- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

SHUNFENG

-

Model Number:

-

GZDFR400*2

-

Voltage:

-

220V 60Hz

-

Dimension(L*W*H):

-

5.6*1.55*1.9m

-

Weight:

-

2300kg

-

Warranty:

-

1.5 years

-

Certification:

-

CE ISO SGS

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Function:

-

Making T-shirt bag

-

Machine type:

-

heat sealing heat cutting

-

Capacity:

-

220pcs/min

-

Max Bag Width:

-

370mm*2

-

Max Bag Length:

-

300-999mm

-

Max Feeding Diameter:

-

800mm

-

Producing Speed:

-

150-220pcs*2/min

-

Film Thickness:

-

0.01-0.035mm

-

Main Motor(KW):

-

1.5

Quick Details

-

Machine Type:

-

SEALING MACHINE

-

Bag Type:

-

T-shirt Bag

-

Material:

-

Plastic

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

SHUNFENG

-

Model Number:

-

GZDFR400*2

-

Voltage:

-

220V 60Hz

-

Dimension(L*W*H):

-

5.6*1.55*1.9m

-

Weight:

-

2300kg

-

Warranty:

-

1.5 years

-

Certification:

-

CE ISO SGS

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Function:

-

Making T-shirt bag

-

Machine type:

-

heat sealing heat cutting

-

Capacity:

-

220pcs/min

-

Max Bag Width:

-

370mm*2

-

Max Bag Length:

-

300-999mm

-

Max Feeding Diameter:

-

800mm

-

Producing Speed:

-

150-220pcs*2/min

-

Film Thickness:

-

0.01-0.035mm

-

Main Motor(KW):

-

1.5

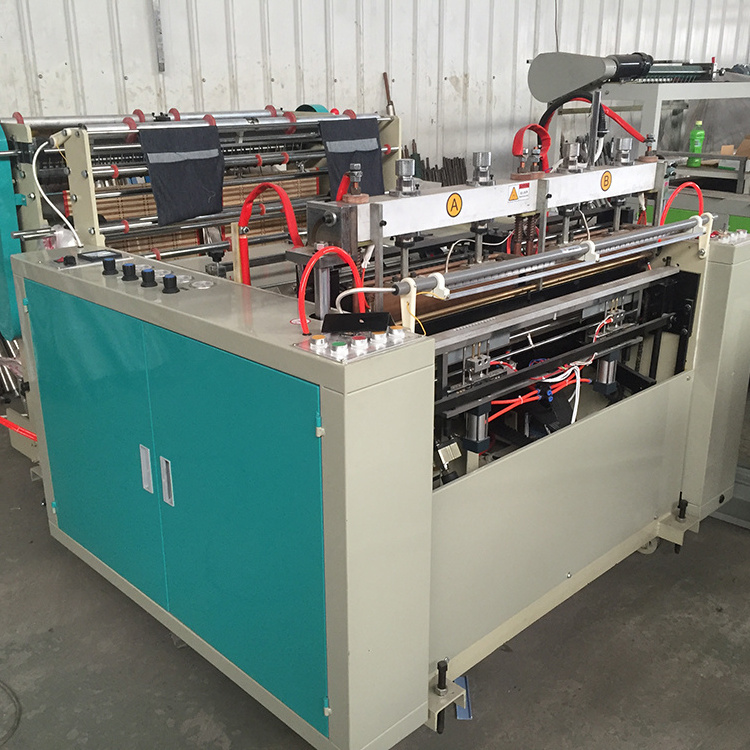

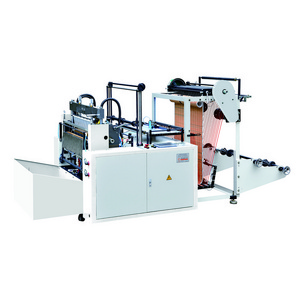

High speed heat cutting biodegradable plastic t-shirt bag making machine

Main Technical Description

Usage and features:

It is suitable for hot sealing and cutting printed or not printed HDPE LDPE plastic film.

Performance and allocations:

1.Especially designed for hot sealing and cutting of T-shirt bag.It can be punched automatically in two production line which will increase the production and save the worker

2.Photocell for accurate registration of film printing points if the photocell can`t catch printing point,The machine will stop automatically

3.Invertor control speed,easy operation,reduce electric consumption

4.Automatic stopping when run out of film

5.Strong sealing and output bags being tear up neatly

6.Punching machine used air and liquid pressurized cylinder,so the noise is low and the gas consumption is little.

