- Product Details

- {{item.text}}

Quick Details

-

Formaldehyde Emission Standards:

-

E1

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HAISEN

-

Model Number:

-

1220*2440

-

Product name:

-

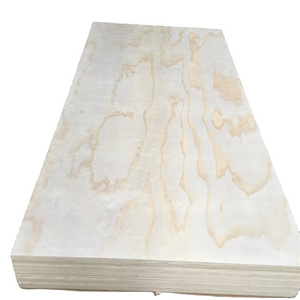

CDX Pine Plywood

-

Core:

-

Poplar,Pine ,Hardwood, Combi,Eucalyptus

-

Face/back:

-

Pine VNEEER

-

Glue:

-

E0/E1/E2/MR/WBP/Phenolic

-

Thickness:

-

9.5mm,12mm ,15mm ,18mm ,21mm or as request

-

Size:

-

1220*2440/1250*2500 or as request

-

Item Application:

-

structural ,Ceiling ,Building ,Construction or others

-

Moisture:

-

8%-14%

-

Certificate:

-

CE,FSC,CARB ,ISO9001

-

Item Feature:

-

Waterproof; Competitive price

Quick Details

-

Warranty:

-

1 Year

-

Project Solution Capability:

-

graphic design, Others

-

Application:

-

Construction ,Roofing ,Building ,Ceiling

-

Formaldehyde Emission Standards:

-

E1

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HAISEN

-

Model Number:

-

1220*2440

-

Product name:

-

CDX Pine Plywood

-

Core:

-

Poplar,Pine ,Hardwood, Combi,Eucalyptus

-

Face/back:

-

Pine VNEEER

-

Glue:

-

E0/E1/E2/MR/WBP/Phenolic

-

Thickness:

-

9.5mm,12mm ,15mm ,18mm ,21mm or as request

-

Size:

-

1220*2440/1250*2500 or as request

-

Item Application:

-

structural ,Ceiling ,Building ,Construction or others

-

Moisture:

-

8%-14%

-

Certificate:

-

CE,FSC,CARB ,ISO9001

-

Item Feature:

-

Waterproof; Competitive price

Products Description

|

product name

|

CDX Pine Plywood

|

|

core

|

Poplar, Hardwood, Combi, Birch, Eucalyptus, as your request

|

|

grade

|

BD/CD CC/CC,CC/DD,DD/EE

|

|

glue

|

Phenolic WBP

|

|

size

|

1220*2440mm/1200*2400 or customized

|

|

thickness

|

2-25mm

|

|

country of origin

|

China

|

|

|

Shandong

|

|

usage

|

Indoors, good enough for furniture or construction, packaging or industry

|

|

Minimum order

|

1*20 GP

|

CDX plywood has one side veneer grade “C” and one side veneer grade “D”. ,So we called CDX plywood,It is used primarily by contractors to build exterior walls and roofs.

CDX plywood is manufactured similarly to other types of plywood. Opposing layers of wood veneers are laid at right angles and glued together with resinous glue.

To ensure a sturdy surface and a balanced sheet, an odd number of layers are laid. The odd number of veneer layers allows for an even number of glue layers. This prevents plywood from warping, as it stops the glue from weighing one side.

To make CDX plywood, the veneers are rotary cut from a log. This means that sections of logs are placed in a large lathe to create a continuous spiral cut. The long sheet of veneer is then cut before being glued together.

While this process doesn’t produce attractive grain patterns, it’s a cheap construction method. This is partially why CDX plywood is cheaper than other types of plywood.

To ensure a sturdy surface and a balanced sheet, an odd number of layers are laid. The odd number of veneer layers allows for an even number of glue layers. This prevents plywood from warping, as it stops the glue from weighing one side.

To make CDX plywood, the veneers are rotary cut from a log. This means that sections of logs are placed in a large lathe to create a continuous spiral cut. The long sheet of veneer is then cut before being glued together.

While this process doesn’t produce attractive grain patterns, it’s a cheap construction method. This is partially why CDX plywood is cheaper than other types of plywood.

Details Images

product application

Products packaging(pallet)

Exhibition

Hot Searches