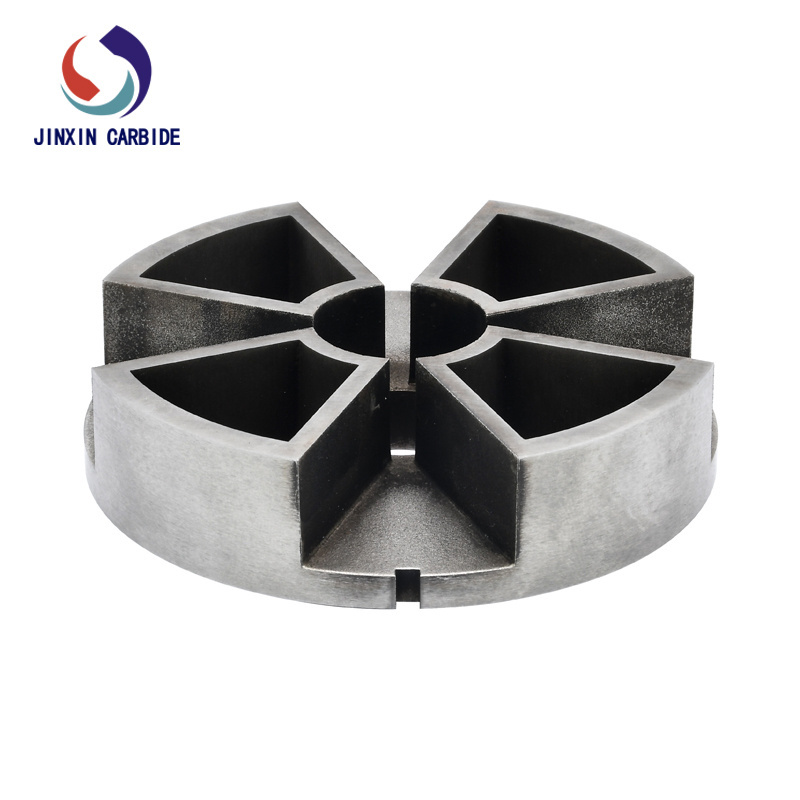

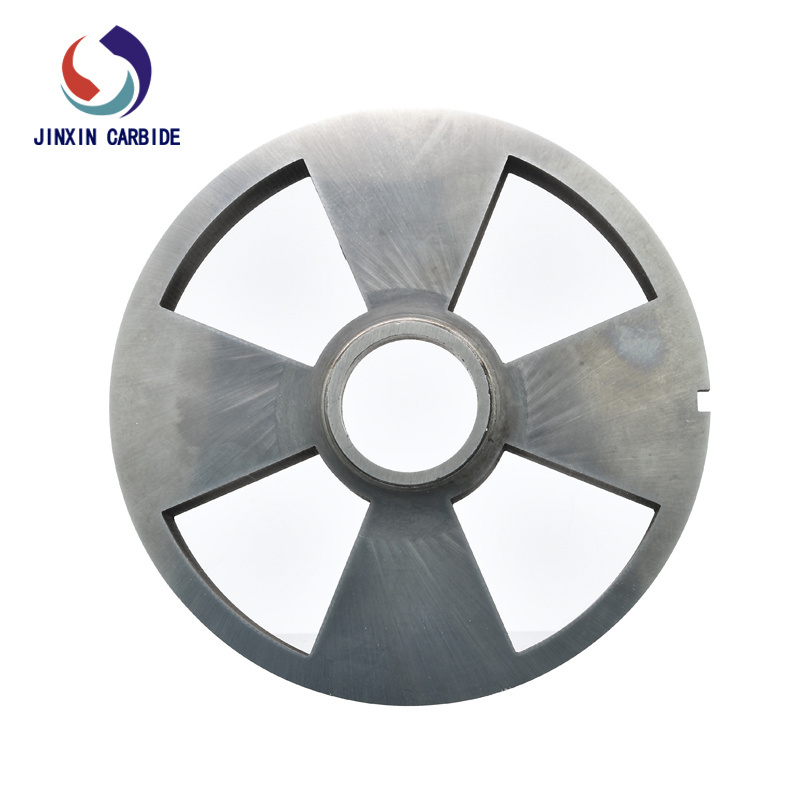

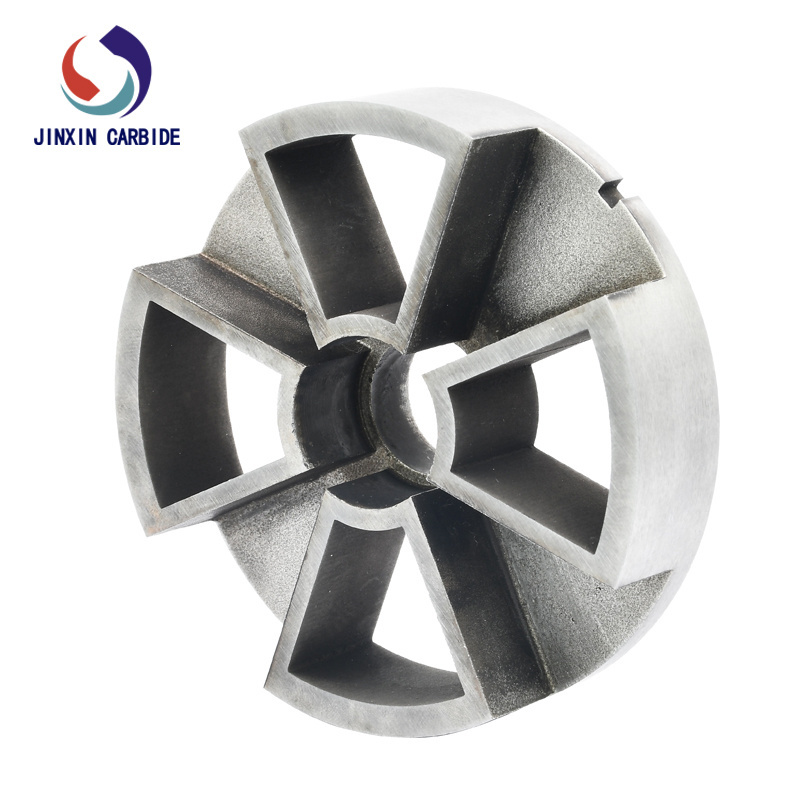

