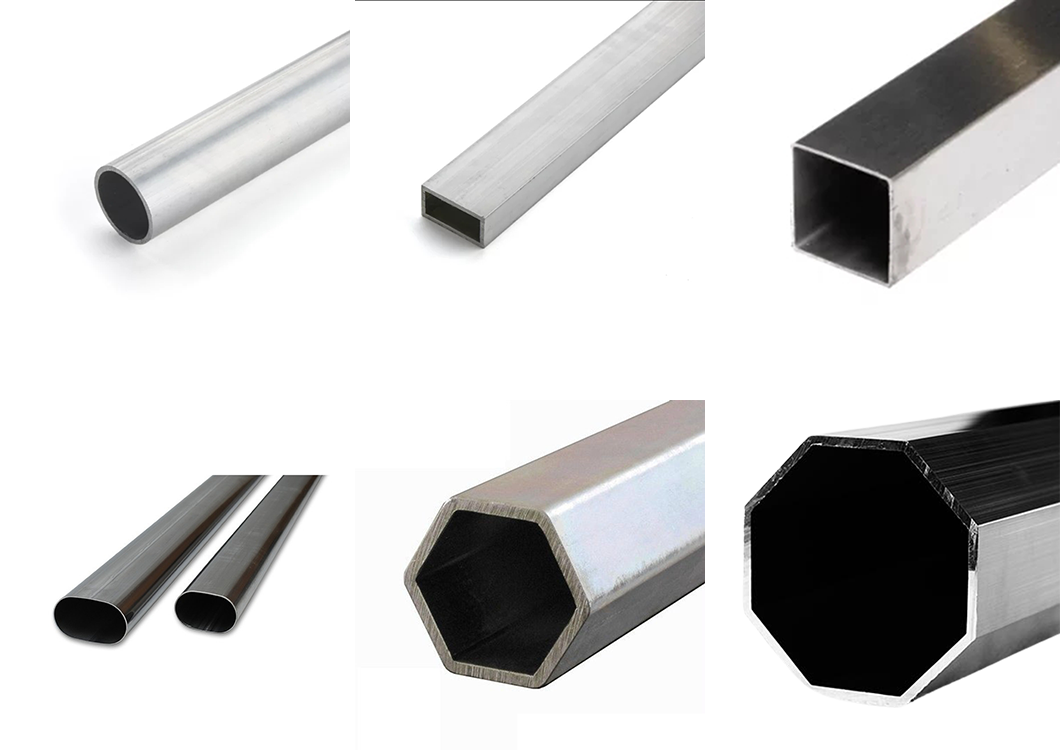

Round, Square, Rectangular, Oval, Hexagonal, etc.

-

OD:

-

6mm-2500mm

-

WT:

-

1mm-150mm

-

Application Industry:

-

Oil and Gas, Construction, Water Supply and Treatment, Automotive,

-

Pipe Ends:

-

Plain End (PE), Beveled End (BE), Threaded End (TE)

Quick Details

-

Section Shape:

-

Round

-

Surface Treatment:

-

Hot Rolled/Cold Rolled/Cold Drawn

-

Tolerance:

-

±5%

-

Oiled or Non-oiled:

-

Customized

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HYT

-

Outer Diameter:

-

20 - 200 mm

-

Thickness:

-

1 mm ~ 60 mm

-

Grade:

-

A53 A106 A179 A333 A519 A500 A335

-

Pipe Process Type:

-

Seamless/Welded

-

Seamless Process:

-

Hot rolled, cold drawn, cold rolled, etc.

-

Welded Process:

-

ERW, SAW, EFW, etc.

-

Shape:

-

Round, Square, Rectangular, Oval, Hexagonal, etc.

-

OD:

-

6mm-2500mm

-

WT:

-

1mm-150mm

-

Application Industry:

-

Oil and Gas, Construction, Water Supply and Treatment, Automotive,

-

Pipe Ends:

-

Plain End (PE), Beveled End (BE), Threaded End (TE)

Product Specification

|

Product Type

|

Pipe/Tube/Tubing

|

|

|

|

|||

|

Pipe Process Type

|

Seamless: Hot rolled, cold drawn, cold rolled, etc.

Welded: ERW, SAW, EFW, etc. |

|

|

|

|||

|

Standard

|

DIN, BS, EN, ISO, GB, AISI, SAE, GOST, IS, KS, ANSI, AFNOR, UNI, CSA, AS/NZS.

|

|

|

|

|||

|

Standard Specification and Grades

|

Stainless Steel:

A213,A269,A270,A312,A358,A554,A790. TP304, TP304L, TP316, TP316L, TP321, TP347, TP309S, TP310S, TP317L, TP347H MT304, MT304L, MT316, MT316L, MT309S, MT310S, MT317L, MT321, MT347, MT430 T2, T5, T9, T12, T22, T91 S31803, S32205, S32750, S32760, S32304. Carbon and alloy Steel: ASTM A53 A106 A179 A333 A513 A519 A335 A500 A53 Grade A/B A106 Grade A/B/C A333 Grade 1/3/6 A513 Type 1/2/5 1010 1020 1026 1035 1045 4130 4140 A335 P5 P9 P11 P22 P91 A500 Grade A/B/C/D Aluminum and Aluminum Alloy: ASTM B241, ASTM B210, ASTM B221, ASTM B234, ASTM B345 6061, 6063, 2024, 7075, 5052, 5083, 5086, 3003, 1100, 7050 Nickel-based Alloy: ASTM B167, ASTM B444, ASTM B407, ASTM B622, ASTM B829 Alloy 400, Alloy 600, Alloy 625, Alloy 800, Alloy 800H, Alloy 825, Alloy C276, Alloy 20, Alloy 200, Alloy X Pure Copper and Copper Alloy: ASTM B42, ASTM B88, ASTM B280, ASTM B75, ASTM B251 C10100, C10200, C11000, C12200, C23000, C26000, C27000, C33000, C44300, C70600 Pure Titanium and Titanium Alloy: ASTM B861, ASTM B862, ASTM B338, ASTM B337, ASTM B523 Grade 1, Grade 2, Grade 3, Grade 4, Grade 5 (Ti 6Al-4V), Grade 7, Grade 9 (Ti-3Al-2.5V), Grade 11, Grade 12, Grade 23 (Ti 6Al-4V ELI) |

|

|

|

|||

|

Section Shape

|

Round, Square, Rectangular, Oval, Hexagonal, etc.

|

|

|

|

|||

|

Size

|

Round Pipe/Tube

WT: 1mm-150mm(SCH10-XXS) OD: 6mm-2500mm (3/8"-100") Square Pipe/Tube WT: 1mm-150mm(SCH10-XXS) OD: 4mm*4mm-800mm*800mm Rectangular Pipe/Tube WT: 1mm-150mm(SCH10-XXS) OD: 6mm-2500mm (3/8"-100") |

|

|

|

|||

|

Length

|

4000mm,5800mm,6000mm,12000mm,or as required.

|

|

|

|

|||

|

Customization

|

Our company proudly offers comprehensive customization services. Beyond the material grades mentioned in the table above, we also cater to unique and lesser-known metal materials. We welcome you to reach out for further discussions and collaborations.

|

|

|

|

|||

|

Brand

|

HYT

|

|

|

|

|||

|

Origin

|

China

|

|

|

|

|||

|

Application Industry

|

Oil and Gas, Construction, Water Supply and Treatment, Automotive, Power Generation, etc.

|

|

|

|

|||

|

Surface Treatment

|

Acid pickling, Wire drawing, Polishing, Sandblasting, Shot blasting, Electrochemical polishing, Titanium plating, PVD (Physical Vapor Deposition), Chemical coloring, Heat treatment, Annealing.

|

|

|

|

|||

|

Surface Finish

|

NO.1, 2D, 2B, BA (Bright Annealed), NO.3, NO.4, HL (Hair Line), NO.7, NO.8, SATIN.

|

|

|

|

|||

|

Color

|

Silver (Natural Steel), Black (Coated or Oxidized), Galvanized (Zinc), Green (Coated), Blue (Coated), Red (Coated), Yellow (Coated), White (Coated).

|

|

|

|

|||

|

Pipe Ends

|

Plain End (PE), Beveled End (BE), Threaded End (TE), Grooved, Bell End, Tapered, Expanded.

|

|

|

|

|||

|

Tolerance

|

As standards’ Requirements

|

|

|

|

|||

|

Test

|

Support Third-party Test.

|

|

|

|

|||

|

Certification

|

GB/T19001-2016/ISO9001:2015

GB/T24001-2016/ISO14001:2015 GB/T 45001-2020/ISO 45001:2018 |

|

|

|

|||

|

Processing Service

|

Cutting, Bending, Threading, Welding, Grooving, Coating, Drilling, Galvanizing, Heat Treatment, Punching.

|

|

|

|

|||

|

Sample

|

Free Sample Available

|

|

|

|

|||

|

Stock Status

|

Continuous Supply Of Spot Products

|

|

|

|

|||

|

MOQ

|

1 Ton

|

|

|

|

|||

|

Packaging

|

Bundled, Wooden Cases, Plastic Wrapping, Plastic Caps, Palletized, Shrink Wrapped, Plastic Bagged, Steel Crates, Loose, Boxed.

|

|

|

|

|||

|

Port

|

Shanghai

|

|

|

|

|||

|

Delivery Term

|

EXW, FOB, FCA, etc.

|

|

|

|

|||

|

Delivery Time

|

3-5 days for the regular models, and 7 to 10 working days for the special sizes and processing

|

|

|

|

|||

|

Payment Term

|

T/T, L/C, D/P, etc.

|

|

|

|

|||

|

Customization

|

Customization Available

|

|

|

|

|||

Steel Pipe Section Choice

Round, Square, Rectangular, or Special Shape

Understand the structural superiority and adaptability of our carbon steel pipes, meticulously engineered to meet diverse industrial needs. Our product range is distinguished by its variety of cross-sectional shapes, ensuring a precise match for every application.

Our round pipes offer streamlined flow and uniform strength, making them ideal for fluid transport and high-pressure tasks. The square and rectangular pipes provide enhanced strength and rigidity, perfect for structural applications demanding durability and stability.

For specialized projects, our custom-shaped pipes are the solution, designed to meet unique specifications with precision and efficiency. These pipes combine functionality with customizability, catering to specific industry requirements.

Choose our carbon steel pipes for a reliable, versatile solution in your industrial applications. Engineered for performance, our pipes are the foundation for projects that demand quality and precision.

HYT Carbon Seamless Steel Pipe

Strength & Pressure Resistance

Corrosion and Heat Resistance

Crafted for excellence, our pipes stand as bulwarks against the elements. Each pipe is coated with a layer of innovation, offering unmatched corrosion resistance, ensuring longevity and unwavering performance even in the most aggressive settings. Facing scorching heat or freezing temperatures, our Seamless Carbon Steel Pipes retain their composure, delivering steadfast service in the face of adversity.

Customizability and Versatility

In a landscape marked by diverse challenges, a one-size-fits-all approach falls short. This is why our Seamless Carbon Steel Pipes come with a commitment to customization. Tailored to meet your distinct needs, our pipes offer a range of diameters, wall thicknesses, and lengths. With a variety of surface treatments and material grades at your disposal, the specific requirements of your industry are not just met; they are precisely catered to.

Product Category

Hot Rolled Seamless Steel Pipe

Empowering Structures with Heat-Forged Precision

Discover the robustness forged in the fires of innovation with our Hot Rolled Seamless Steel Pipes. Born from the heat that molds strength and versatility, these pipes are the epitome of endurance. The hot-rolled process ensures a malleable yet durable structure, perfect for industries that demand a blend of flexibility and resilience. With a seamless finish, these pipes offer a uniform structure, free from any weak points, ensuring a steadfast performance under pressure.

Cold Drawn Seamless Steel Pipe

Precision-Crafted for Performance at its Peak

Step into a realm where precision meets performance with our Cold Drawn Seamless Steel Pipes. Engineered with meticulous care, these pipes undergo a cold drawing process that enhances their structural integrity, surface finish, and dimensional accuracy. Ideal for applications requiring intricate details and high precision, these pipes offer a refined structure with improved mechanical properties. Experience the pinnacle of craftsmanship where every millimeter is a testament to perfection.

Special Shape Seamless Steel Pipe

Custom Contours for Unconventional Applications

Embrace the power of customization with our Special Shape Seamless Steel Pipes. Designed to break free from the conventional, these pipes cater to a myriad of innovative applications. Whether it's unique geometries for aerospace, intricate designs for automotive, or custom contours for machinery, our pipes are crafted to fit the unconventional. With a seamless construction that ensures uniform strength and resilience, these special shape pipes are not just unique in form but superior in performance.

Product Application

The Diverse Applications of Carbon Seamless Steel Pipes

Energy Exploration and Transmission

In the heart of the energy sector, our Carbon Seamless Steel Pipes are pivotal. From the depths of oil exploration to the heights of natural gas transmission, these pipes ensure a seamless flow, literally and

metaphorically. Their robust structure and resistance to high pressure make them indispensable in drilling operations, pipelines, and refineries, fueling the world's energy needs with unwavering reliability.

Automotive Excellence

Underpinning the automotive industry, our Carbon Seamless Steel Pipes drive innovation on the road. Known for their strength, precision, and durability, these pipes are integral to manufacturing high-performance engines, structural components, and exhaust systems. They not only withstand the rigors of the road but also contribute to the sleek aesthetics and safety of modern vehicles.

Construction and Infrastructure

As the skeleton of the construction and infrastructure sector, our pipes offer unparalleled support and stability. From towering skyscrapers to expansive bridges, our Carbon Seamless Steel Pipes provide a sturdy framework that stands the test of time and elements. Their ability to bear heavy loads and resist corrosive environments makes them the cornerstone of modern architecture and infrastructure.

Manufacturing and Machinery

In the realm of manufacturing and machinery, precision is paramount, and our Carbon Seamless Steel

Pipes deliver just that. Essential in the production of machinery parts, tools, and industrial equipment, these pipes ensure operational efficiency and longevity. Their high strength-to-weight ratio and adaptability make them the preferred choice for manufacturers aiming for excellence and innovation.

Heating and Plumbing

Our Carbon Seamless Steel Pipes play a critical role in heating and plumbing systems, ensuring comfort and functionality in residential, commercial, and industrial settings. Known for their ability to withstand high temperatures and pressures, these pipes are perfect for transporting water, steam, and gases, ensuring a seamless and efficient flow within systems.

Chemical and Process Industries

In the demanding environments of chemical and process industries, our pipes stand strong. Resistant to corrosive substances and extreme conditions, they are essential in the transportation of chemicals, fluids, and gases, maintaining integrity and safety in operations.

In every application, our Carbon Seamless Steel Pipes are not just components; they are enablers of progress and innovation. Embodying strength, precision, and versatility, they are the silent heroes in the relentless pursuit of industrial excellence. With HYT's Carbon Seamless Steel Pipes, industries don't just operate; they thrive.

Hot Searches