Main Technical Parameters:

|

Model |

GZDFR400*2 |

GZDFR500*2 |

|

Max Bag Width |

370mm*2 |

470mm*2 |

|

Max Bag Length |

300-999mm |

300-999mm |

|

Max Feeding Diameter |

800mm |

800mm |

|

Producing Speed |

150-220pcs*2/min |

150-220pcs*2/min |

|

Film Thickness |

0.01-0.035mm |

0.01-0.035mm |

|

Main Motor(KW) |

1.5KW |

1.7KW |

|

Main Power(KW) |

9KW |

9KW |

|

Machine weight |

2300KG |

2400KG |

|

Machine size(L*W*H) |

5600*1550*1900mm |

5600*1650*1900mm |

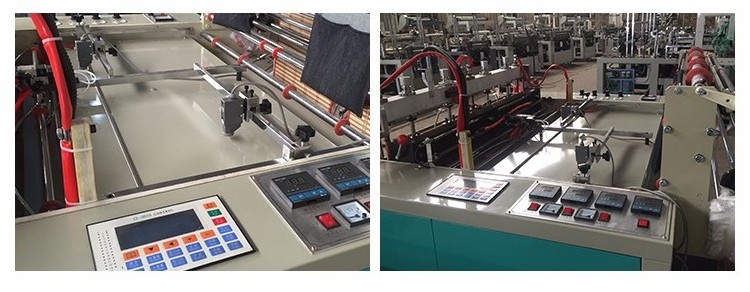

Main Parts:

|

Parts Name |

From |

|

Main Motor |

SHANGHAI |

|

Servo Motor |

CHINA |

|

Computer |

TAIWAN |

|

Transformer |

CHINA |

Configuration:

|

Temperature meter |

Omron |

|

Switch |

Schneider |

|

Inverter |

Delta |

|

Relay |

Omron |

|

Solenoid valve |

Taiwan |

|

Thermocouple |

RKC JAPAN |

|

Voltmeter |

Japan |

|

Ammeter |

Japan |

|

Power |

2PASE 220V 60HZ |

Zhejiang Lifeng Machinery Co., Ltd,which has a long history, grand scale, self-research, sales service is professionally manufacturing plastic soft packaging machine with high technology.The quality of its products had firstly passed the certification of quality management system ISO9001-2008 and CE certification of European Union.

We are professional manufacture in kinds of Bag Making Machine,Film Blowing Machine,Printing Machine,Cutting Machine ,Recycle Machine,Plastic Air Bubble Film Machine,Laminating Machine,Slitting and Rewinding Machine are popular in all the markets of the whole world ,products are exported to eastern Europe,North America ,Southeast,Asia,Russia,Africa,Middle East and more than 20 countries and regions , They win good reaction in the market and welcomed by vast customers no matter new or old from home and abroad.

Q1:Are you a factory or trading company?

A1

:

We are established in 1995, a actual factory and manufacturer in the line of printing&package machine for 20 years.

Q2:Where is your factory located? How can I visit there?

A2

:

Our factory is located in Rui'an City, Zhejiang Province, China, about one hour by air from Shanghai. All our clients, from home or abroad, are warmly welcome to visit us!

Q3: Which industries are widely used in of your machine?

A3

:

Those are mainly used in making plastic bags and labels in the maket. Examples of stand up pouch, zipper pouch, plastic bag for dialy necessities and food, plastic label for drink bottle, Foil yogurt cup, Medical pouch, laminated film or soft carboard, etc.

Q4: How about the payment term?

A4

:

For new customer, our payment terms is 30% T/T in advance before production, the balance 70% should be paid before delivery.

Q5: What about your main market?

A5

:

Ourproducts be sold well in 30 provinces and have good reputation in China, also we pay attention on developing the overseas market, such as Europe, Russia, Southeast Asia, Middle and South America, Africa, and other countries.

Q6: How does your factory do regarding quality control?

A6

:

Quality is the most important principle. GREAT WALL people always attach great importance to quality controlling from the very beginning to the very end. Our factory has passed ISO and CE certification.

Q7:What about warranty and do the engineers available to overseas?

A7

:

One year warranty. During this period, if the machine has some problems, our engineers can go abroad to fix for you.

Q8:What about the service after sale?

A8

:

One you have bought our machine, you can call us or email us telling us the machine problems and any questions about the machines. We will reply to you with 12hours and help you to slove the problem.