- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

350bag/min

-

Weight (KG):

-

750

-

Voltage:

-

220V/380V/50Hz

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Skywin

-

Dimension(L*W*H):

-

8600*1000*950MM

-

Speed:

-

50-300 Bag/min

-

Capacity:

-

20000-25000PCS/H

-

Material:

-

304 Stainless Steel

-

Motor:

-

Three servo motor

-

Bag lengh:

-

80-500mm

-

Bag width:

-

60-160mm

-

Product height:

-

5-45mm

-

Film width:

-

80-370mm

-

Packing film material:

-

OPP.PE.PVC.OPP.CPP.PTPE.KOP.Aluminum Film

-

After-sales Service Provided:

-

Video technical support, Online support

-

Marketing Type:

-

New Product 2022

Quick Details

-

Function:

-

FILLING, Wrapping, Labeling, Laminating, Sealing, SLITTING, counting

-

Packaging Type:

-

Stand-up Pouch, Bags, Film

-

Packaging Material:

-

Plastic, aluminium film

-

Production Capacity:

-

350bag/min

-

Weight (KG):

-

750

-

Voltage:

-

220V/380V/50Hz

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Skywin

-

Dimension(L*W*H):

-

8600*1000*950MM

-

Speed:

-

50-300 Bag/min

-

Capacity:

-

20000-25000PCS/H

-

Material:

-

304 Stainless Steel

-

Motor:

-

Three servo motor

-

Bag lengh:

-

80-500mm

-

Bag width:

-

60-160mm

-

Product height:

-

5-45mm

-

Film width:

-

80-370mm

-

Packing film material:

-

OPP.PE.PVC.OPP.CPP.PTPE.KOP.Aluminum Film

-

After-sales Service Provided:

-

Video technical support, Online support

-

Marketing Type:

-

New Product 2022

Product Description

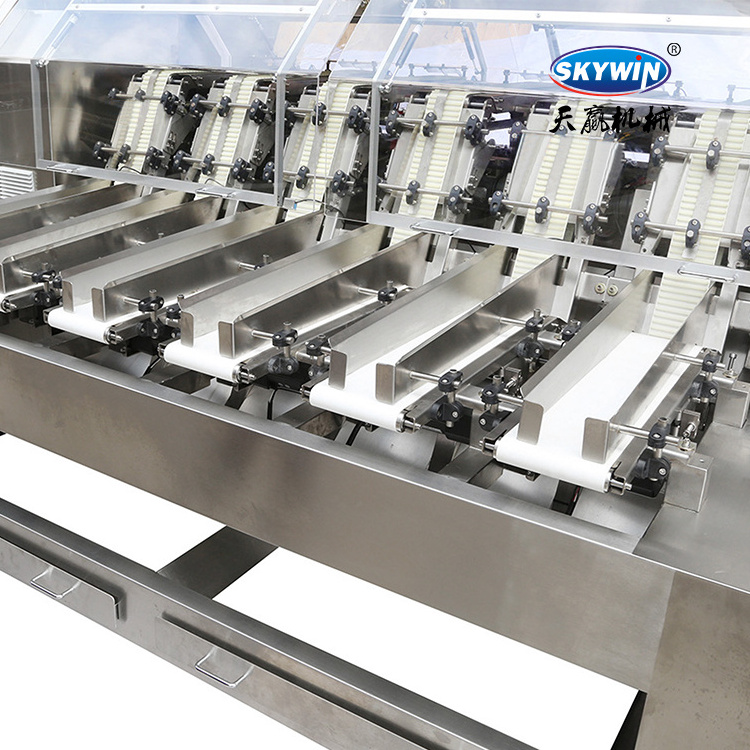

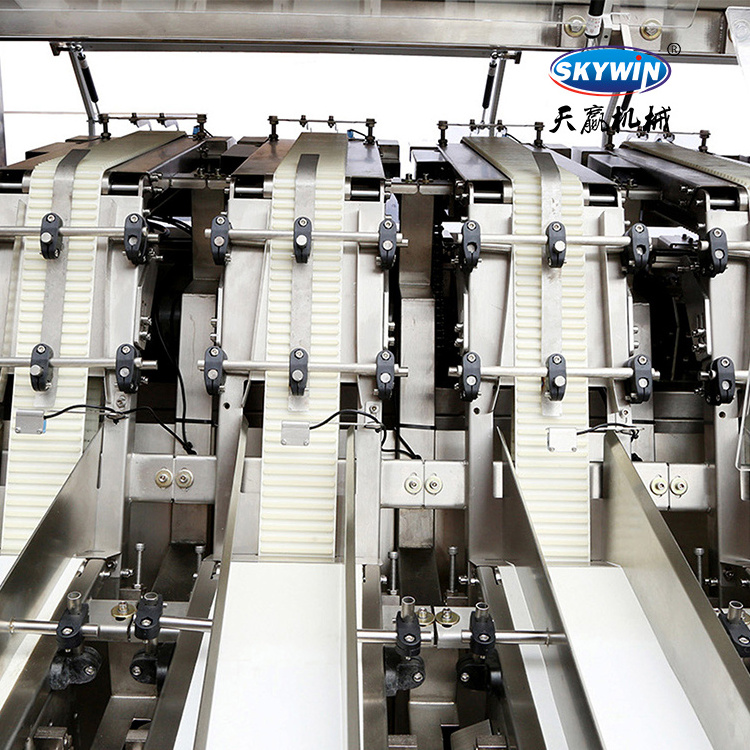

Automatic Stick Biscuits Counting and Packing Line

This packaging line is suitable for regular strip products, such as finger biscuits, Pretz, Pocky, egg rolls, sausages and other regular strip packaging, counting, wrapping and boxing. The more strips per package, the more time it takes to count, and the slower the packaging speed.

Feature

1. packing line is mainly composed of sorting and conveying unit, steering unit, automatic feeding unit, laminated conveyor unit and packaging unit.

2.The process of sorting, conveying, feeding and packaging are fully automated, without manual operation

3.Customer can not only dump products on feeding belt by manual, but also connect with the production line Work in coordination, Speed change, automatic stop/start in case of material absence/supply and other intelligent control.

4. PLC and servo control. touch screen display, packaging process visualization. Work stable, simple and convenient operation.

5.Simple structure,easy for cleaning,convenient maintenance.

1. packing line is mainly composed of sorting and conveying unit, steering unit, automatic feeding unit, laminated conveyor unit and packaging unit.

2.The process of sorting, conveying, feeding and packaging are fully automated, without manual operation

3.Customer can not only dump products on feeding belt by manual, but also connect with the production line Work in coordination, Speed change, automatic stop/start in case of material absence/supply and other intelligent control.

4. PLC and servo control. touch screen display, packaging process visualization. Work stable, simple and convenient operation.

5.Simple structure,easy for cleaning,convenient maintenance.

Auto loader

Specification

|

Machine

|

Auto Stick Counting Machine + Plow Packing Machine

|

|

Packing Speed

|

50-300bag/min

(The more strips per pack, the longer the counting time and the slower the packing speed.)

|

|

Control

|

PLC control system

|

|

Packing Type

|

Pillow packaging/ Flow packaging

|

|

Bag Length

|

80-500mm

|

|

Bag Width

|

60-160mm

|

|

Product Height

|

5-45mm

|

|

Film width

|

80-370mm

|

|

Packing film thickness

|

0.04-0.07mm

|

|

Power consumption

|

3.6KW

|

|

Film material

|

OPP/PE,PVC,OPP/CPP,PT/PE/KOP/CP,Aluminum film

|

|

Optional Device

|

Date Coder / Air-filing Device / Punching Device and etc.

|

Packing Sample

1. Auto counting--flow pack--box package (for option), full automatic.

2.Tray separating--auto counting--flow pack, full automatic.

2.Tray separating--auto counting--flow pack, full automatic.

Pakcing & Delivery

Step 1: Mechanical surface coated with preservative solution (to protect stainless steel).

Step 2: The plastic cushion packing machine (prevent bump).

Step 3: Plastic film packaging (to prevent ventilation).

Step 4: Wooden case / frame packaging (easy to transport).

Step 5: Tie the bandage outside of the wooden case (reinforcement overall).

Step 2: The plastic cushion packing machine (prevent bump).

Step 3: Plastic film packaging (to prevent ventilation).

Step 4: Wooden case / frame packaging (easy to transport).

Step 5: Tie the bandage outside of the wooden case (reinforcement overall).

Hot Searches