- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

2500 KG

-

Dimension(L*W*H):

-

1600*850*1300

-

Name:

-

Biomass Sawdust Burner Machine

-

fuel::

-

biomass energy for fuel

-

fuel consumption:

-

70-4500(kg/h)

-

Core Components::

-

wood pellet burner

-

raw materail:

-

Sawdust, leaves, rice Husk, wood

-

used for:

-

oil/gas/coal fired boiler

-

efficient:

-

more than 90% of burning rate

-

Raw material:

-

wood pellets

-

application:

-

incinerator,fuel oil boiler,drying equipment,greenhouse

-

calorific value::

-

3000-180000Kcal/h

Quick Details

-

Warranty:

-

2 years

-

Place of Origin:

-

Henan, China

-

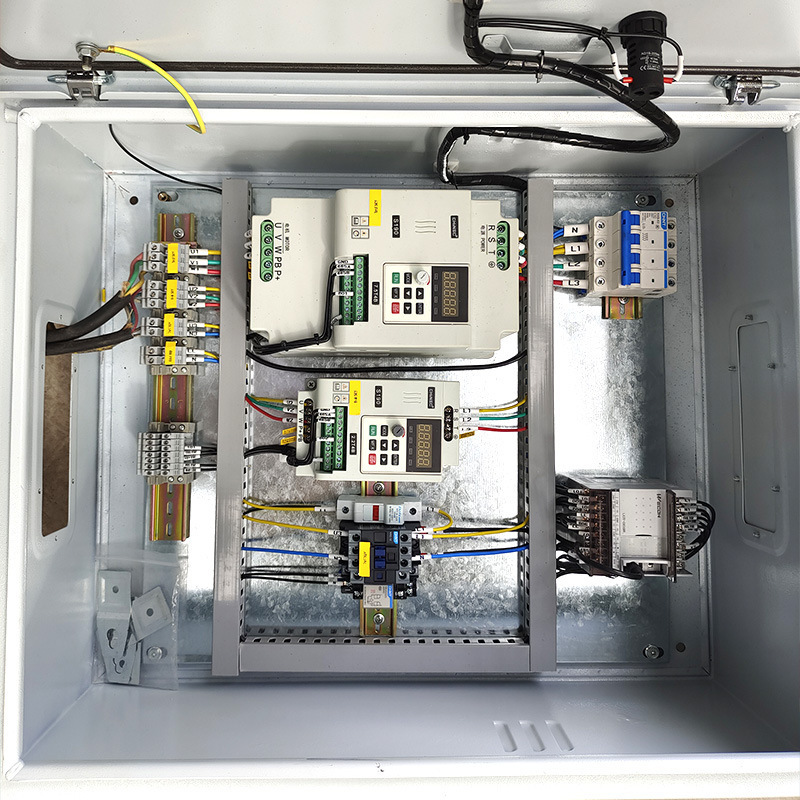

Voltage:

-

220V/380V

-

Weight:

-

2500 KG

-

Dimension(L*W*H):

-

1600*850*1300

-

Name:

-

Biomass Sawdust Burner Machine

-

fuel::

-

biomass energy for fuel

-

fuel consumption:

-

70-4500(kg/h)

-

Core Components::

-

wood pellet burner

-

raw materail:

-

Sawdust, leaves, rice Husk, wood

-

used for:

-

oil/gas/coal fired boiler

-

efficient:

-

more than 90% of burning rate

-

Raw material:

-

wood pellets

-

application:

-

incinerator,fuel oil boiler,drying equipment,greenhouse

-

calorific value::

-

3000-180000Kcal/h

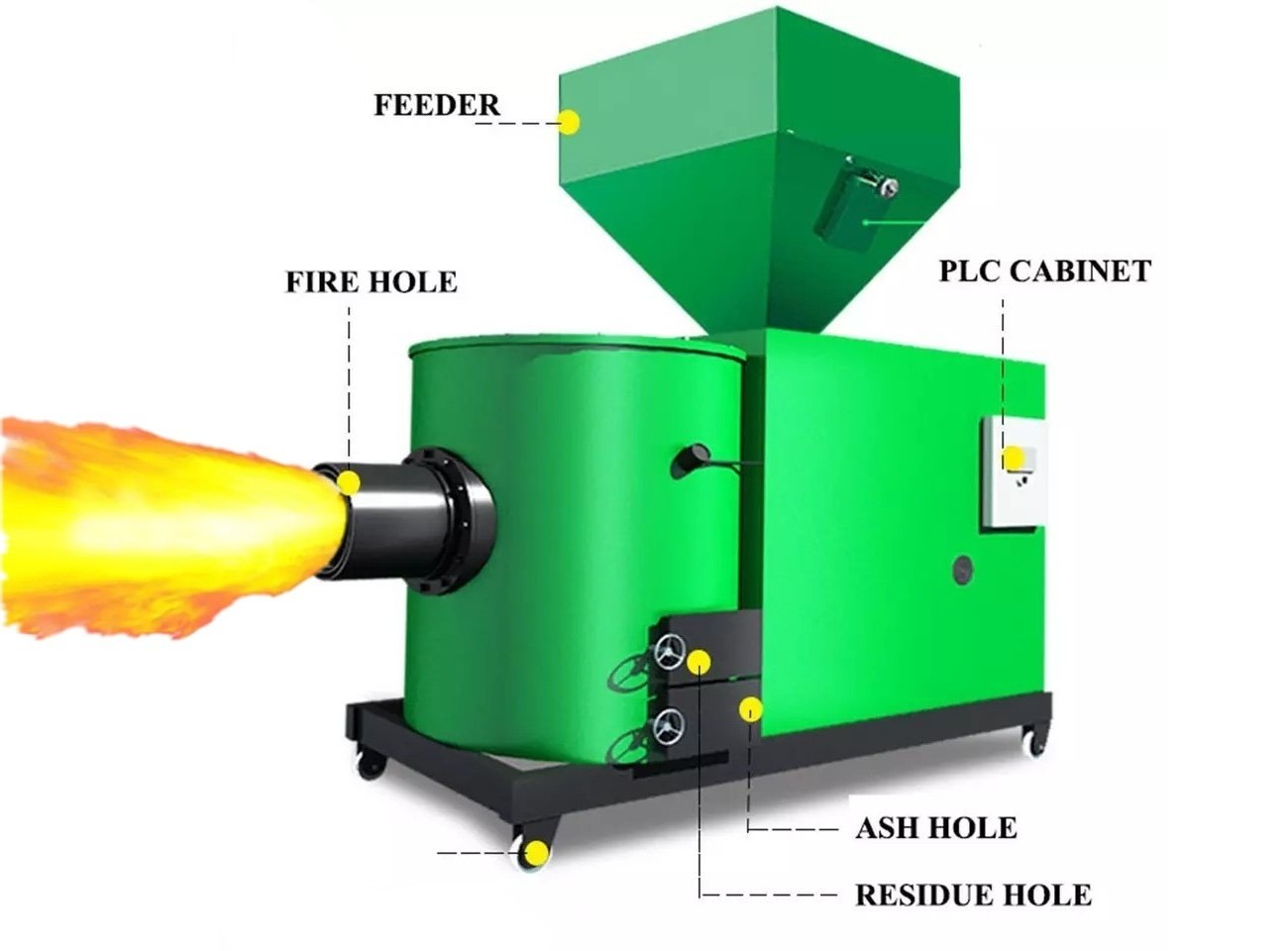

6000000 Kcal Rice Husk Wood Dust Sawdust Straw Biomass Pellet Wood Chip Burner

biomass particle burner wood pellet making machine biomass burner wood chips sawdust biomass burner for dryer and boiler is a biomass semi-gasification automatic control burner.

biomass pyrolysis burner using biomass particles, wood chips, wood powder, sawdust and other organic biomass as fuel, generally divided into air-cooled Two models of burner and water-cooled burner.

Introduction of China Biomass wood pellet burner

1) Each pellet Burner for boiler and dryer controlled with automatic igniter.

2) Low pressure stater means biomass pellet burner for boiler will be started automatically in low pressure.

3) Separate out dregs automatically.

4) The biomass burner would stop the leak forever, lifetime warranty.

5) Fuel save 60% than Electric save 75% than natural gas save 50%-70% than liquefied gas save 45%.