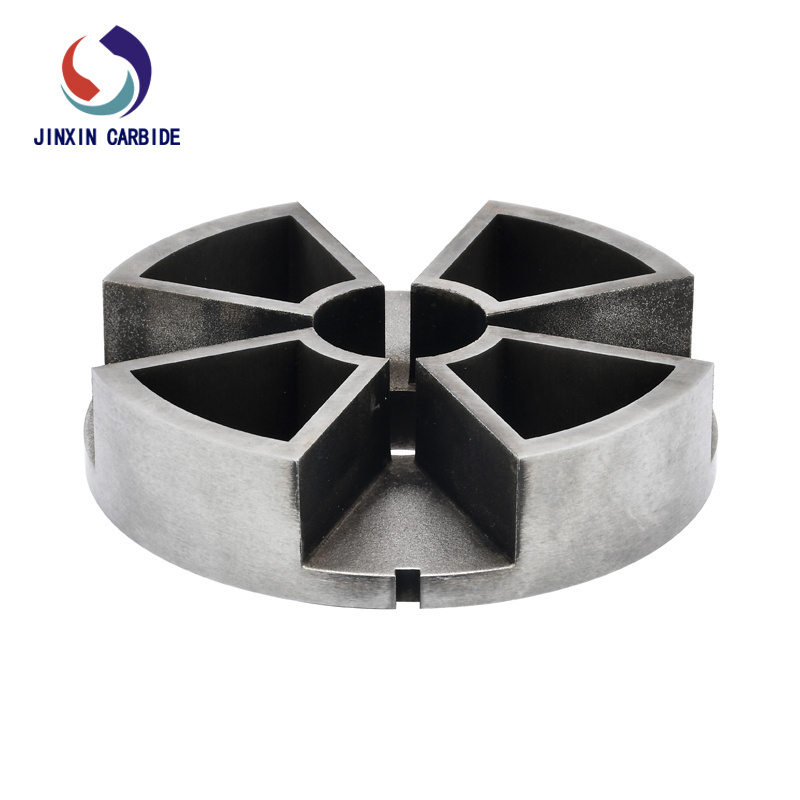

Tungsten carbide stator for APS advanced MWD systems used in rotary pulser Tungsten Carbide Rotor and Stator Mwd Oil and Gas

