- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

QISHENG

-

Voltage:

-

380v 3 phases or Customized

-

Power (kW):

-

30

-

Weight (T):

-

1.3

-

Application:

-

plastic rubber metal recycling shredding

-

Product Name:

-

foam cardboard single/double shaft shredder machine

-

Raw material:

-

Plastic Products Paper Wood Metal Product

-

Shaft:

-

Double shaft

-

Final size:

-

2-10CM

Quick Details

-

Max.Production Capacity (kg/h):

-

10000

-

Place of Origin:

-

Henan, China

-

Production Capacity (kg/h):

-

800 - 1500 kg/h

-

Brand Name:

-

QISHENG

-

Voltage:

-

380v 3 phases or Customized

-

Power (kW):

-

30

-

Weight (T):

-

1.3

-

Application:

-

plastic rubber metal recycling shredding

-

Product Name:

-

foam cardboard single/double shaft shredder machine

-

Raw material:

-

Plastic Products Paper Wood Metal Product

-

Shaft:

-

Double shaft

-

Final size:

-

2-10CM

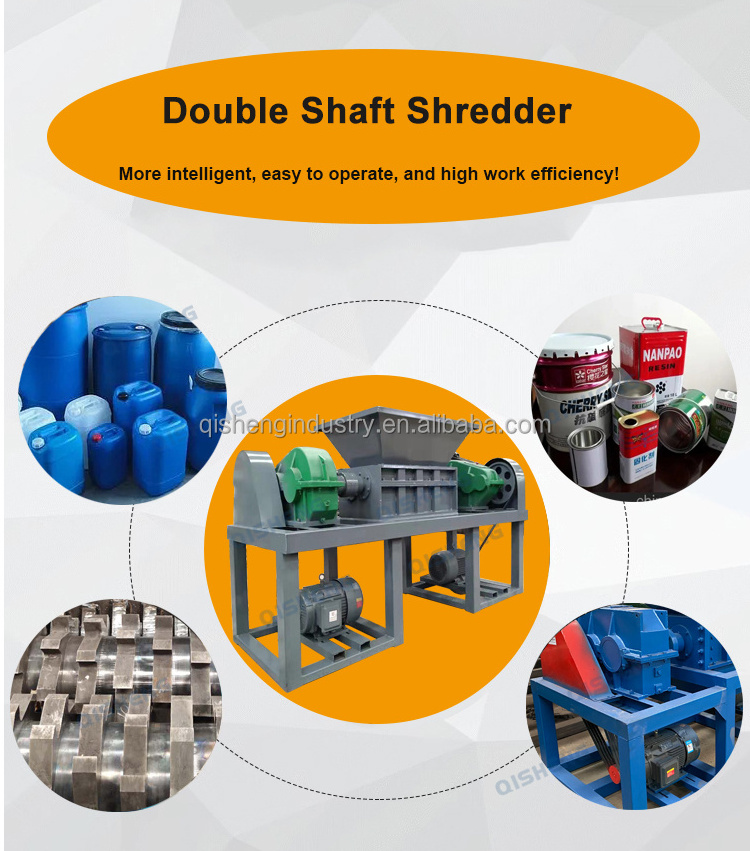

Plastic Recycling copper cable shredder machine plastic shredder small foam cardboard single/double shaft shredder machine

Product Description

Introduction:

Double Shaft shredder can shred common garbage in life, such as wood, straw, plastic, metal, rubber glue, fruit and vegetable waste, food waste, various fabrics, etc., can be divided into RDF materials that can be used as fuel (i.e.waste-derived fuels), recyclable materials (plastics, metals, non-ferrous metals, etc.), and residual materials (usually used as landfills).

Application:

1, All kinds of hollow containers: plastic beverage cans, plastic buckets, iron buckets, packing boxes, packing barrels

2, Waste appliances: TV, washing machine, refrigerator shell

3, Pipe: large pipe, pipe fittings, PE pipe

4, Waste template: wood pallet, plastic pallet, forklift pallet

5, Used tires: car tires, truck tires

6, Scrap metal: car shell, aluminum alloy, scrap cast aluminum parts, engine shell, lead and thickness of steel plate in 5mm below

7,Food waste, household waste, animal carcasses, RDF derivatives, medical waste, biological orange sticks, garden waste ,plastic head material, paper factory rope,etc

The working principle of the shredder:

The material enters the inside of the shredder box through the feeding system, and the box is supported on the top.

The blade of the shredder is loaded, and the material is torn, squeezed, and sheared by the blade of the shredder. Used, shredded into small pieces of material, discharged from the lower part of the box.

Structure features:

1. Main body of crusher:

The main body of the equipment adopts high quality steel plate welding to eliminate stress treatment/integral machining to ensure the stability of the equipment in long time heavy load.

2, Moving knife/fixed knife:

The moving knife material is made of special special alloy tool steel forged blank, precision machining, multiple heat treatment and cryogenic heat treatment technology. The overall toughness and hardness can be repaired repeatedly to ensure the cutting performance and service life. Fixed knife adopts hook type installation, optimizing tool replacement function, making tool maintenance and replacement more efficient.

3, Bearing/seal:

the bearing seat adopts the split and disassembly type, can quickly remove the moving knife, fixed knife, bearing and other parts, easy to maintain and replace the tool, the unique sealing structure effectively block the contact of broken materials and grease, processing liquid materials can also protect bearings and gears, etc..

4, tool shaft:

The use of high strength heavy duty special steel processing refined, more reasonable with the tool to provide powerful power for cutting.

Paratemers:

|

Model

|

Motor Power

|

Reducer model

|

Rotating Speed(rpm/min)

|

Overall Size(m)

|

|||

|

QS-400

|

12KWx2

|

ZQ320x2

|

16-24

|

1.4*0.7*1.85

|

|||

|

QS-600

|

15KWx2

|

ZQ400x2

|

18-25

|

1.45*0.87*2.2

|

|||

|

QS-800

|

15-30KWx2

|

ZQ500x2

|

18-25

|

2.15*0.87*2.2

|

|||

|

QS-1000

|

30KWx2

|

ZQ650x2

|

18-25

|

3.4*1.25*2.2

|

|||

|

QS-1200

|

55KWx2

|

ZQ650x2

|

18-25

|

4.15*1.25*2.2

|

|||

|

Remarks

|

Above data is just for reference,machine is customized ,different materials and final request size different,please based on final data

|

|

|

|

|||

Recommend Products

Packing & Delivery

Packing: Nude or plywood case or as request

Delivery Date: 7-30 days after confirm the down payment according to order quantity and buyer's request.

Shipping Method: By sea

Shipping Port: Qingdao, China

Why Choose Us

♦Pre-sales:

1 Perfect 7*24hours inquiry and professional consulting service

2.Visit our factory anytime

♦Sale:

1. Update the production schedule in time

2. Quality supervision

3. Product acceptance

4. Shipping on time

♦After-sales:

1. Guarantee:1 year ,during this period we will offer free spare parts if they are broken.

2. Training how to install and use machine

3. Engineers available to service overseas

4. Skill support during the whole using life

Hot Searches