6) Large biomass granule can be burned and burning cost is cheaper.

|

Model |

Rated calorific value(10000Kcal) |

Rated Voltage(V) |

input power(KW) |

full load consumption(kg/H) |

Weight (T) |

|

CS-20-1(L/R) |

15-25 |

220 |

0.75 |

50 |

0.6 |

|

CS-30-1(L/R) |

25-35 |

220 |

0.75 |

75 |

0.7 |

|

CS-45-1(L/R) |

35-55 |

220 |

1.12 |

115 |

1 |

|

CS-60-1(L/R) |

50-80 |

220 |

1.9 |

150 |

1.6 |

|

CS-90-1(L/R) |

80-100 |

380 |

3.1 |

225 |

2.2 |

|

CS-120-1(L/R) |

90-120 |

380 |

3.7 |

300 |

3 |

|

CS-180-1(L/R) |

120-180 |

380 |

5.25 |

450 |

3.8 |

|

CS-240-1(L/R) |

180-240 |

380 |

8.45 |

600 |

4.8 |

|

CS-300-1(L/R) |

240-300 |

380 |

10.45 |

750 |

8 |

|

CS-360-1(L/R) |

300-360 |

380 |

10.45 |

900 |

9 |

|

CS-420-1(L/R) |

360-420 |

380 |

10.8 |

1050 |

10 |

|

CS-480-1(L/R) |

420-480 |

380 |

10.8 |

1200 |

11 |

- Biomass pellet burner is wildly used in various industries such as boiler, casting machine,industrial stove,smelting furnace,kitchen equipment,drying equipiment ,food drying equipment,ironing equipment , lacquer equipment,Road building machinery equipment,Industrial annealing furnace,asphalt heating equipment .

- Biomass pellet burner adopts biomass pellet as fuel, burner is more wildly used and has lower requirement for fuel quality. Working Performance use biomass pellet as fuel burning efficiency is larger than 95%,Boiling type half gasification combustion and tangent of swirling air distribution design, makes fuel fully burned .

-

Fully burned and burning stable. In micropressure situation not happen tempering and flamelifting phenomenon heating load can be

wildly adjusted, can quickly adjust between 30%-130% of rated load,Initiate Block reaction is sensitive no pollution and high efficient environmental protection, burn reproducible biomass fuel,Realize the sustainable use of energy. It adopts low temperature section burning technolgoy, the nitrogen oxides, sulfur dioxide ,dust etc in smoke are low, which is the best substitute for coal stove etc -

Easy operating,convenient Maintenance, automatical feeding, automatical discharging,automatical igniting, automatical control temperature ,automatical 24 working hours without unattended substation.

low invest, low working cost ,wide belt burning with frequency conversion, more fit for user requirement and can change burning type ,controling as per their requirement.

Application:

biomass wood pellet burner is widely used in boiler soil gas boiler fixed grate fired boilers, coal boiler pulverized coal,industrial kilns, furnaces, dryer machine, spraying production line and other supporting energy saving.

high efficiency wood pellet granules making machine sawdust pellet maker machine for farming

This series Biomass flat die pellet machine is a new type of pellet machine, specifically aimed at biomass materials. It is widely used for pelleting various biomass materials. Transmission gears adopt high quality alloy steel, surface treatment of cemented quenching, after elaborate processing, smooth transmission, low noise, large load capacity, low temperature rise, long working life. Adding strong gluten in the bottom, high anti-pressure ability. It is suitable for home using or small enterprises producing biomass pellet fuel or feed. It can be configured to diesel or electric motor, it is mobile flexible and simple to operate.

The Development Prospect Of The Wood Pellets Production

How to make your own pellet with our feed granulator? The complete feed pellet production line is composed the following steps.

Step1: Crushing Process

Crusher is used to crush the raw materials to suitable size before pelletizing.

Step2: Mixing Process

Mixer is used to mix different raw materials. Our mixer is specially designed for discharge mechanism and large open Angle, so it has the advantage of discharge rapidly, less residue, good sealing and high mixing speed.

Step3: Pelletizing Process

Feed pellet machine is the most important part of the whole feed pellet production process. Our feed pellet machine got high feedback from customers for advanced product design, reasonable structure and excellent production.

Step4: Cooling Process

After pelletizing, the temperature of pellet is usually between 60-80 degrees and the moisture content is close to 15%. For storage purposes, a cooler must be used to reduce their surface temperature and prolong the storage time.

Step5: Packing Process

The feed pellet is easy to be destroy in damp conditions. In order to facilitate transport and maintain feed pellets hardness, timely packaging is necessary.

Package

1.Machines will be packed in standard and quantities boxes ,the production will have a safe and complete journey from our factory to your place.

2.Packaging details standard export wooden case or in container.

Shipping

1,We will serve your shipping method about ocean transport ,air lift ,freights and so on.

2,The delivery time is usually 7-15 working days upon receipt of your payment.