- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Yinhao

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

according to customer needs

-

Motor Power (Kw):

-

45

-

Power (kW):

-

2.2

-

Weight (KG):

-

100 KG

-

Marketing Type:

-

New Product 2024

-

Keywords:

-

roller shell

-

Pellet size:

-

3-5 mm

-

Mould Material:

-

Stainless Steel or customized

-

Application:

-

Make Biomass Pellets

-

Pellet diameter:

-

2-6mm

-

Product:

-

Vehicle Mould

-

Weight:

-

100kg

-

Certification:

-

CE ISO

-

Power:

-

45-132kw

Quick Details

-

Pellet Diameter (mm):

-

6 - 12

-

Output (kg/h):

-

800 - 1200 kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yinhao

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

according to customer needs

-

Motor Power (Kw):

-

45

-

Power (kW):

-

2.2

-

Weight (KG):

-

100 KG

-

Marketing Type:

-

New Product 2024

-

Keywords:

-

roller shell

-

Pellet size:

-

3-5 mm

-

Mould Material:

-

Stainless Steel or customized

-

Application:

-

Make Biomass Pellets

-

Pellet diameter:

-

2-6mm

-

Product:

-

Vehicle Mould

-

Weight:

-

100kg

-

Certification:

-

CE ISO

-

Power:

-

45-132kw

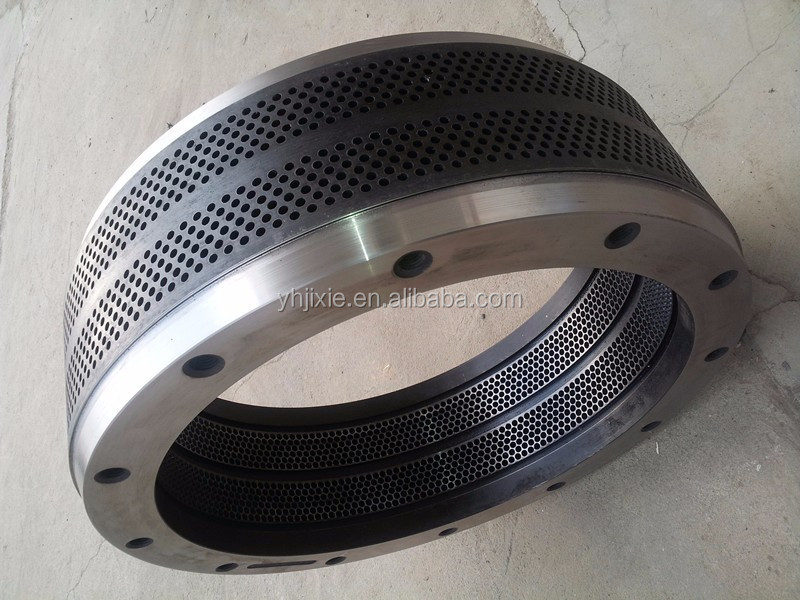

Ring die spare parts/pellet mill parts/matrix/roller sell

Ring Die for Pellet Mill/ring die rollers

1.Used in various pellet mills made in China and overseas

2.Customized specifications are accepted

3.Sort of roller: corrugation roller, dimpling roller

4.Materials: alloy steel, stainless steel

5.Technical parameters: open end, closed end, HCE, HOE, HTP, straight dimple, opening of dimple

