- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HY

-

Weight:

-

120 kg

-

Marketing Type:

-

New Product 2023

-

material:

-

stainless steel

-

material quality:

-

alloy stainless

-

HRC:

-

53*56

Quick Details

-

Max. Capacity:

-

10 ton/h

-

Applicable Industries:

-

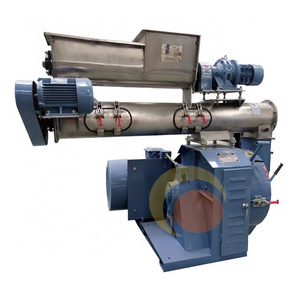

pellet mill, pellet processing ,machine, wood pellet machine, feed processing machine

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HY

-

Weight:

-

120 kg

-

Marketing Type:

-

New Product 2023

-

material:

-

stainless steel

-

material quality:

-

alloy stainless

-

HRC:

-

53*56

Products Description

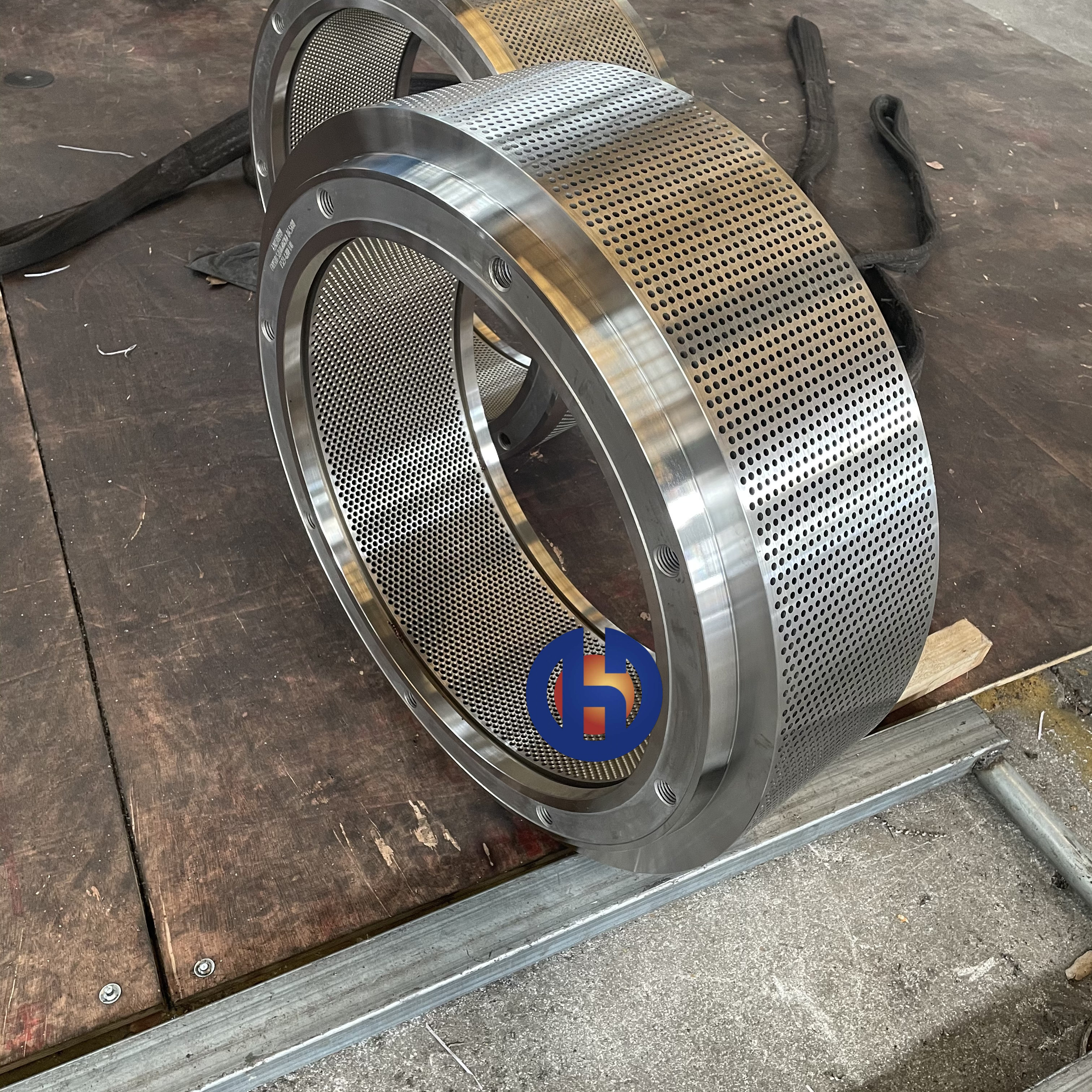

About the customization all pellet machine parts of Buhler Group

ring dies

.

