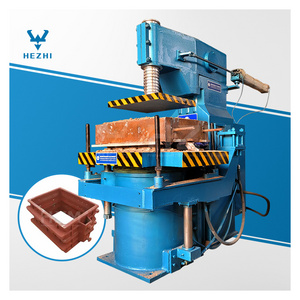

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customized

-

Power:

-

customized

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

800

-

Color:

-

Customized Color

-

Usage:

-

Casting

-

Package:

-

Seaworthy wood cases

-

Delivery time:

-

7 days

-

Spare parts service:

-

Lifetime

-

Test before delivery:

-

Yes

-

Warranty time:

-

One year

-

OEM:

-

Yes

-

Sand Type:

-

Clay sand

-

Fuel:

-

Electric

Quick Details

-

Place of Origin:

-

Qingdao, China

-

Machine Type:

-

Foundry Machine

-

Brand Name:

-

JinRun

-

Voltage:

-

Customized

-

Power:

-

customized

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

800

-

Color:

-

Customized Color

-

Usage:

-

Casting

-

Package:

-

Seaworthy wood cases

-

Delivery time:

-

7 days

-

Spare parts service:

-

Lifetime

-

Test before delivery:

-

Yes

-

Warranty time:

-

One year

-

OEM:

-

Yes

-

Sand Type:

-

Clay sand

-

Fuel:

-

Electric

Features:

Optimal design of aircraft structures, the machine using the fuselage box structure basket to improve the body rigidity.

It adopts microseism squeeze molding technics to significantly increase the pressure and the strength to make up hardness HB90 sandbox more than one level to increase surface roughness, make the quality of the other products stable.

Shock part of it with a buffer spring,effectively reduce the impact of machine-to-base.

The machine adopt cylinder, crank, connecting rod, synchronizing saft achieve molding synchronously.

Control part, all pneumatic components used to achieve the overall functionality,simple operation,easy maintenance.

Parameter:

| Model | Flask Max. Size (mm) | Worktable Diamension | Jolting load (kgf) | Compress Stress (kgf) | Compress Process (mm) | Moulding Process(mm) | Productivity (Flasks/h) |

| Z145WA | 500*450*200 | 600*550 | 3300 | 5500 | 200 | 180 | 40-60 |

| Z145WB | 500*450*200 | 600*500 | 300 | 6300 | 200 | 200 | 40-60 |

| Z146W | 600*500*250 | 700*550 | 400 | 7500 | 200 | 220 | 40-60 |

| Z148W | 800*600 | 900*730 | 600 | 10000 | 200 | 250 | 40-60 |