- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

DS001TS

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Tunsing

-

Model Number:

-

DS001TS

-

Type:

-

pes hot melt adhesive film

-

Release Liner:

-

Glassine release paper

-

Colour:

-

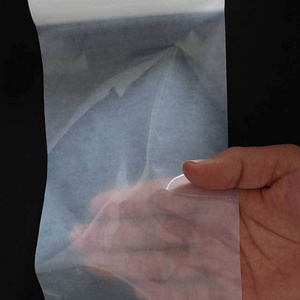

Milky white translucent

-

Thickness:

-

0.025mm-0.3mm

-

Width:

-

5mm-1580mm

-

Conventional Width:

-

50cm 100cm

-

Conventional thickness:

-

0.05mm,0.10mm, 0.15mm

-

Activation Temperature:

-

116-150℃(Tunsing)

-

Melt Flow Index:

-

32±15g/10min; Condition:ASTMD1238-04

-

MeltingRange:

-

80-105℃(TunsingDSC214

-

Finished Products specification:

-

50mm*100yards/roll

Quick Details

-

CAS No.:

-

32472-85-8

-

Other Names:

-

pes hot melt adhesive film

-

MF:

-

DS001TS

-

EINECS No.:

-

DS001TS

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Tunsing

-

Model Number:

-

DS001TS

-

Type:

-

pes hot melt adhesive film

-

Release Liner:

-

Glassine release paper

-

Colour:

-

Milky white translucent

-

Thickness:

-

0.025mm-0.3mm

-

Width:

-

5mm-1580mm

-

Conventional Width:

-

50cm 100cm

-

Conventional thickness:

-

0.05mm,0.10mm, 0.15mm

-

Activation Temperature:

-

116-150℃(Tunsing)

-

Melt Flow Index:

-

32±15g/10min; Condition:ASTMD1238-04

-

MeltingRange:

-

80-105℃(TunsingDSC214

-

Finished Products specification:

-

50mm*100yards/roll

Pes Polyester Roll Hot Melt Glue Adhesive Film Embroidered Badge

Product Description

Product: DS001TS

Description

:

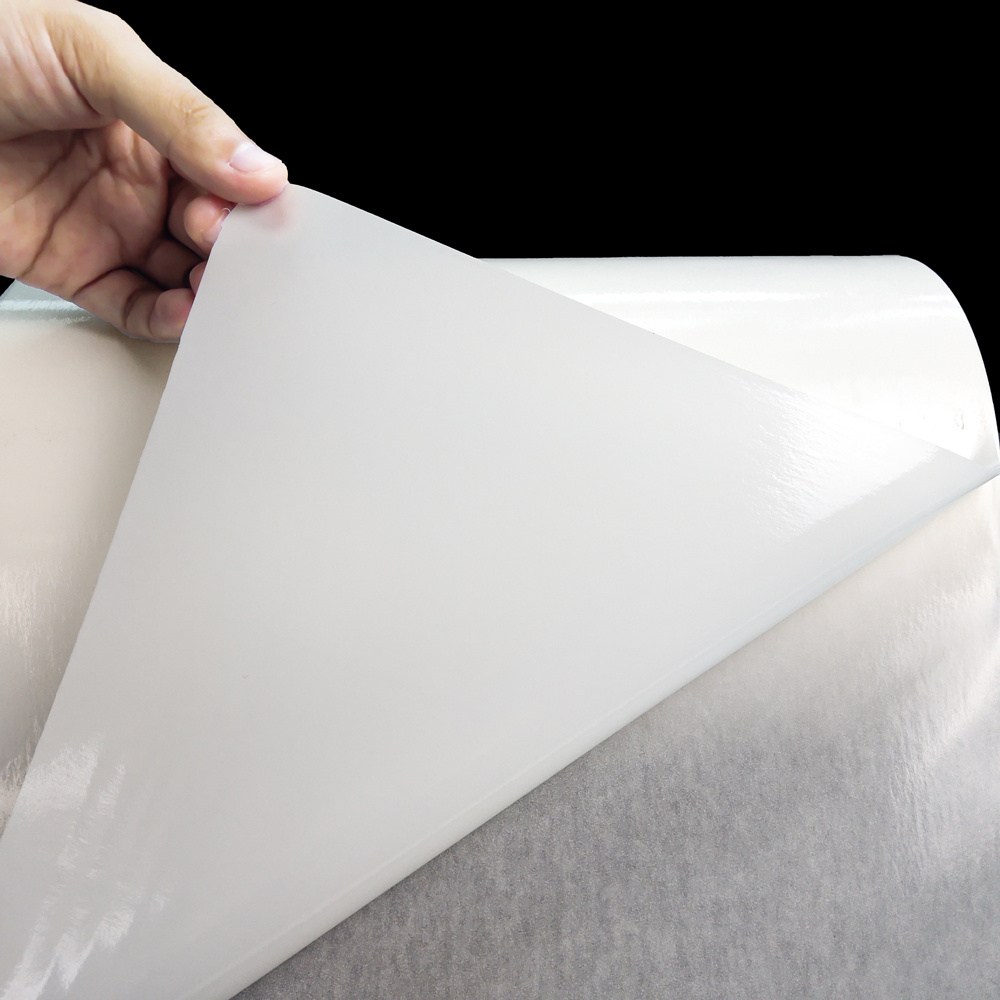

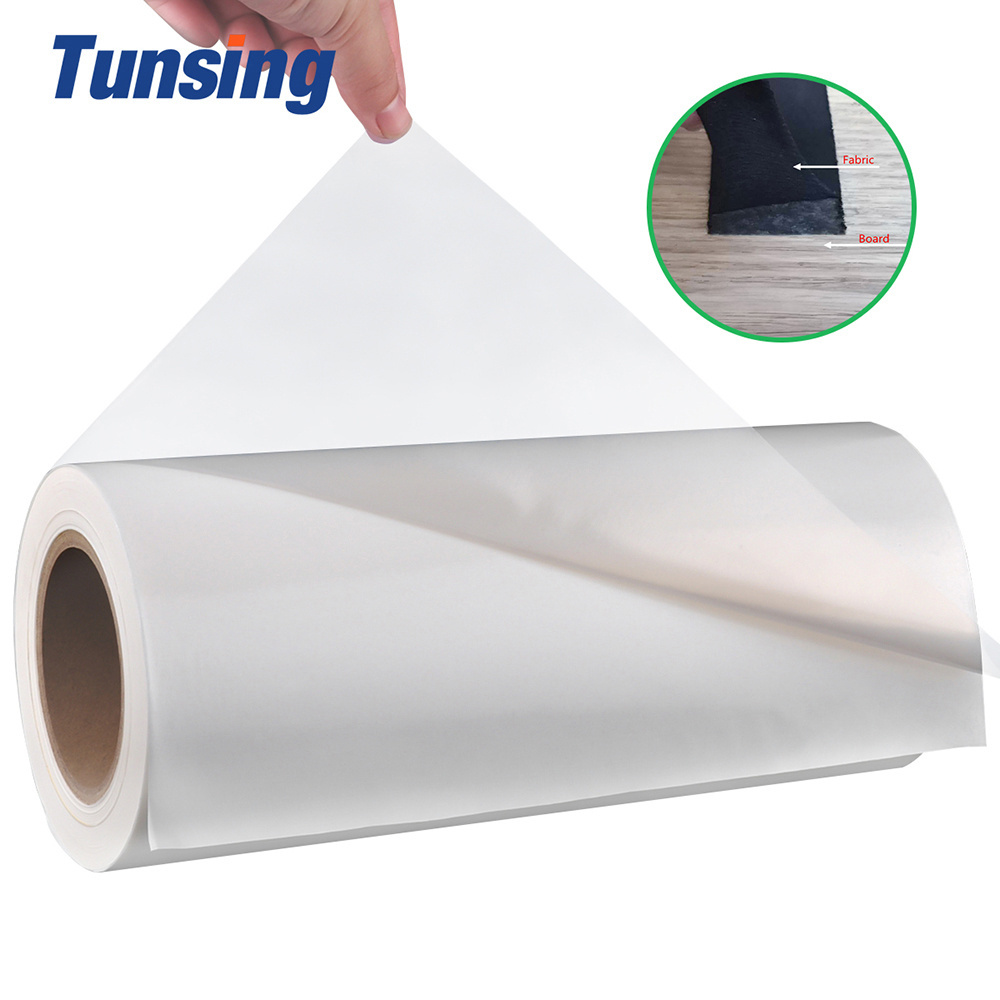

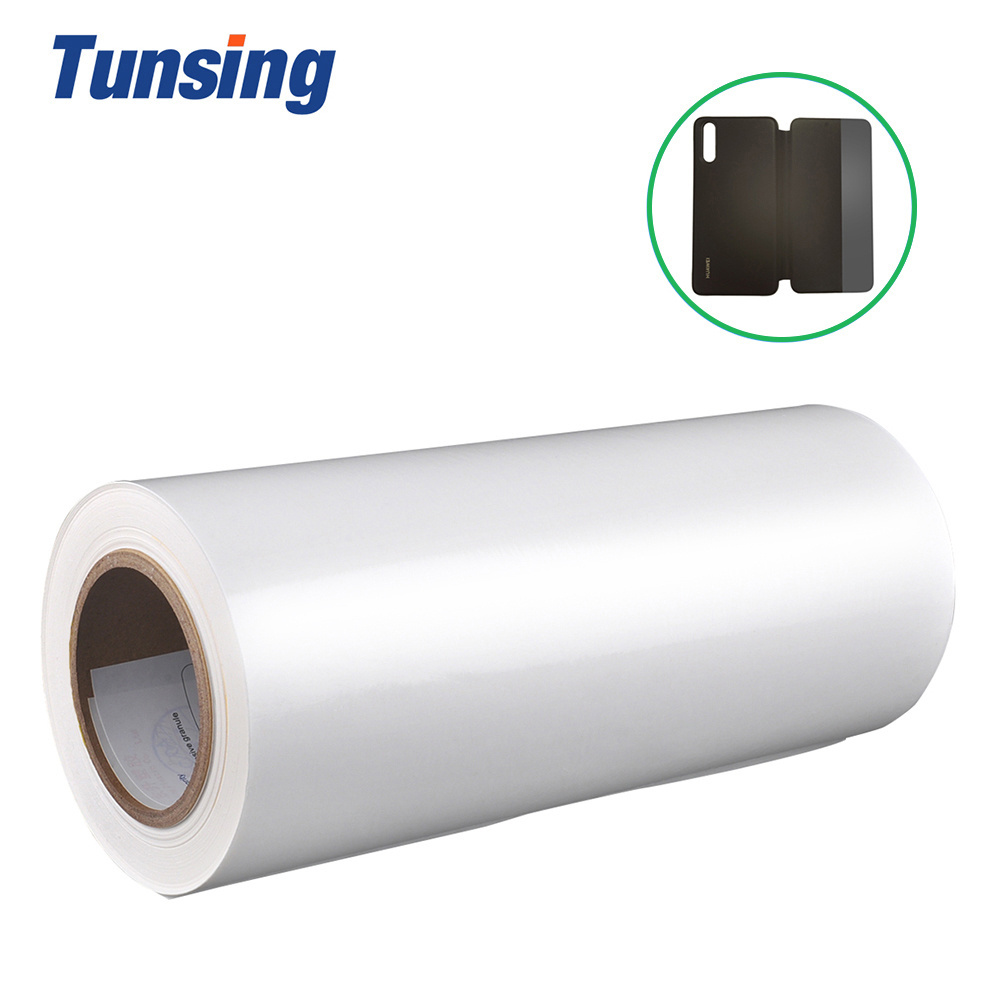

This product is a thermoplastic film hot melt adhesive, entrusted to the release of paper, can be repeatedly heated plasticized bonding.This kind of hot melt adhesive has excellent adhesion to textile products, PVC, PC.This product is resistant to dry cleaning and 40℃ washing.

Applications:

DS001TS is applied in clothing, footwear, accessories, reflective materials, handbags, bags, embroidery, crafts bonding.

Composition:

Copolyester

Physical Characteristics:

|

Colour

|

Milky white translucent

|

Release Protection

|

Glassine Release Paper

|

|

Proportion

|

1.15±0.02g/cm³

|

Conventional Thickness

|

0.05mm,0.08mm,

0.10mm,0.12mm,

0.15mm,0.18mm

|

|

Melting Range

|

90-120℃

(Tunsing DSC 214) |

Width

|

10mm-1480mm

|

|

Liquidity Index

|

32±15g/10min

(ASTM D1238-04)

|

Conventional Width

|

500mm,1000mm,

1280mm,1480mm

|

|

Activation Temperature

|

116-150℃(Tunsing)

|

Conventional Length

|

100 yards

|

|

Washing Resistant

|

40℃

|

Finished Product

|

500mm*100yards/roll

|

Recommended Bonding Conditions:

|

First Lamination

|

|

Second Implanting

|

|

||

|

Mechanical Mold Temperature

|

130℃-160℃

|

Mechanical Mold Temperature

|

130℃-170℃

|

||

|

Hot Pressing Time

|

5-15 seconds

|

Hot Pressing Time

|

8-25 seconds

|

||

|

Pressure

|

0.3-0.6mpa

|

Pressure

|

0.3-0.6mpa

|

||

1.Bonding temperature and pressure and time relate to the bonding strength of the film to the material. The bonding temperature must be close to the temperature set by the machine, the pressure must be uniform, and the mold and press rolls must be flat.2. The bonding conditions used will vary between machines and materials. The conditions indicated here are only basic. The most ideal bonding conditions should be established by manufacturing for the specific

application.

Note: The seller hereby declares that Tunsing will refuse to accept the assurance of the components of the manufacturing process.Tunsing firmly believes that the information content is reliable. However, the claims for possible problems will not be guaranteed for the components of a particular process. Before use, the manufacturer must determine the suitability of the product for the items to be used. The user must bear the risks and possible problems in the various manufacturing stages of testing and use. The Seller and the manufacturer shall not be liable for any direct injury, loss, damage or misuse.

Customer Feedback

Related products

Black DTF Powder

DTF PET Printing Film

Hot Melt Adhesive Film

Hot Searches