- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

50 years

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ERA

-

Model Number:

-

AUS011

-

Keyword:

-

Faucet Socket

-

Size:

-

15x1/2''-100x4''

-

Modle:

-

AUS011

-

Color:

-

White

-

Ball Material:

-

PVC

-

Certificate:

-

Kitemark

-

Origin:

-

ZheJiang

-

Type:

-

pvc pipe fitting

-

Brand:

-

ERA

-

Standard:

-

AS/NZS1477

Quick Details

-

Technics:

-

inject

-

Shape:

-

Equal

-

Head Code:

-

round

-

Warranty:

-

50 years

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ERA

-

Model Number:

-

AUS011

-

Keyword:

-

Faucet Socket

-

Size:

-

15x1/2''-100x4''

-

Modle:

-

AUS011

-

Color:

-

White

-

Ball Material:

-

PVC

-

Certificate:

-

Kitemark

-

Origin:

-

ZheJiang

-

Type:

-

pvc pipe fitting

-

Brand:

-

ERA

-

Standard:

-

AS/NZS1477

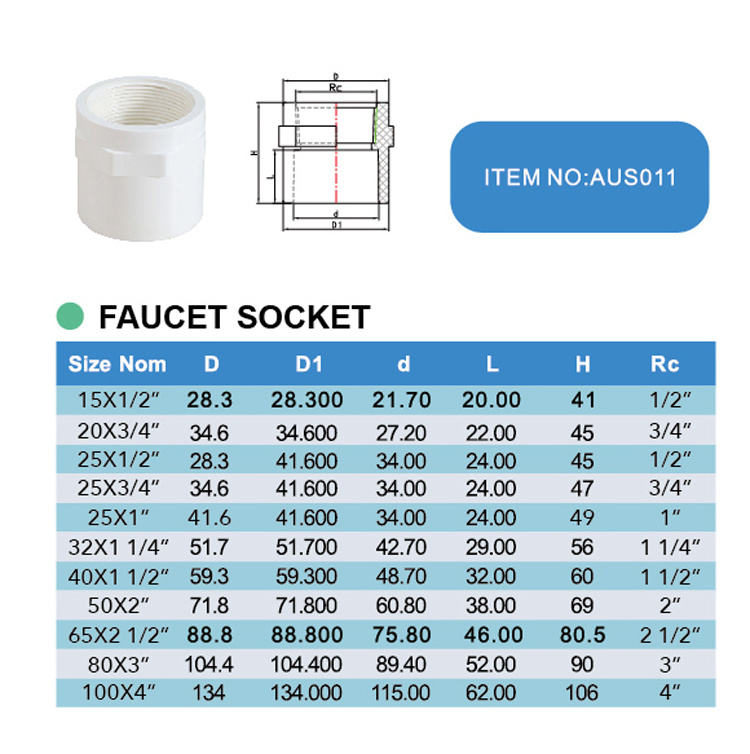

Products Description

|

Model Number

|

AUS011

|

Material

|

PVC

|

|

Description

|

Faucet Socket

|

Standard

|

AS/NZS 1477

|

|

Temperature

|

Max 60℃ / 140°F

|

Working Pressure

|

PN10 10Bar 1.0Mpa

|

|

Connection

|

Thread & Socket

|

Color

|

White

|

Application and Advantages

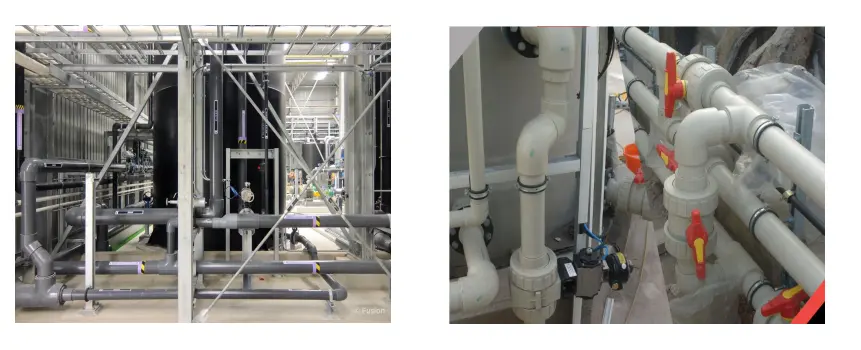

Product Applications

1. Major potable water supply trunk and reticulation mains.

2. Irrigation and turf watering systems.

3. Industrial process pipelines.

4. Effluent pipelines for pumped sewage, industrial and rural wastes.

2. Irrigation and turf watering systems.

3. Industrial process pipelines.

4. Effluent pipelines for pumped sewage, industrial and rural wastes.

5. Slurry pipelines carrying abrasive and corrosive mine or quarry materials.

Product Advantages

|

Adavantages

|

Benefits

|

|

Watermark certified by Sai Global

|

Authoritative quality assurance

|

|

Excellent corrosion resistance

|

Long service life

|

|

Insulation resistance

|

Do not suffer from electrolytic corrosion

|

|

Light weight

|

Ease of handling and lower installation costs

|

Installation Manual

1.

Pipe cutting:

After taking the appropriate length, use a file to remove burrs and sharp edges.

2. Bonding of pipes and fittings:

Before bonding, a trial installation must be carried out to determine and mark the installation position. After cleaning, the adhesive should be evenly applied to the outside of the pipe end and the inside of the socket. After coating, insert and stick. and keep the pipes clean.

3.

Ensure there is no leakage during use:

Pipes must be installed with reliable seals.

4. Prevent deformation of plastic pipes:

Since plastic pipes have certain plasticity, brackets or elevators should be installed every 0.6M when installing horizontal pipes.

5. The water supply pipeline should be kept away from the heat source:

The clear distance between the standpipe and the furnace edge should not be less than 400MM, and the clear distance between the standpipe and the heating pipe should not be less than 200MM.

6. Used for covering soil and sealing pipes:

After construction is completed, the pressure test must be qualified.

Hot Searches