- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

0.01

-

CrO Content (%):

-

0.1~0.3%

-

SiC Content (%):

-

1.2-1.4

-

Place of Origin:

-

Henan, China

-

Model Number:

-

Customer's Requirement

-

Brand Name:

-

Sijihuo

-

Application:

-

Industrial Furnaces

-

Color:

-

Pure White

-

BULK DENSITY:

-

64/96/128/160kg/m3

-

Raw material:

-

Aluminosilicate

-

Working temperature:

-

1260-1430C

-

Certificate:

-

ISO9001

-

Length(mm):

-

3650-14000

-

Width(mm):

-

610,1220

-

Thickness(mm):

-

6-50

-

Type:

-

Ceramic Raw Materials

Quick Details

-

SiO2 Content (%):

-

50%~65%

-

Al2O3 Content (%):

-

38-42%

-

MgO Content (%):

-

0.8-1.2

-

CaO Content (%):

-

0.01

-

CrO Content (%):

-

0.1~0.3%

-

SiC Content (%):

-

1.2-1.4

-

Place of Origin:

-

Henan, China

-

Model Number:

-

Customer's Requirement

-

Brand Name:

-

Sijihuo

-

Application:

-

Industrial Furnaces

-

Color:

-

Pure White

-

BULK DENSITY:

-

64/96/128/160kg/m3

-

Raw material:

-

Aluminosilicate

-

Working temperature:

-

1260-1430C

-

Certificate:

-

ISO9001

-

Length(mm):

-

3650-14000

-

Width(mm):

-

610,1220

-

Thickness(mm):

-

6-50

-

Type:

-

Ceramic Raw Materials

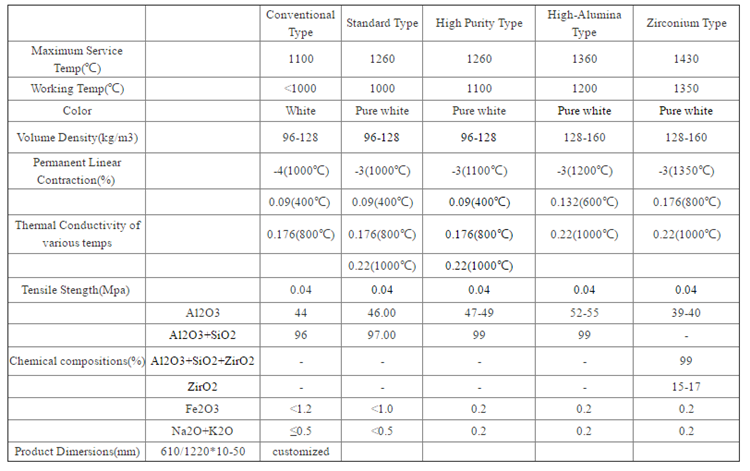

2018 Ceramic Fiber Wool Insulation Blanket

All kinds of aluminum silicate fiber blanket, made from common, high pure, zircona, chromic aluminum silicate fiber, after the process of needling, thermoforming, crossbar cutting, rolling up ,etc. which is through double-sided needling operation by using spun technology. All kinds of needling blanket not only have the same excellent function of corresponding aluminum silicate fiber, but also have low shrink and high tearing strength. In addition, the blanket own even texture and integrity surface.

CT spun fib er blanket adopt high pure raw materials without any binding agent, ensure the product own good reliability and stability in any environment. the function of the blanket isn’t affected by water and oil, it will recover its thermal performance and physical property after drying.

Needling blanket in different size and thickness provide users a wide range of material selection to gain the best heat insulation structure and energy saving effect.

Application:

1) Cement and other building materials industry kiln back insulation;

2) Petrochemical, metallurgical, ceramics, glass industry, the furnace lining insulation;

3)Heat treatment furnace backlash insulation;

4)Non-ferrous metal industry back insulation;

5)High temperature reaction, heating equipment back insulation insulation