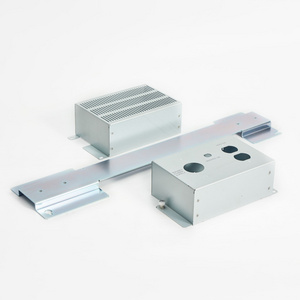

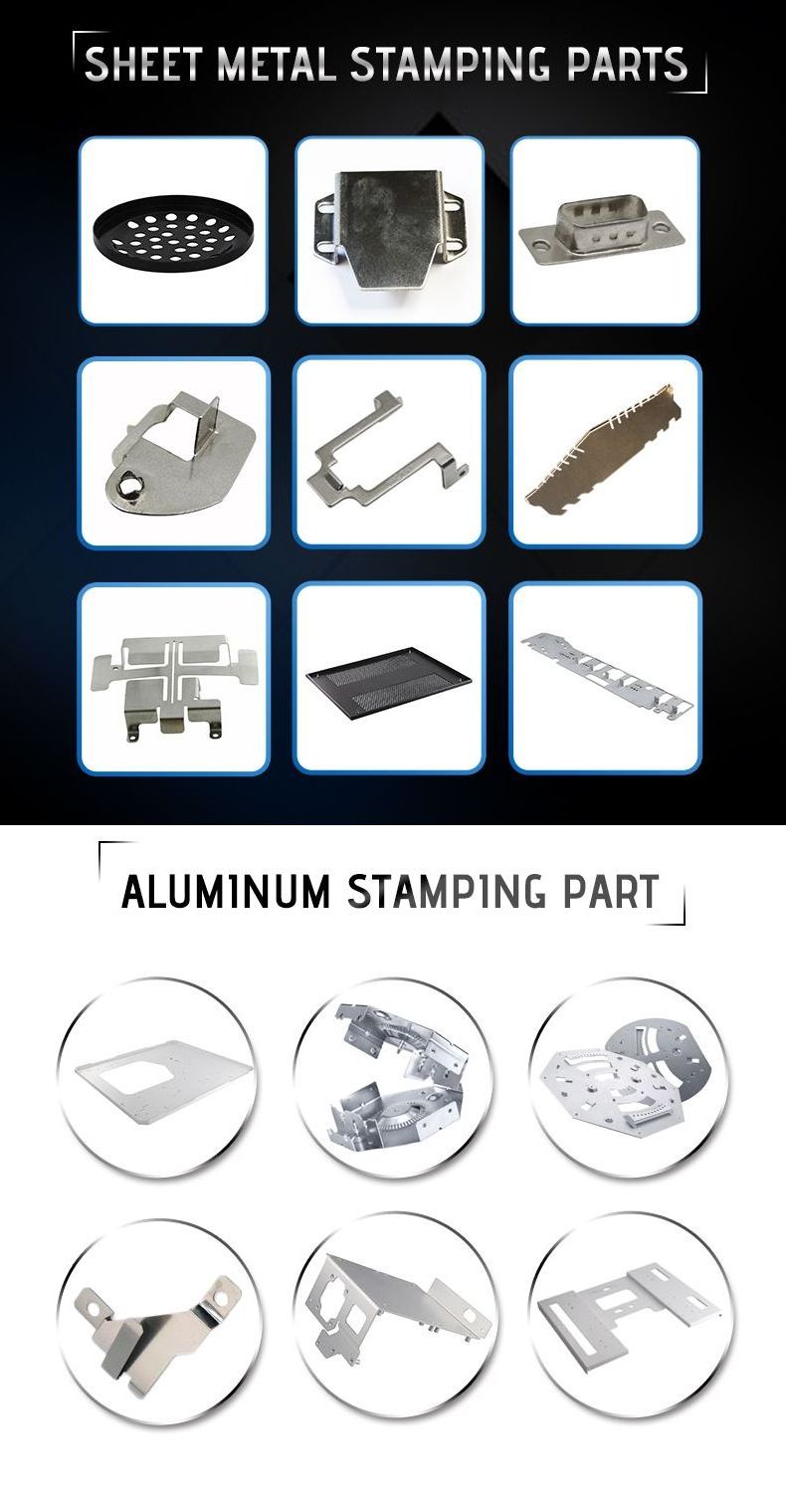

2. Versatility:

Our stamping is a versatile production process that can be used to create a wide range of parts and products with different shapes, sizes, and thicknesses.

3. Speed and consistency:

Our stamping can produce high-quality parts at a fast rate, which makes it an ideal production method for businesses that need to meet tight deadlines. It also offers consistent results, ensuring that every part produced is identical in size, shape, and quality, which is crucial for ensuring product reliability and consistency.