Features:

1. Select high-quality refining and degassing blank outside the furnace

2. The die adopts imported gun drilling and multi-station group drilling, the die hole is formed at one time, the finish is

high, the production feed appearance is beautiful, the output is high, the discharge is smooth, and the granules are well formed

3. The die adopts the combined treatment process of the American vacuum furnace and the continuous quenching furnace, which is quenched uniformly, the surface finish is good, the hardness is high, and the service life is doubled.

2. The die adopts imported gun drilling and multi-station group drilling, the die hole is formed at one time, the finish is

high, the production feed appearance is beautiful, the output is high, the discharge is smooth, and the granules are well formed

3. The die adopts the combined treatment process of the American vacuum furnace and the continuous quenching furnace, which is quenched uniformly, the surface finish is good, the hardness is high, and the service life is doubled.

|

Material

|

Hardness

|

Diameter

|

Outer diameter

|

Level

|

Certification

|

|

X46Cr13(stainless steel)

|

HRC52-55

|

0.8mm-28mm

|

<1800mm

|

1

|

CE/IOS

|

|

20CrMnTi(Alloy Steel)

|

HRC60-62

|

1.0mm-28mm

|

<1800mm

|

1

|

CE/IOS

|

Our ring dies are suitable for:

1. Biomass pellet machine: wood pellet machine, sawdust pellet machine, grass pellet machine, straw pellet machine, crop straw

pellet machine, alfalfa pellet machine, etc.

2. Livestock and poultry feed pellet machine: pig/cattle/sheep/chicken/duck/rabbit/snail/bird

3. Cat litter pellet

4. organic compound fertilizer

5. Aquatic feed:Fish and Shrimp

pellet machine, alfalfa pellet machine, etc.

2. Livestock and poultry feed pellet machine: pig/cattle/sheep/chicken/duck/rabbit/snail/bird

3. Cat litter pellet

4. organic compound fertilizer

5. Aquatic feed:Fish and Shrimp

6.Activated carbon granules

Manufacturing Technique

Customizable

If you are not satisfied with pellet

please contact us assist you in adjusting the compression ratio.

We have 20+ years of experience in ring die manufacturing , familiar with the compression ratio each type of pellet, helping you improve particle quality and yield,

We calculate the appropriate opening rate for different materials ensure the maximum use of the ring die,

especially the cat litter ring die, which will not crack

Customers without drawings

Please contact our customer service and we will provide you with a solution

Our small aperture ring die :

has no blind holes or broken drills,

and the interior is smooth and beautiful

and the interior is smooth and beautiful

Mold split

The wrong opening ratio will cause the ring die to burst. Different animal feed pellets have different opening ratios, which need to be adjusted according to the situation.

Incorrect compression ratio

Improper compression ratio,

Easy to produce long and short materials, thick and fine materials

Incorrect opening rate

This is the wrong opening ratio

Low compression ratio

The compression ratio is too low, resulting in particles not forming and cracks on the surface of the particles

High compression ratio

Excessive compression ratio, high particle hardness, blackening of particles, and carbonization phenomenon

Correct parameters

Correct compression ratio, similar particle length, smooth surface without cracks, and smooth discharge

Select high-quality stainless steel X46Cr13 material, and refuse to use other inferior materials

Can provide forging material quality inspection report

Increase the level of release holes

Increase ring die thickness

Facilitate discharge and prevent breakage

Adjust the size of the feed port according to the customer's situation

i=d/L

T=L+M

M is the depth of the reduced hole

The Compression ratio (i) is the ratio of die hole diameter (d) and effective length (L) of the die.

T=L+M

M is the depth of the reduced hole

The Compression ratio (i) is the ratio of die hole diameter (d) and effective length (L) of the die.

According to nature of raw material, The user chooses the compression ratio of the die, and adjusts the

specific compression ratio, such as selecting a slightly lower compression ratio, which is beneficial to increase the output,

reduce the energy consumption, reduce the wear of the ring mold, but also reduce the quality of the particles, such as the pellets

is not strong enough, the appearance is loose and the length is different, and the powder rate is high.

specific compression ratio, such as selecting a slightly lower compression ratio, which is beneficial to increase the output,

reduce the energy consumption, reduce the wear of the ring mold, but also reduce the quality of the particles, such as the pellets

is not strong enough, the appearance is loose and the length is different, and the powder rate is high.

Hot Searches