Roller shell feed machine spare part high grade chicken pellet machinery with

Product details

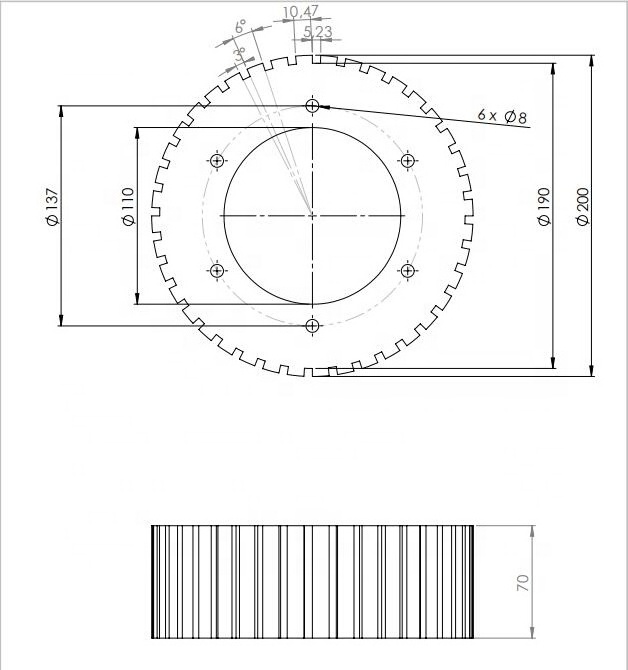

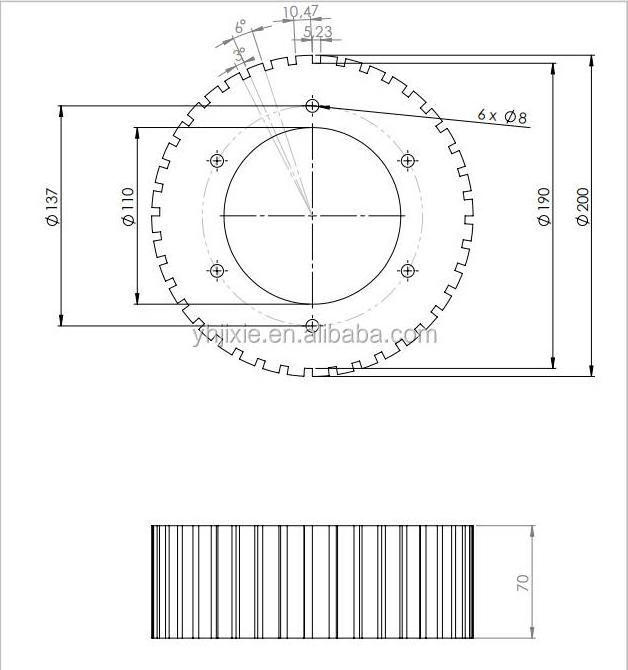

| Name | roller shell |

| Application | Make Animal Feed |

| Raw material | stainless steel/ 100Cr6/20MnCr5/40Cr. |

| Brade | OEM, Custom-made |

| Hardless | HRC56-62 |

| Quality | Top Level |

| Package | Wooden Box Package |

| Product Keywords | roller shell feed machine spare part,high grade chicken feed pellet machinery with roller shell |

1. Material: 20CrMnTi

2. Hardness: HRC52-54

We are specialized in the production of feed pellet mill and biomass pellet mill roller shells,yeaely capacity is 200,000

pcs, we exported our roller shells to all around the world.

Automatic NC Saw applicable to mass production and continuous cutting, Accurate loading weight for raw material.

Own forging to ensure quality of material.

lathe processing, more accurate dimension.

Fully automatic corrugated/dimple drilling machine; Reasonable tooth/hole arrangement, enhance the wear resistance of roller.

Heating treatment with seals the box multi-purpose stove to make sure HRC56-62 of hardness.

grinder processing, product size more accurate, more concentricity.

Testing equipment to ensure product quality

Pellet dies must resist abrasion, corrosion from chemical exposure and breakage caused by the physical stresses of pellet formation. The optimum die combines high resistance to abrasion, breakage and corrosion with maximum productivity. Our expertise enables us to precisely match the die specification to your required formulation, even if it means customizing a die pattern to meet your exact needs. The wide range of used dies with hole diameters from 2 mm to 12 mm guarantees the production of pellets with a required size.

Die Materials

1. Alloy dies are the choice for many feed processors because of their good abrasion and breakage resistance

2. Chrome dies have superior corrosion resistance, making them the choice for processing operations involving corrosive chemicals

3. stainless steel dies have the best abrasion and breakage resistance as well as good corrosion resistance