- Product Details

- {{item.text}}

Quick Details

-

Positioning Accuracy (mm):

-

0.03 mm

-

Travel (X Axis)(mm):

-

300 mm

-

Travel (Y Axis)(mm):

-

300 mm

-

Repeatability (X/Y/Z) (mm):

-

0.03 mm

-

Spindle Motor Power(kW):

-

10KW or 15KW HSD ATC Spindle

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SMARTECH

-

Voltage:

-

220V / 380V

-

Dimension(L*W*H):

-

Customized

-

Weight (KG):

-

2500

-

Working size:

-

2000x4000mm

-

transportation:

-

X/Y axis is rack gear,Z axis is screw

-

Maximum work rate:

-

15m/min

-

Spindle power:

-

5.5kw*3 water cooling spindle

-

Control system:

-

Nc Studio system

-

Driver:

-

China Servo motor

-

Working Voltage:

-

380V 50HZ

-

Cooling method:

-

Water-cooling

-

Machine Size:

-

3600*2800*2500mm

-

Weight:

-

About 2500kgs

Quick Details

-

Working Table Size(mm):

-

3000x3000

-

Machine Type:

-

CNC Router

-

Range of Spindle Speed(r.p.m):

-

18000 - 24000 rpm

-

Positioning Accuracy (mm):

-

0.03 mm

-

Travel (X Axis)(mm):

-

300 mm

-

Travel (Y Axis)(mm):

-

300 mm

-

Repeatability (X/Y/Z) (mm):

-

0.03 mm

-

Spindle Motor Power(kW):

-

10KW or 15KW HSD ATC Spindle

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SMARTECH

-

Voltage:

-

220V / 380V

-

Dimension(L*W*H):

-

Customized

-

Weight (KG):

-

2500

-

Working size:

-

2000x4000mm

-

transportation:

-

X/Y axis is rack gear,Z axis is screw

-

Maximum work rate:

-

15m/min

-

Spindle power:

-

5.5kw*3 water cooling spindle

-

Control system:

-

Nc Studio system

-

Driver:

-

China Servo motor

-

Working Voltage:

-

380V 50HZ

-

Cooling method:

-

Water-cooling

-

Machine Size:

-

3600*2800*2500mm

-

Weight:

-

About 2500kgs

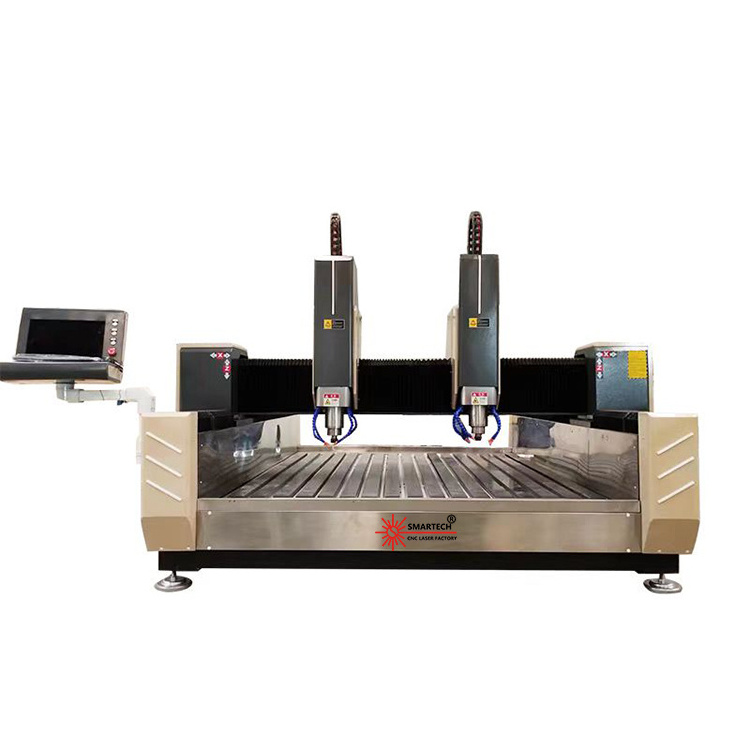

Product Description

|

working size(X*Y*Z)

|

1800*2500*400MM

|

|

transportation

|

X/Y axis is rack gear,Z axis is screw

|

|

Maximum work rate

|

15m/min

|

|

Spindle power

|

5.5kw*3 water cooling spindle

|

|

Control system

|

Nc Studio system

|

|

Driver

|

China Servo motor

|

|

Working Voltage

|

380V 50HZ

|

|

Cooling method

|

Water-cooling

|

|

Machine Size

|

3600*2800*2500mm

|

|

Weight

|

About 2500kgs

|

PS: All the working area and specifications can be customized according to your requests.

stone cutting and shaping machine Advantages:

1. The equipment has good and comprehensive safety protection measures. 2. Movable parts that are frequently adjusted and maintained. 3. Electrical safety standards, control system can ensure that there is no danger when the equipment is powered off, and the equipment itself and personnel will not be injured. 4. The electrical control system of the equipment has the functions of overload protection and short circuit protection.

1. The equipment has good and comprehensive safety protection measures. 2. Movable parts that are frequently adjusted and maintained. 3. Electrical safety standards, control system can ensure that there is no danger when the equipment is powered off, and the equipment itself and personnel will not be injured. 4. The electrical control system of the equipment has the functions of overload protection and short circuit protection.

stone cutting and shaping machine Application:

1. The equipment has good and comprehensive safety protection measures.

2. Movable parts that are frequently adjusted and maintained.

3. Electrical safety standards, control system can ensure that there is no danger when the equipment is powered off, and the equipment itself and personnel will not be injured.

4. The electrical control system of the equipment has the functions of overload protection and short circuit protection.

Nc Studio Control system

The data processing speed is fast, the operation is stable, the new man-machine screen, convenient keys, fast operation, easy to learn and use, reduce the development time of the machine, and at the same time ensure the accuracy of the equipment and high cost performance.

Main accessories

All well-known brands are used, with strong impact resistance, anti-interference, moisture resistance and stability, to ensure the equipment stable processing operation for a long time.

guide rail

High precision, long service life, large contact surface, strong load-bearing capacity, and high-precision helical racks can better ensure the stability of operation.

Assembly process

The whole machine adopts the second assembly process, in which the first assembly determines the mechanical accuracy, and the second assembly enters the quality inspection process. The entire bed body is subjected to aging treatment, and all cast iron parts are quenched and strengthened.

Packaging Details:

1. Outside package: Standard marine export plywood case.

2. Inner package: Three layers in total; EPE pearl cotton film+PE stretchy film.

Improved package, much more strong and environmental protection.

We can also make package according to your requests.

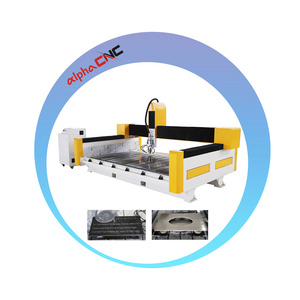

SIMILAR PRODUCTS

Hot Searches