- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

13500*3500*1600cm

-

Weight:

-

6500 KG, 6500kg

-

Product name:

-

Corrugated Carton Box Making Machine

-

Color:

-

as customer requirement

-

Power:

-

11.5kw

-

Folding way:

-

2 Folds

-

Speed:

-

100-180m/min

-

Function:

-

paperboard folding and gluing

-

Usage:

-

carton box making

-

Box forming:

-

Sides Fold

-

Installation Area:

-

15500*3500*1600 mm

Quick Details

-

Voltage:

-

220V/380V/415V/440V

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZHENHUA

-

Dimension(L*W*H):

-

13500*3500*1600cm

-

Weight:

-

6500 KG, 6500kg

-

Product name:

-

Corrugated Carton Box Making Machine

-

Color:

-

as customer requirement

-

Power:

-

11.5kw

-

Folding way:

-

2 Folds

-

Speed:

-

100-180m/min

-

Function:

-

paperboard folding and gluing

-

Usage:

-

carton box making

-

Box forming:

-

Sides Fold

-

Installation Area:

-

15500*3500*1600 mm

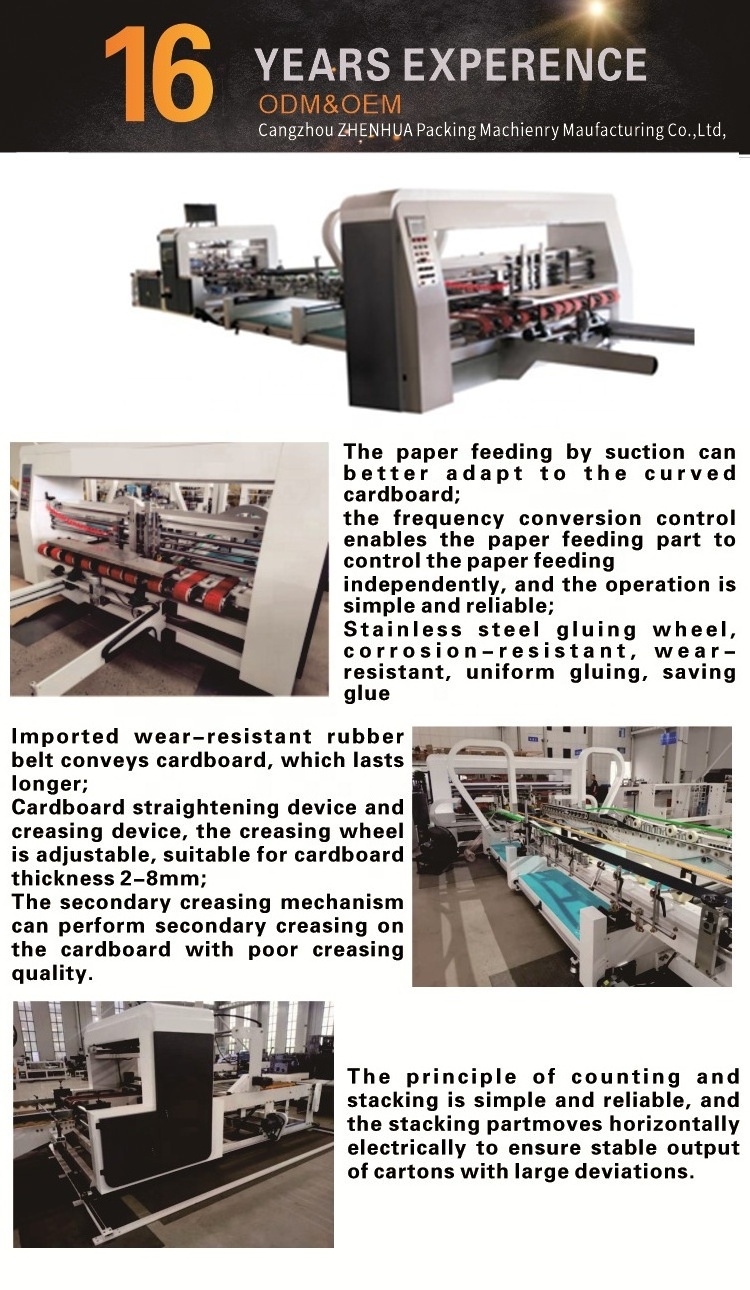

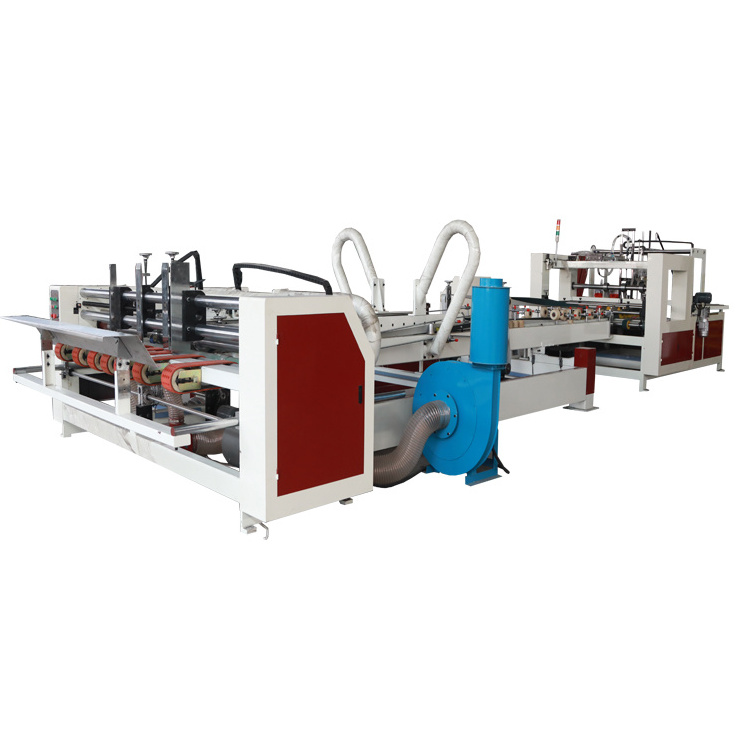

ZHENHUA QZD Good Quality Fully Automatic Cardboard Pasting Folder Gluer Machine For Making Corrugated Carton Box

Product Description

Automatic glue machine is consist of three parts ,which is paper feeding part ,gluing and folding part and counting and stacking part. Automatic paper feeding ,automatic fold and glue,automatic counting and stacking output,The operation is simple and reliable. The speed can reach 100-180 pieces per minute. Advanced and reasonable structure design and manufacture, it demands for cultural level of operators is not high, and operators will be able to handle all operating procedures in one or two working days, and protect the safety of operating personnel.

|

Model

|

QZD-2400

|

QZD-2600

|

QZD-2800

|

Min Box

|

|

Size A(mm)

|

130-880

|

130-880

|

130-880

|

130-880

|

|

Size B(mm)

|

700-2400

|

700-2600

|

700-2800

|

420-2300

|

|

Size C(mm)

|

160-840

|

160-840

|

160-840

|

160-840

|

|

Size D(mm)

|

260-1050

|

260-1050

|

260-1050

|

170-1050

|

|

Install Size(mm)

|

3500×14000

|

4200×15000

|

4500×16000

|

3500×14000

|

|

Main Power(kw)

|

10kw

|

12kw

|

12kw

|

10kw

|

Machine Detail

Characteristic and Function Explanation of ZH-QZD Fully Automatic Box Folder Gluer Machine:

The whole machine features of fully automatic box-Folder Gluer machine:

ZH-QZD Series Fully Automatic Box Folder Gluer Machine consists of vacuum paper feeding part, glue coating part and counting stacked output part. Data regulation,PLC computer banner, double frequency conversion synchronous operation, with a simple, fast,reliable and accurate operation mode. Automatic paper feeding, automatic Glue folding, automatic counting, automatic pushing output, the average speed of Folder Gluer box 150 meters per minute, high efficiency and energy saving, saving labor costs.

Introduction to the functions of all parts of the automatic box-Folder Gluer machine:

1. Paper Supply Department

★ The belt leading edge suction paper feeding method is accurate and reliable.

★ Using high-grade electromagnetic clutch and brake system, the paper supply department can be controlled separately, and the

operation is simple and reliable.

★ The height of the press wheel is adjustable, suitable for 2-8mm cardboard thickness.

★ Linkage with folding part, variable frequency speed regulation, paper feeding speed 0-130M/MIN.

★ The front baffle and the paper belt of the paper supply department can be adjusted left and right.

2.Glue-coated folding part

★The main motor adopts frequency conversion speed regulation, the system has no noise, the speed regulation is flexible and

stable.

★ The imported high friction belt is used to convey cardboard, which is automatically overlapped.

★ The stainless steel wheel is coated with glue, which has uniform glue content, no trouble and saves glue.

★The folding part is equipped with cardboard correction device and indentation correction device.

★ The folding part has two rows of adjustable inner positioning guide wheel system, which has higher forming accuracy.

★ Folding speed 0-130M/MIN

★ Motor brake regulation left and right archway.

3.Counting accumulation part:

★Using PLC programming control and touch screen digital control, the operation is simple, reliable and non-stop input

data,automatic counting, automatic stacking, neat output.

★ The main motor of the counting unit can be adjusted by frequency conversion and speed, and the start-up is stable and reliable.

★ Conveying cartons with belt, neat stacking, speed regulation 0-130M/MIN

★ It has the function of rectifying deviation and little deviation by beating cartons.

★Counting and pushing paper adopt pneumatic mode, PLC point control, reliable action, accurate and fast.

★The output part adopts synchronous pressing mode of bottom conveyor belt and upper pressing belt, so that the finished carton is

firmly adhered and neat without dislocation. Paper stacking height is 8-25 sheets.

4.Other:

★Folding part main motor 4KW adopts frequency conversion speed regulation.

