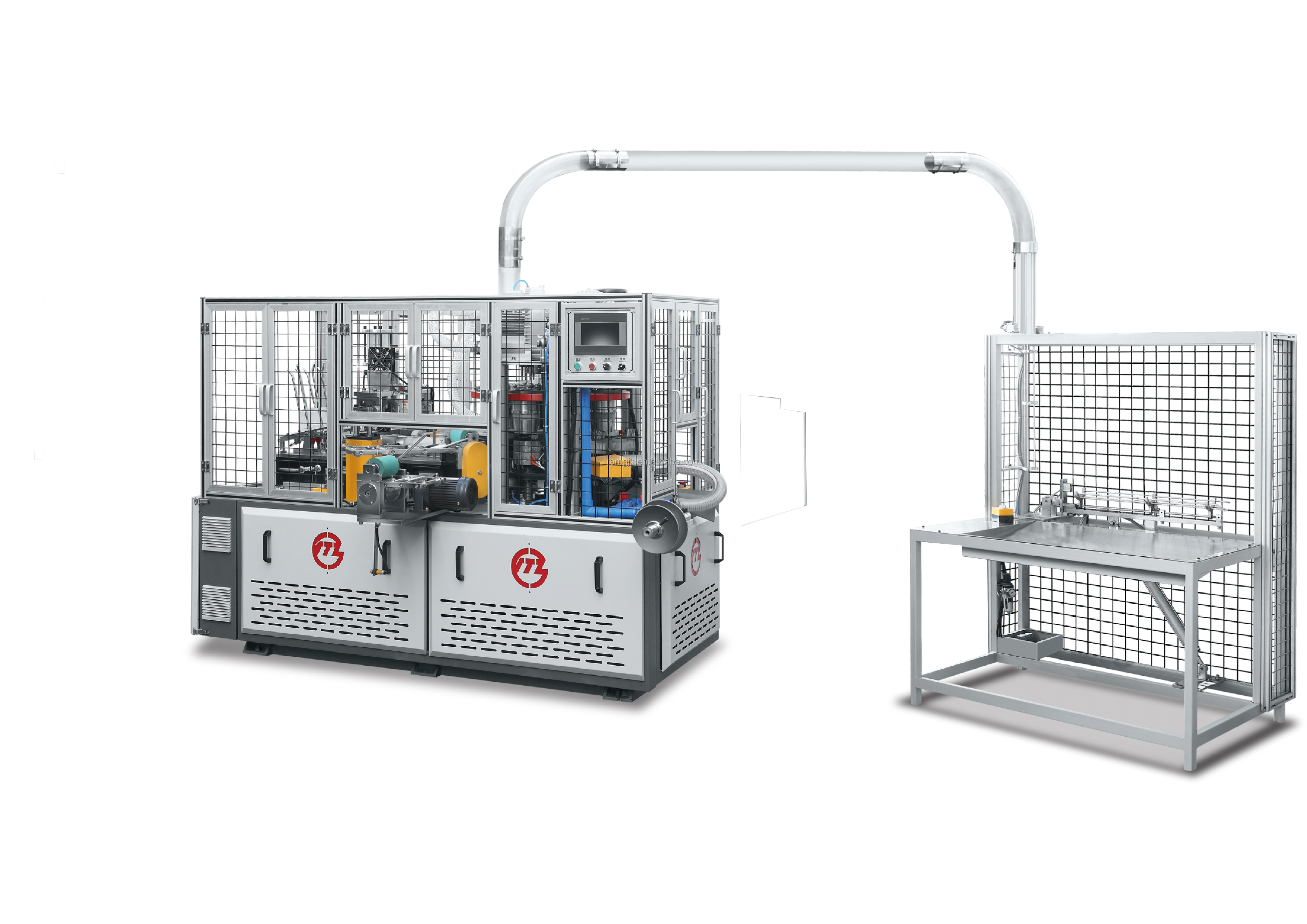

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V 50Hz/60Hz

-

Power:

-

8KW

-

Dimension(L*W*H):

-

2600*1200*1700mm

-

Weight:

-

3000KG

-

speed:

-

60-80 piece/minite

-

After-sales Service Provided:

-

Overseas service center available, Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Online support

Quick Details

-

Production Capacity:

-

60-80PCS/MIN

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

MINGGUO

-

Voltage:

-

220V/380V 50Hz/60Hz

-

Power:

-

8KW

-

Dimension(L*W*H):

-

2600*1200*1700mm

-

Weight:

-

3000KG

-

speed:

-

60-80 piece/minite

-

After-sales Service Provided:

-

Overseas service center available, Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Online support

Workshop

CERTIFICATE

PACKAGING WITH THE WOODENCASE

FAQ

Yes,We have been in making paper cup machine for nearly 7 years We have our own workshop,

and nearly 80 workers here.

2:What about the payment term ?

Mostly 30%T/T in advanced,the rest need paid before shipping.

3:Where is your factory location?

We Are Location In Feiyun District ,Feiyun Street Ruian City,Zhejiang Province,China

4:How's your after-sale service?

we offers one year warrantyr and we can send to you freely if there is any spare part broken because of our reason.

Our engineers can also go to your factory to install machines and train your workers.

5:What about the Delivery time?

Within 40-50 days after receipt of advance payment and cup sample