- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

accordance with local voltage

-

Dimension(L*W*H):

-

According to different models

-

Weight:

-

2000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

High quality factory flotation cell for lab flotation machinery supply

-

Machine type:

-

Metal ore flotation beneficiation equipment

-

Processed materials:

-

Separating stones, ores and minerals

-

Spare parts supply:

-

Paid

-

Operation training:

-

provision of service

-

Installation and adjustment:

-

Provide

-

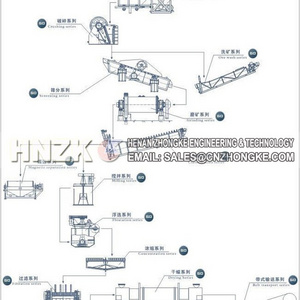

Flowchart:

-

Provide

-

Price:

-

Negotiable and reasonable

Quick Details

-

Production Capacity:

-

0.5-4m/min

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZONEDING

-

Voltage:

-

accordance with local voltage

-

Dimension(L*W*H):

-

According to different models

-

Weight:

-

2000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

High quality factory flotation cell for lab flotation machinery supply

-

Machine type:

-

Metal ore flotation beneficiation equipment

-

Processed materials:

-

Separating stones, ores and minerals

-

Spare parts supply:

-

Paid

-

Operation training:

-

provision of service

-

Installation and adjustment:

-

Provide

-

Flowchart:

-

Provide

-

Price:

-

Negotiable and reasonable

Widely Used Mine Gold Copper Ore Flotation Machine/Beneficiation flotation tank equipment from henan zhongding

Main Features of Flotation machine :

1. Large inhaling capacity and low energy consumption;

2. Complete flotation circuit with inhaling air and pulp, no auxiliaries are needed;

3. Process is easy to be changed;

4. Reasonable circulation of pulp decreases coarse sand sedimentation;

5. Automatic controlling device makes adjustment more convenient. The impeller is rotated by V-belt of motor and produces centrifugal effect with negative pressure. Enough air is inhaled into mixed pulp, and pulp mixes with drug at the same time. Mineral sticks on bubble completely and floats on the surface of pulp to form mineralized bubble. Useful bubble is scraped out by adjusting flashboard height and controlling liquid surfac.

Working Princle: The impeller is rotated by V-belt of motor and produces negative pressure by centrifugal function. Enough air is sucked to mix slurry, and slurry mixes drug at the same time. Mineral sticks on bubble completely and floats on the surface of slurry to form mineralized bubble. Useful bubble is scraped out by adjusting flashboard height and controlling liquid surface.

| Model | SF0.37 | SF0.7 | SF1.2 | SF2.8 | SF4 | SF8 | |

|---|---|---|---|---|---|---|---|

| Volume (m3) | 0.37 | 0.7 | 1.2 | 2.8 | 4 | 8 | |

| Impeller Diameter (mm) | 300 | 350 | 450 | 550 | 650 | 760 | |

| Capacity (m3/min) | 0.2-0.4 | 0.3-0.9 | 0.6-1.2 | 1.5-3.5 | 0.5-4 | 4-8 | |

| Impeller speed (r/min) | 352 | 400 | 312 | 268 | 238 | 191 | |

| Impeller motor | Model | Y90L-4 | Y100L2-4 | Y132M2-6 | Y160L-6 | Y180L-6 | Y250M-8 |

| Power (KW) | 1.5 | 3 | 5.5 | 11 | 15 | 30 | |

| Scraper motor | Model | Y801-4 | Y90S-4 | Y90S-4 | Y100L-6 | Y100L-6 | Y100L-6 |

| Power (KW) | 0.55 | 1.1 | 1.1 | 1.5 | 1.5 | 1.5 |

we can provide avaliable successful cases for your reference.