- Product Details

- {{item.text}}

Quick Details

-

Features:

-

automatic and stainless steel

-

Power:

-

27kw-110kw

-

Voltage:

-

380V

-

Weight (KG):

-

2500

-

Marketing Type:

-

New Product 2022

-

Warranty of core components:

-

2 Year

-

Product name:

-

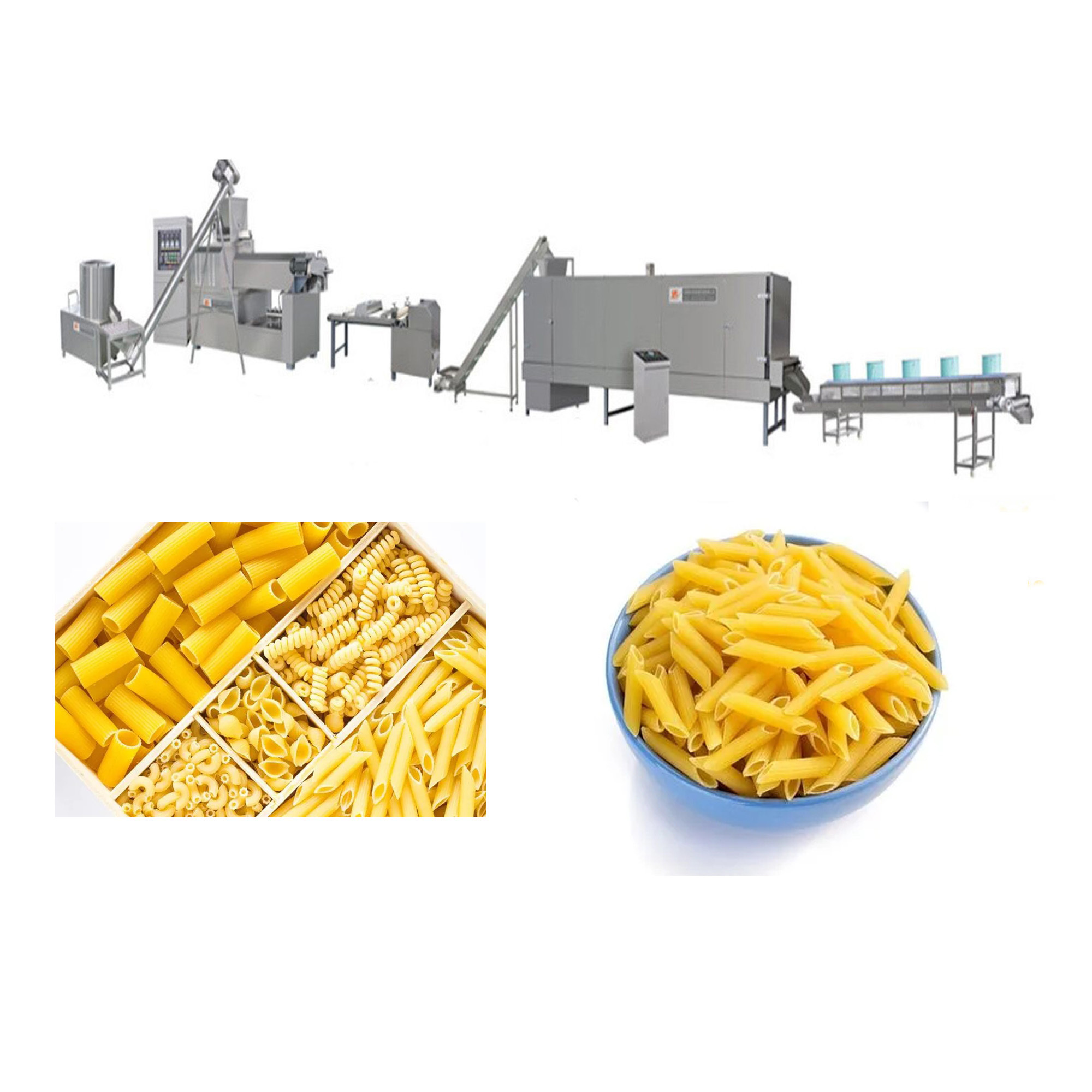

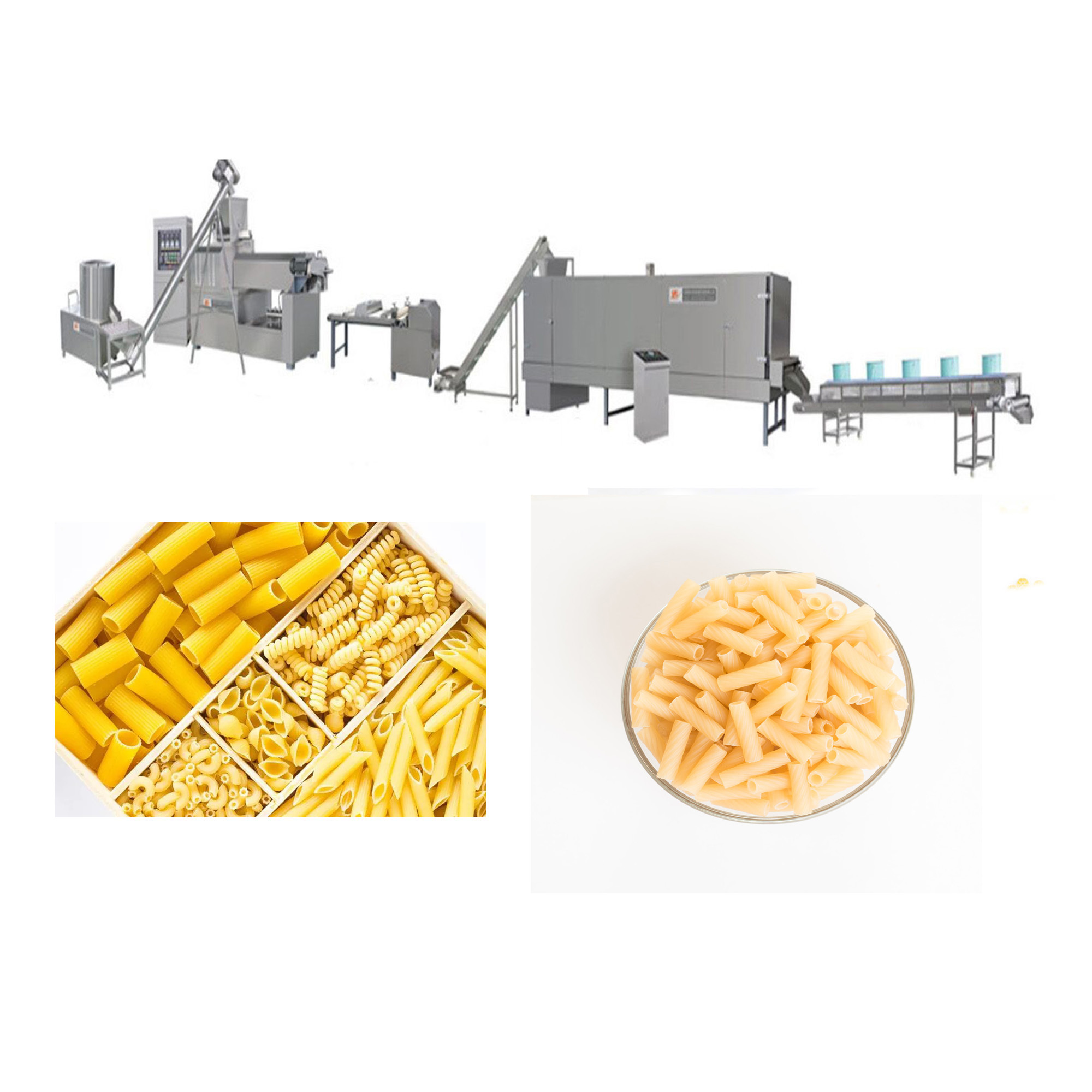

Fully automatic macaroni and pasta processing line

-

Motor:

-

Simens ABB

-

Capacity:

-

100-120kgh,250-300kgh and more

-

Type:

-

Fully Automatic

-

Machine Material:

-

Stainless Steal food grade

-

Energy:

-

Electricity Diesel Steam Gas

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Saibainuo

-

Application:

-

food factory/food shop/supermarket

-

Features:

-

automatic and stainless steel

-

Power:

-

27kw-110kw

-

Voltage:

-

380V

-

Weight (KG):

-

2500

-

Marketing Type:

-

New Product 2022

-

Warranty of core components:

-

2 Year

-

Product name:

-

Fully automatic macaroni and pasta processing line

-

Motor:

-

Simens ABB

-

Capacity:

-

100-120kgh,250-300kgh and more

-

Type:

-

Fully Automatic

-

Machine Material:

-

Stainless Steal food grade

-

Energy:

-

Electricity Diesel Steam Gas

Product Description

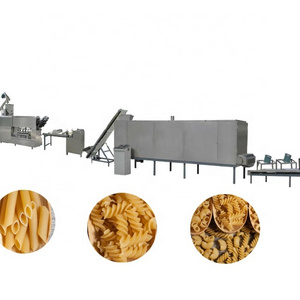

Fully-Automatic pasta and macaroni production line

Pasta is a traditional Italian cuisine, and gradually become the staple food all over theworld. Saibainuo offer complete pasta production lines for a wide range of typical short-cut pasta shapes. Process as below.

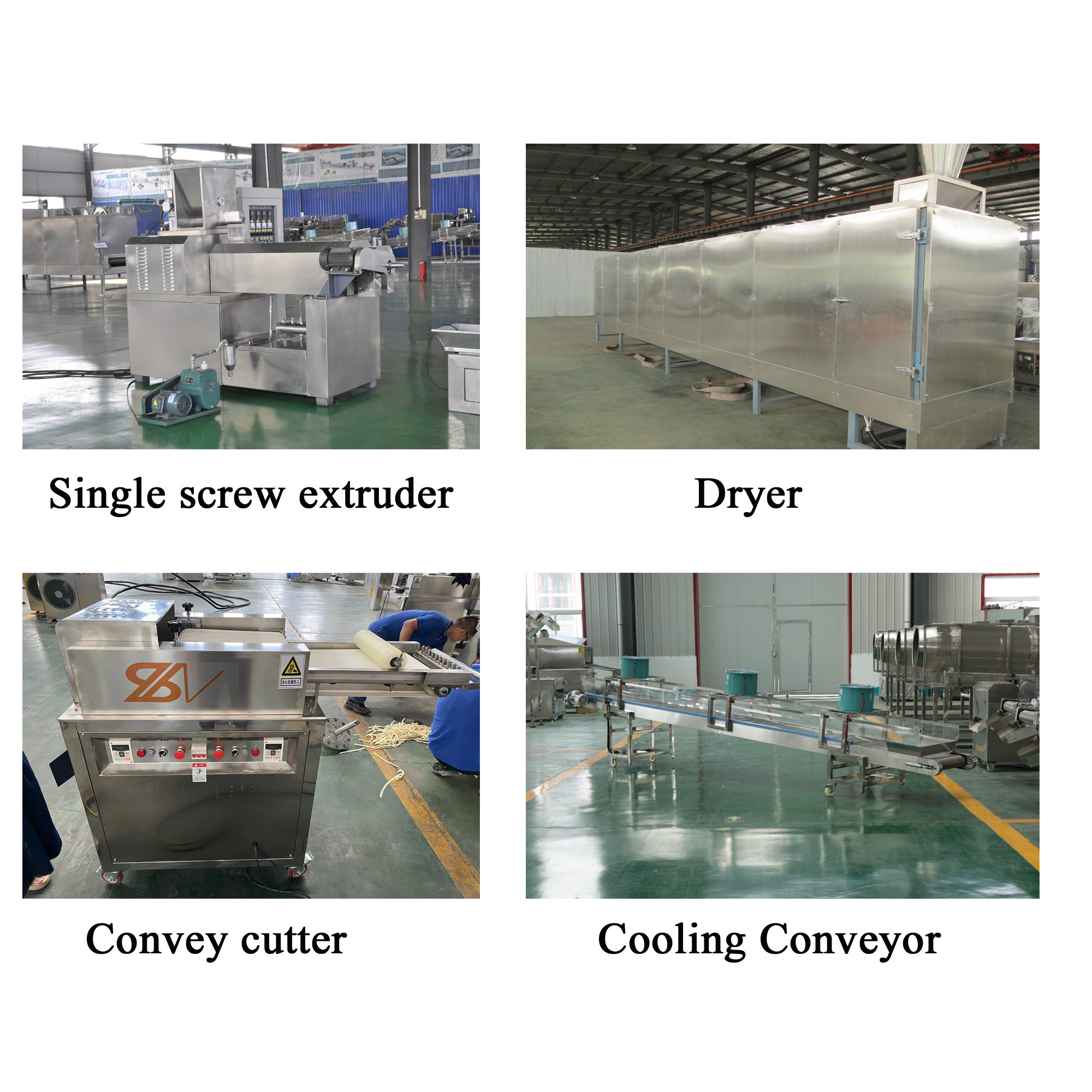

The raw material are mixed with precise ingredients and water. The extruding stage is carried out with a specially designed single-screw system to ensure optimal semolina mixing, compression and extrusion. Once the dough is kneaded to the requiredconsistency, it goes through fitted dies to produce the required shapes and cut to various length. After drying, the pasta iscooled and stabilized in the industrial pasta machine and then transported to storage or packaged directly.

The raw material are mixed with precise ingredients and water. The extruding stage is carried out with a specially designed single-screw system to ensure optimal semolina mixing, compression and extrusion. Once the dough is kneaded to the requiredconsistency, it goes through fitted dies to produce the required shapes and cut to various length. After drying, the pasta iscooled and stabilized in the industrial pasta machine and then transported to storage or packaged directly.

Detail of extruder.

1. The gearbox is made of SKF bearings and has a shelf life of 10 years. 2. The control system uses ABB

electrical components. 3.. 3 minutes cooking time to ensure pre-cooking effect. 4. Deep nitriding process guarantees the life of

the screw and barrel. 5.Straight cutting method to ensure smooth surface.

electrical components. 3.. 3 minutes cooking time to ensure pre-cooking effect. 4. Deep nitriding process guarantees the life of

the screw and barrel. 5.Straight cutting method to ensure smooth surface.

.

S

pecification

|

item

|

value

|

|

Place of Origin

|

China

|

|

|

Shandong

|

|

Brand Name

|

Saibainuo

|

|

Application

|

|

|

Features

|

|

|

Warranty

|

2 years

|

|

Dimension(L*W*H)

|

|

|

Power

|

27kw-110kw

|

|

Voltage

|

380V

|

|

Applicable Industries

|

Food & Beverage Factory, Restaurant, Home Use, Food Shop, Food & Beverage Shops, Other

|

|

Weight (KG)

|

2500

|

|

Showroom Location

|

Italy, Philippines, Pakistan, India, Russia, Thailand, South Africa, Kazakhstan, Nigeria, Australia

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Marketing Type

|

New Product 2022

|

|

Warranty of core components

|

2 Year

|

|

Core Components

|

Engine, Gearbox

|

|

Product name

|

Fully automatic macaroni and pasta processing line

|

|

Motor

|

Simens ABB

|

|

Capacity

|

100-120kgh,250-300kgh and more

|

|

Type

|

Fully Automatic

|

|

Machine Material

|

Stainless Steal food grade

|

|

Energy

|

Electricity Diesel Steam Gas

|

Hot Searches