Industry China manufacture bushing of tungsten carbide from manufacturer bushing of tungsten carbideSome Details of our bushing of

tungsten carbide from manufacturerfor Reference

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

JX

-

Particle:

-

0.2-0.4um

-

Product name:

-

YG8 Tungsten Carbide Rotors Tool Part For Off Shore Rig

-

Material:

-

WC+Ni/WC+Co

-

Grade:

-

YG11 YG8

-

Feature:

-

Wear Resistance, Corrosion Resistance,High Precision, long lifetime

-

Hardness:

-

HRA89-90 Bending strength:3500

-

Surface finishing:

-

Ra0.2-0.4

-

Straightness:

-

0.005

-

Technology:

-

HIP sintering

-

ISO code grade:

-

ISO9001:2015

-

Delivery:

-

5-15Days

Quick Details

-

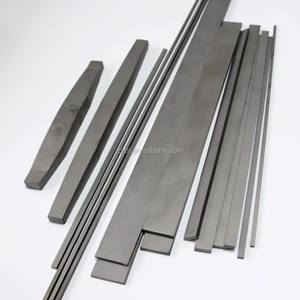

Alloy Specification:

-

YG8,YG11,YG15,YS2T,YL10.2

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

JinXin

-

Model Number:

-

JX

-

Particle:

-

0.2-0.4um

-

Product name:

-

YG8 Tungsten Carbide Rotors Tool Part For Off Shore Rig

-

Material:

-

WC+Ni/WC+Co

-

Grade:

-

YG11 YG8

-

Feature:

-

Wear Resistance, Corrosion Resistance,High Precision, long lifetime

-

Hardness:

-

HRA89-90 Bending strength:3500

-

Surface finishing:

-

Ra0.2-0.4

-

Straightness:

-

0.005

-

Technology:

-

HIP sintering

-

ISO code grade:

-

ISO9001:2015

-

Delivery:

-

5-15Days

Product Description

New Stock Of Hot-selling PLC Inverter YG8 Tungsten Carbide Rotors Tool Part For Off Shore Rig

Specification

1) 100% virgin raw material

2) Customized,We have over 15 years' experience in the shaped tungsten carbide products

3) Various kinds of material grades are available based on customer's application

4) we have professional advanced production line and inspection equipment to ensure high quality products.

5) Advanced technology with precision ground and high polishing process

6) High wear resistance, high hardness and impact toughness

7) Excellent after-sales service

2) Customized,We have over 15 years' experience in the shaped tungsten carbide products

3) Various kinds of material grades are available based on customer's application

4) we have professional advanced production line and inspection equipment to ensure high quality products.

5) Advanced technology with precision ground and high polishing process

6) High wear resistance, high hardness and impact toughness

7) Excellent after-sales service

1.Made by 100% original tungsten carbide material

2.High abrasive resistance

3.After accurate grinding and polishing,the frictional factor of surface is very low.

4.Widely used in ball-bearing,seat valve, ball screws and flow meters.pen,spraying machines ,pump,machinery parts,oil,hydrochloric

zcid lab,hardness measuring instrument,and so high-end industry.

5.Recommended grade: YG8,YG11,YG15,YS2T,YL10.2,other grade can be offered by customers' request.

6.We can manufacture various tungsten carbide valve seat in high qulaity with competitive price.

2.High abrasive resistance

3.After accurate grinding and polishing,the frictional factor of surface is very low.

4.Widely used in ball-bearing,seat valve, ball screws and flow meters.pen,spraying machines ,pump,machinery parts,oil,hydrochloric

zcid lab,hardness measuring instrument,and so high-end industry.

5.Recommended grade: YG8,YG11,YG15,YS2T,YL10.2,other grade can be offered by customers' request.

6.We can manufacture various tungsten carbide valve seat in high qulaity with competitive price.

Hot Searches