Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Zhend, 19-YEAR Composite Panels China Manufacturer

-

Model Number:

-

Fiberglass Laminate Panel

-

No.1 Core material:

-

Polyurethane or PU Core Sandwich Panels

-

No.2 Core material:

-

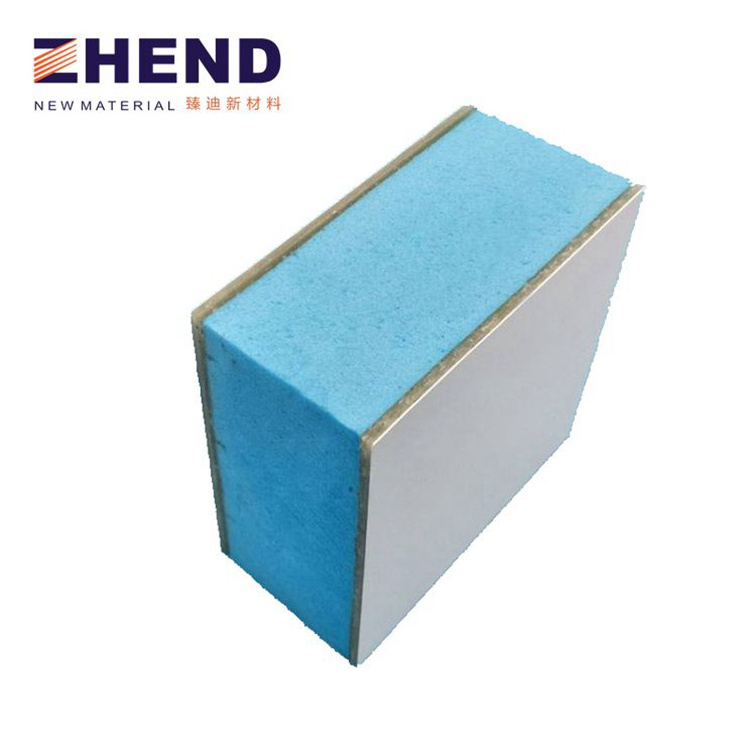

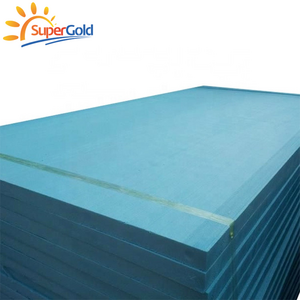

XPS, Extrude Polystyrene Form Sandwich Panels

-

No.3 Core material:

-

Composite Honeycomb Sandwich Panels

-

Thickness of Core:

-

5-100MM

-

Fiberglass Skin:

-

1-3MM

-

Width:

-

100-2700MM

-

Length:

-

Customized

-

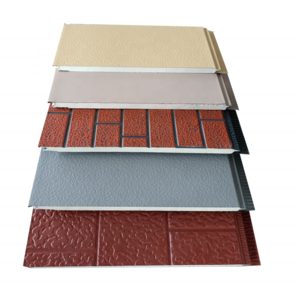

Color:

-

RAL Color

-

Features:

-

High Impact with Light Weight

Quick Details

-

Project Solution Capability:

-

3D model design, total solution for projects

-

Application:

-

Warehouse

-

Design Style:

-

industrial

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Zhend, 19-YEAR Composite Panels China Manufacturer

-

Model Number:

-

Fiberglass Laminate Panel

-

No.1 Core material:

-

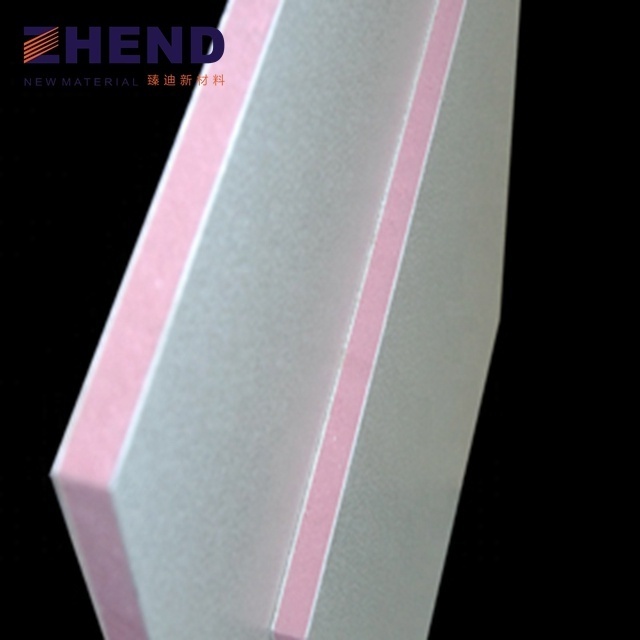

Polyurethane or PU Core Sandwich Panels

-

No.2 Core material:

-

XPS, Extrude Polystyrene Form Sandwich Panels

-

No.3 Core material:

-

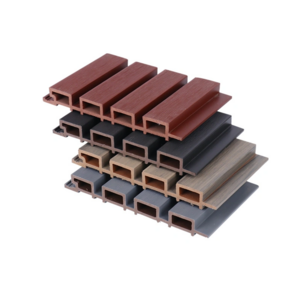

Composite Honeycomb Sandwich Panels

-

Thickness of Core:

-

5-100MM

-

Fiberglass Skin:

-

1-3MM

-

Width:

-

100-2700MM

-

Length:

-

Customized

-

Color:

-

RAL Color

-

Features:

-

High Impact with Light Weight

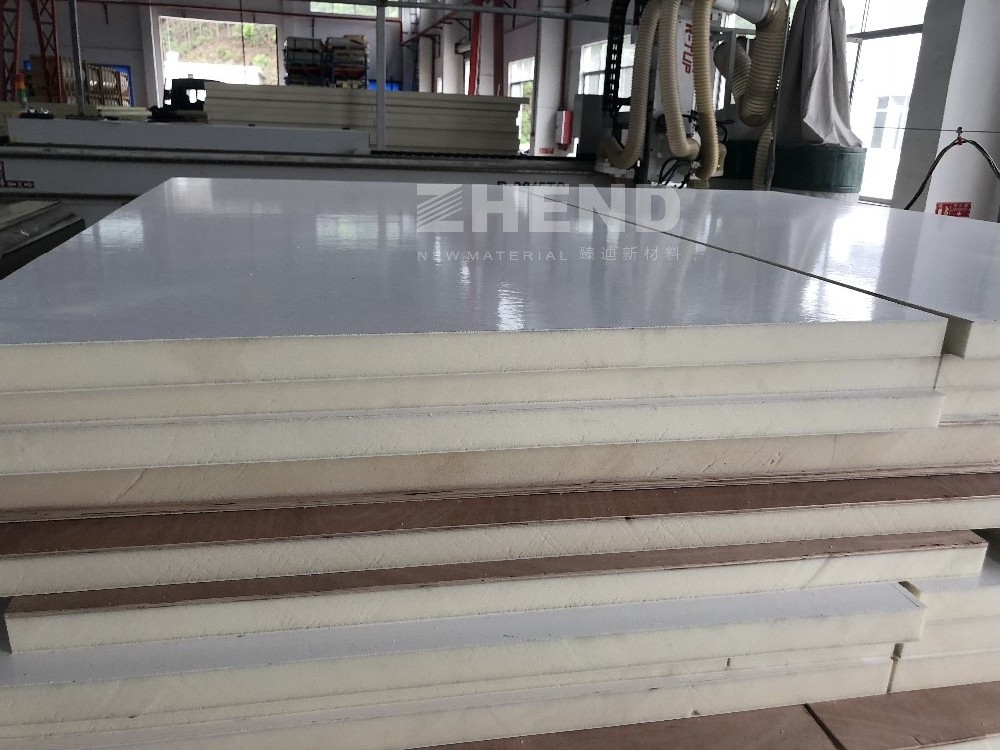

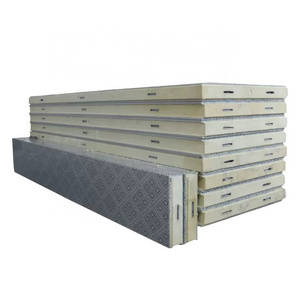

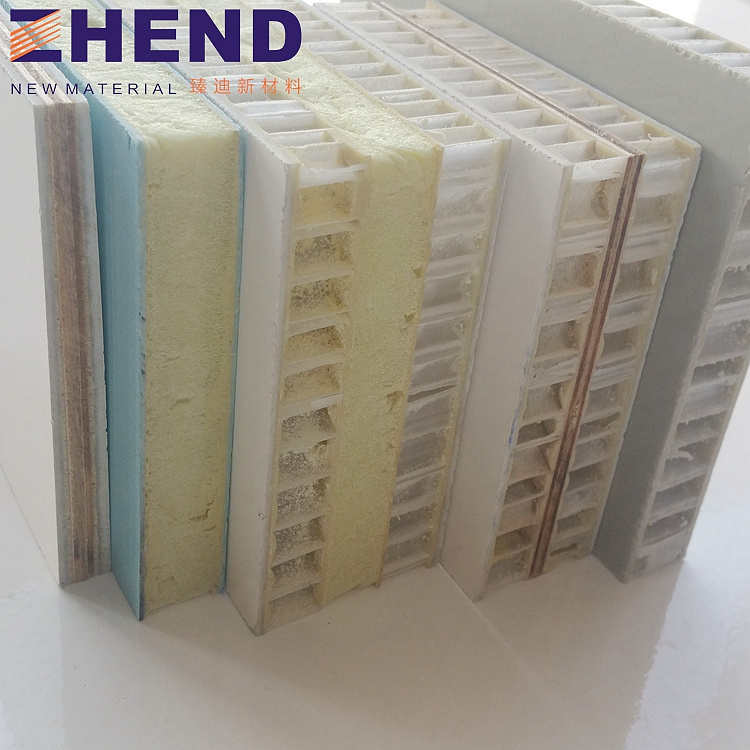

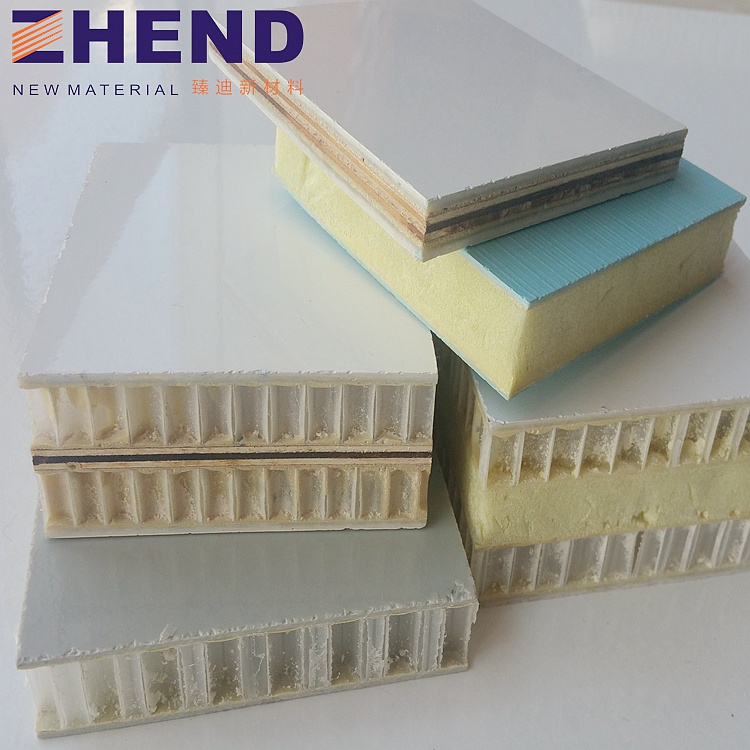

Easy install best price XPS sandwich panels for trailer and bus side wall

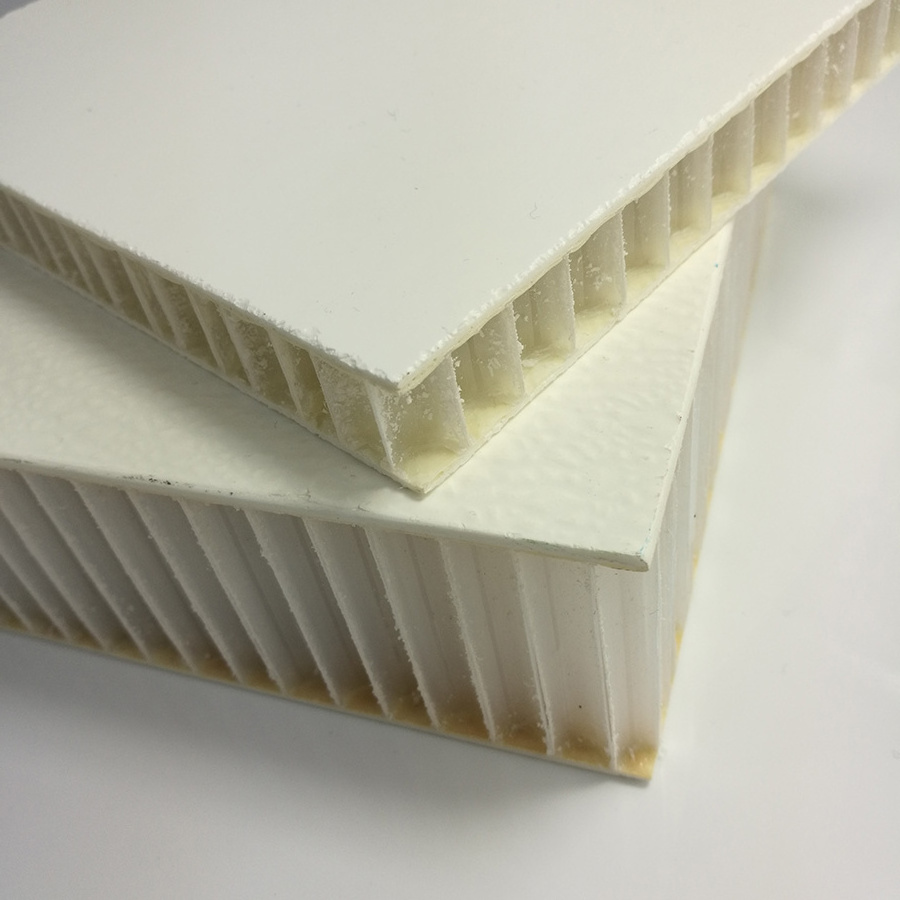

FRP Sandwich panels for truck body offer higher strength-to-weight ratios than solid composite laminates alone. The materials used in a sandwich composite panel consist of thin, lightweight composite laminate facings or skins, such as fiberglass or carbon fiber , and a lightweight, low-density core . These are bonded together in a wet lay-up process, wet lay-up and vacuum bagged, prepreg and oven cured, or in a post process bonding application where cured composite skins are bonded to a core using a resin film adhesive , vacuum bagged and oven cured.

Separating the fiberglass skins with a foam core delivers greater strength properties than those of the skins alone. The fiberglass skins offer high strength-to-weight ratio, thermal and electrical conductivity, high tensile strength, low density, low weight, low thermal expansion and excellent fatigue resistance.

Main Features:

- Combines multiple materials to create a unique material

- Lighter structures

- Enhanced mechanical properties

- High strength

- High stiffness

- Design flexibility

- Thermal insulation

- