- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

600 ml

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

GUOZHU

-

Year:

-

2023

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

11145*2100*2200

-

Hollow part volume:

-

600ml

-

Power (kW):

-

92

-

Weight (KG):

-

11000 KG

-

integrated:

-

blowing filling capping

-

Marketing Type:

-

New Product 2021

-

Blow Moulding Type:

-

Stretch Blow Moulding

Quick Details

-

Neck Diameter(mm):

-

38 mm

-

Max.Bottle Diameter(mm):

-

68 mm

-

Max.Bottle Height(mm):

-

240 mm

-

Bottle Volume(ml):

-

600 ml

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

GUOZHU

-

Year:

-

2023

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

11145*2100*2200

-

Hollow part volume:

-

600ml

-

Power (kW):

-

92

-

Weight (KG):

-

11000 KG

-

integrated:

-

blowing filling capping

-

Marketing Type:

-

New Product 2021

-

Blow Moulding Type:

-

Stretch Blow Moulding

Product Paramenters

Guozhu FSSC Certificate

FSSC certificate refers to the certificate of Food Safety System Certification. FSSC 22000 is a global standard for food safety management systems designed to ensure food safety and quality during food production. The certificate is issued by the

international Foundation for Food Safety Certification and is widely recognized and adopted by many organizations and businesses.

FSSC 22000 certification covers all aspects of food safety management, including food safety policy, risk assessment, control measures, monitoring and improvement.

Obtaining an FSSC certificate can help companies improve food safety management, enhance consumer trust in products, and meet the requirements of the international market.

Obtaining an FSSC certificate can help companies improve food safety management, enhance consumer trust in products, and meet the requirements of the international market.

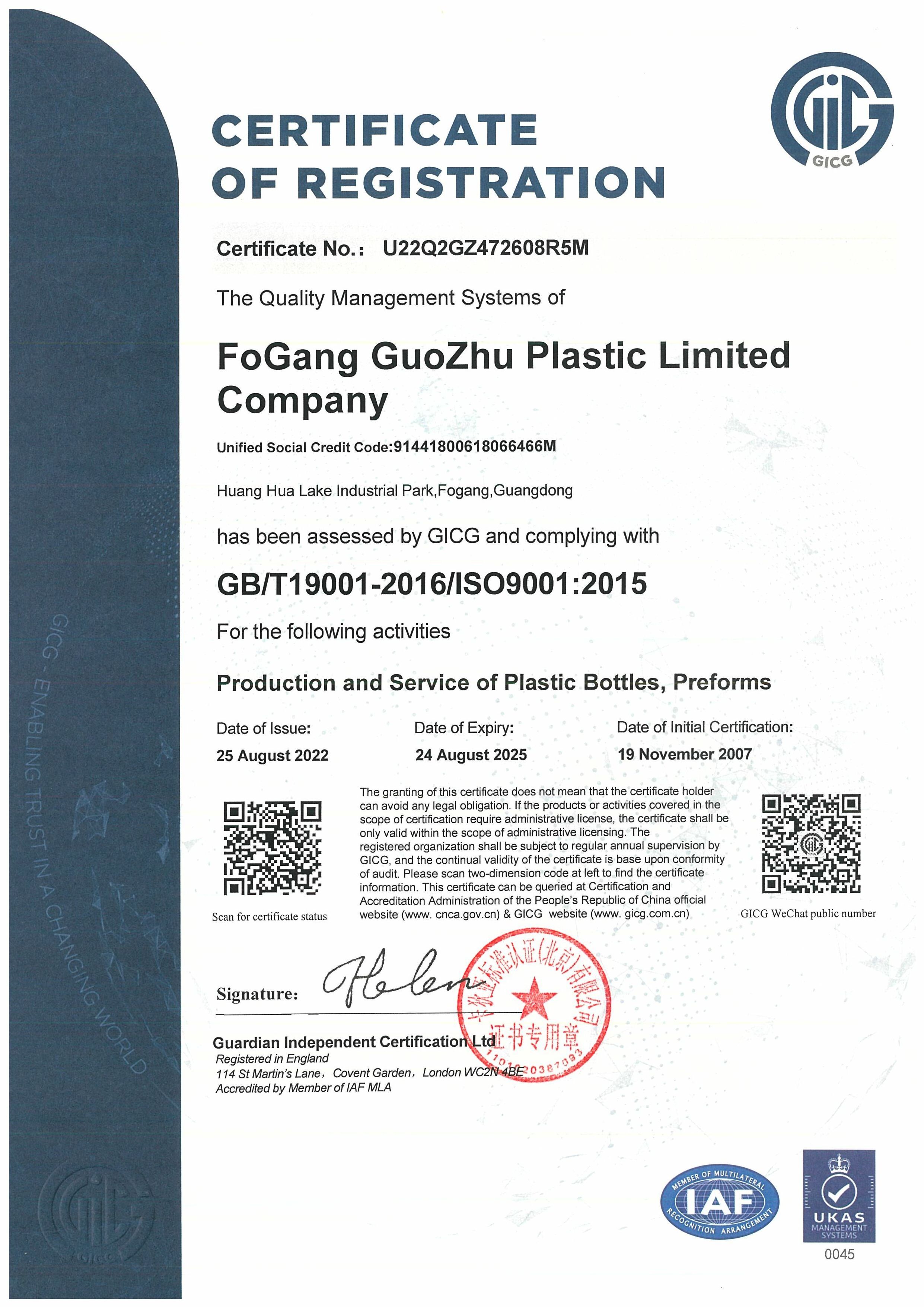

Guozhu ISO Certificate

ISO certificate is the certification of the quality management system, environmental management system, information security management system of an organization, product or service. Obtaining an ISO certificate can demonstrate that the organization, product or service meets the requirements of international standards and has certain quality, environmental or safety management capabilities.

|

No.

