- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Sino-Tech

-

Weight:

-

350 KG

-

Dimension(L*W*H):

-

2*0.8*1.6m

-

Usage:

-

Foil washer liner inserting machine

-

Automatic grade:

-

Automatic

-

material:

-

stainless steel

-

Packaging type:

-

Case

-

Function:

-

Inserting pre-cut foil washer into caps

-

Keyword:

-

Cap lining machine

-

Belong:

-

Other Packaging Machines

-

Drive:

-

Automatic

-

Capacity:

-

250 pcs/min

Quick Details

-

Voltage:

-

220/380V

-

Power:

-

1.5KW

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sino-Tech

-

Weight:

-

350 KG

-

Dimension(L*W*H):

-

2*0.8*1.6m

-

Usage:

-

Foil washer liner inserting machine

-

Automatic grade:

-

Automatic

-

material:

-

stainless steel

-

Packaging type:

-

Case

-

Function:

-

Inserting pre-cut foil washer into caps

-

Keyword:

-

Cap lining machine

-

Belong:

-

Other Packaging Machines

-

Drive:

-

Automatic

-

Capacity:

-

250 pcs/min

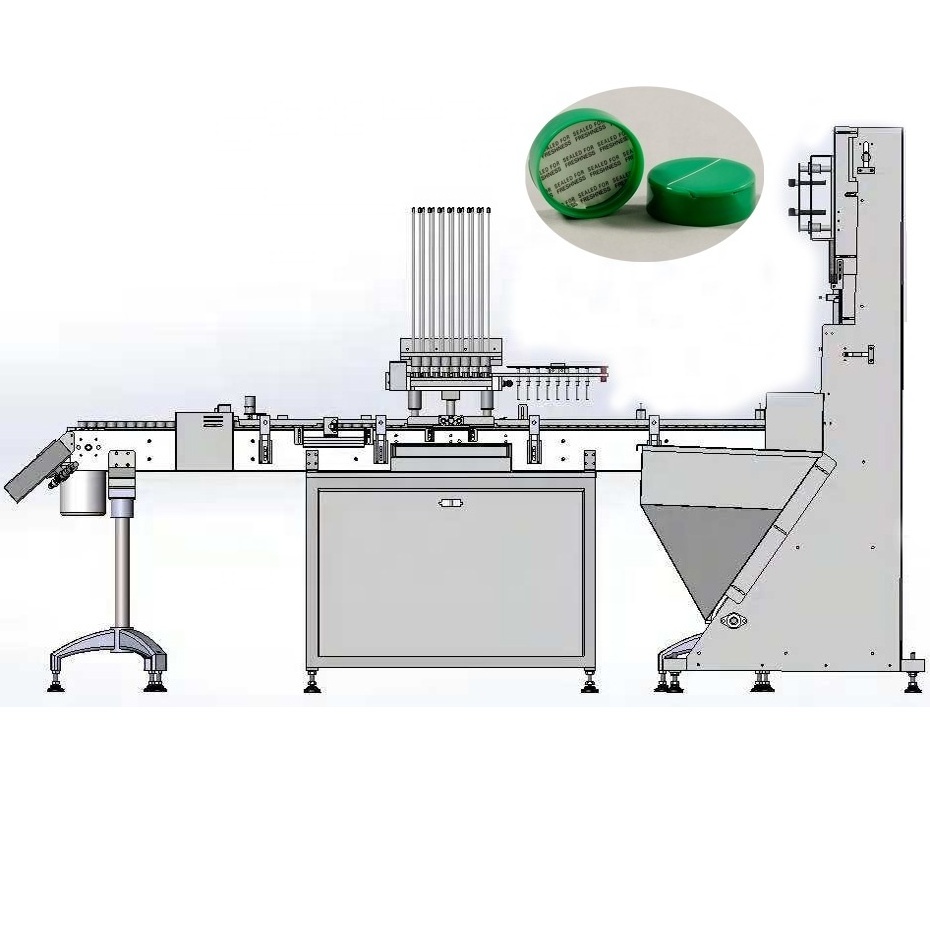

High speed cap lining machine foil washer liner inserting machine factory

Application:

Cap liner die cutting and inserting wadding lining machine is an ideal liner inserting machine which is widely applied in cap factories, liner factories, food products factories, daily chemical factories, packing factories, etc..

Machine Features:

1.Automatic cap liner inserting has replaced manual work, which substantially raises the work efficiency.

2. Liner inserting features good accuracy, high speed and high efficiency; products are safe and healthy.

3. The machine adopts a conveyer belt to convey caps; the positions of caps will be fixed when the caps reach the liner inserting positions. The vacuum liner taking device will take out the liners for inserting. When caps are of different sizes, the replacement of mould, liner cylinder and sucking disc is simple and convenient.

4. A conveying locating unit with mechanical transmission is adopted, which contributes to stable and reliable operation of the machine. It is applicable for caps and liner of various specifications..

5. The machine has the function of automatic detection of finished products. If the liner is not inserted to the cap or the reverse side of the liner is inserted to the cap, the detection device will automatically sift these nonconforming caps and transmit them to the defective product area, which guarantees the conformance rate of caps.

6. This machine is equipped with safety protection devices for stop of the machine when there is no cap or liner, thus realizing human-based operation. (Optional)

7.set number of caps, which also greatly improves the efficiency of subsequent work.