★Main motor of counting stacking part 2.2KW adopts frequency conversion speed regulation.

★Main motor of folded amplitude modulation unit ,Two 0.4KW brake motors.

★Output main motor four 0.1KW gear reducer motors.

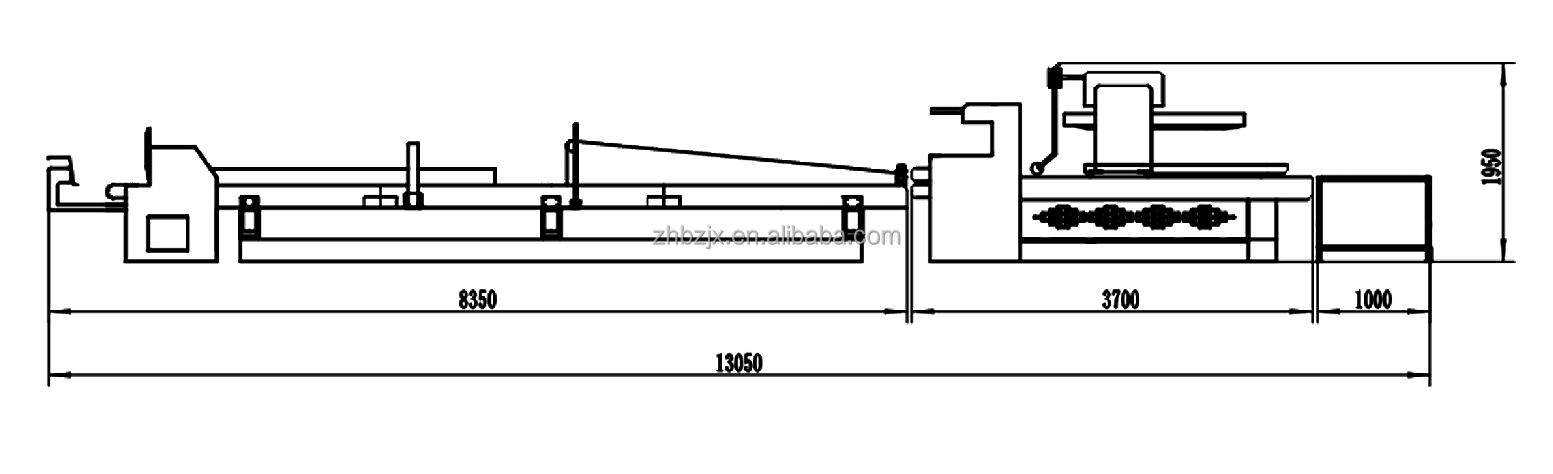

Mechanical dimensions: 2800*13050*1960

Weight: 5 tons

Total power supply: 380V 11.4KW, especially energy-saving.

1. Paper Supply Department

★ The belt leading edge suction paper feeding method is accurate and reliable.

★ Using high-grade electromagnetic clutch and brake system, the paper supply department can be controlled separately, and the

operation is simple and reliable.

★ The height of the press wheel is adjustable, suitable for 2-8mm cardboard thickness.

★ Linkage with folding part, variable frequency speed regulation, paper feeding speed 0-130M/MIN.

★ The front baffle and the paper belt of the paper supply department can be adjusted left and right.

2.Glue-coated folding part

★The main motor adopts frequency conversion speed regulation, the system has no noise, the speed regulation is flexible and

stable.

★ The imported high friction belt is used to convey cardboard, which is automatically overlapped.

★ The stainless steel wheel is coated with glue, which has uniform glue content, no trouble and saves glue.

★The folding part is equipped with cardboard correction device and indentation correction device.

★ The folding part has two rows of adjustable inner positioning guide wheel system, which has higher forming accuracy.

★ Folding speed 0-130M/MIN

★ Motor brake regulation left and right archway.

3.Counting accumulation part:

★Using PLC programming control and touch screen digital control, the operation is simple, reliable and non-stop input

data,automatic counting, automatic stacking, neat output.

★ The main motor of the counting unit can be adjusted by frequency conversion and speed, and the start-up is stable and reliable.

★ Conveying cartons with belt, neat stacking, speed regulation 0-130M/MIN

★ It has the function of rectifying deviation and little deviation by beating cartons.

★Counting and pushing paper adopt pneumatic mode, PLC point control, reliable action, accurate and fast.

★The output part adopts synchronous pressing mode of bottom conveyor belt and upper pressing belt, so that the finished carton is

firmly adhered and neat without dislocation. Paper stacking height is 8-25 sheets.

4.Other:

★Folding part main motor 4KW adopts frequency conversion speed regulation.

★Main motor of counting stacking part 2.2KW adopts frequency conversion speed regulation.

★Main motor of folded amplitude modulation unit ,Two 0.4KW brake motors.

★Output main motor four 0.1KW gear reducer motors.

Mechanical dimensions: 2800*13050*1960

Weight: 5 tons

Total power supply: 380V 11.4KW, especially energy-saving.

Finished Products

Packaging And Shipping

Hot Searches