|

Automatic Bottle Blowing Machine

|

|

Filling machine

|

|

|||

|

1

|

PMLBGX-3-18-5

|

|

|

|

|||

|

2

|

Mold Cavity

|

3 Cavities

|

Capacity Bottles/Hour

|

2,000~3,000 pcs

|

|||

|

3

|

Max Volume of Bottle

|

6 L

|

Filling Method

|

Quantitative

|

|||

|

4

|

Capacity

|

2,400~2,600 bph

|

Number of Filling Heads

|

18

|

|||

|

5

|

Max Diameter of Bottle

|

170 mm

|

Number of Rotating Heads

|

5

|

|||

|

6

|

Max Bottle Mouth Size

|

55 mm

|

Max Filling Volume

|

6 L

|

|||

|

7

|

Max Height of Bottle

|

350 mm

|

Max Bottle Mouth Size

|

55 mm

|

|||

|

8

|

Max Height of Preform

|

210 mm

|

Bottle Cap Disinfection and Cleaning Time

|

20 s

|

|||

|

9

|

Clamping Stroke

|

190 mm

|

Control Air Pressure

|

0.8 Mpa

|

|||

|

10

|

Bottom Die Stroke

|

Mechanical Synchronization

|

Sterile Air Drying Time

|

2 s

|

|||

|

11

|

Rotor Spacing

|

72 mm

|

Sterile Water Rinse Time

|

4 s

|

|||

|

12

|

Use Power

|

35~50 KW

|

System Driver

|

Servo Sync

|

|||

|

13

|

Low Pressure

|

0.8 Mpa

|

Total Power

|

5.5 KW

|

|||

|

14

|

High Pressure

|

2.6~4.0 Mpa

|

Equipment Floor Area

|

2,900*2,645*2,300mm

|

|||

|

15

|

Equipment Footprint

|

6,055*2,560*3,200 mm

|

Weight

|

4 t

|

|||

|

16

|

Mold Thickness

|

280 mm

|

|

|

|||

|

17

|

Number of Tube Layers

|

12

|

|

|

|||

|

18

|

Number of Heating Rotors

|

108

|

|

|

|||

|

19

|

Installed Power

|

125 KW

|

|

|

|||

|

20

|

Low Pressure Air Consumption

|

High Pressure Gas Recovery

|

|

|

|||

|

21

|

High Pressure Air Consumption

|

10 m

3

/min

|

|

|

|||

|

22

|

Weight

|

7.5 t

|

|

|

|||

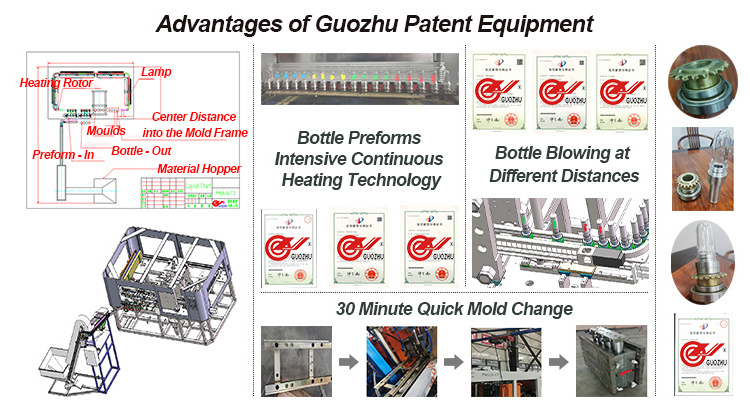

Why Choose Us

The Newest Products

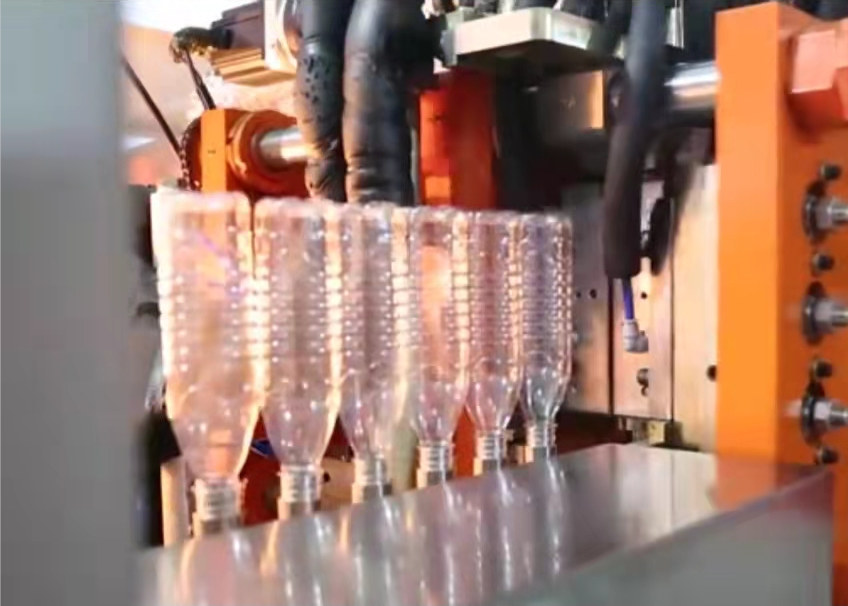

PMLBGX series are the stable two-step blow-fill-cap stretch automatic blowing machine, filling machine and bottle capping machine. It can be used from 3 cavity to 9 cavity with a max speed of 18,000 bottles per hour, are suitable for max volume 6,000 ml plastic bottle with any kind of beverage bottle, sparkling beverage bottle, pure water bottle, mineral water bottle, and high temperature resistance plastic bottles.

Recommend Products

PP High Speed Bottle Blow-Fill-Cap Machine

4/6/8

cavities

5,000 ~ 10,000 bph

5,000 ~ 10,000 bph

For PP Infusion Bottles

4/6/8

cavities

3,200 ~ 7,200

bph

For PP Bottles

3/4/6/8

cavities

3,000 ~ 8,000

bph

PP

High Speed

Bottle Blowing Machine Connected to Injection Molding Machine

4/6/8

cavities

5,000 ~ 10,000 bph

5,000 ~ 10,000 bph

PET Cosmetic Bottle Blowing Machine Connected to Injection Molding Machine

2/4/6

cavities

1,000 ~ 4,200

bph

For PET Jars

(Wild-mouth Bottles )

2/3/4/6

cavities

1,500 ~ 6,000

bph

PET High Speed Bottle Blow-Fill-Cap Machine

3/6/9

cavities

2,400 ~ 18,000

bph

High Speed PET Bottle Blowing Machine Capable of Connecting Different Types of Filling Machines

3/6/9

cavities

2,400 ~ 18,000

bph

For PET Big Bottles

( 10 - 20 L )

2/3/4

cavities

1,500 ~ 3,100

bph

For PET Cold Filling or Hot Filling Bottles ( <10 L )

4/6/8/9

cavities

2,400 ~ 16,000

bph

For PET

Daily Chemical

Bottles

4/6

cavities

2,400 ~ 4,200

bph

For PET Medicine Bottles / PET Agricultural Chemical Bottles

2/4/6

cavities

1,500 ~ 4,200

bph

FAQ

Question 1: How can we get the exact price of machine?

Answer:

Contact us with bottle volume, the diameter of bottle mouth, production capacity and the weight of bottle preform. Then we will recommend you the most suitable machine soon.

Question 2: Do you provide custom machines?

Answer:

Yes, we provide custom machines according to your bottle requirements.

Question 3: Do you provide any spare parts with machines?

Answer: Yes, we offer all necessary spare parts together with machines. After purchasing our machines, if you need new spare parts, send us message, we will arrange them within 24 hours by DHL/UPS service.

Answer: Yes, we offer all necessary spare parts together with machines. After purchasing our machines, if you need new spare parts, send us message, we will arrange them within 24 hours by DHL/UPS service.

Question 4: How about your after-sell service?

Answer:

We provide machine operation manual and engineer training before delivery. After the machine arrives at your factory, we provide 24 hours online support, video technical support or field installation assist. What's more, our machines can be installed easily, even though your workers do not have any experience.

Generally speaking, we will send an experienced engineer to your factory to guide the machine installation and on-site training if you need.

Question 5: How long is the delivery time?

Answer:

All machines have to go through strict inspection before they go out, so t

he delivery time usually takes one month after the order is confirmed.

Question 6: What's your guarantee or the warranty of the quality if we buy your machines?

Answer: We provide high-quality advanced machines with 1-year warranty and lifetime professional technical support to you.

Contact Us

Hot Searches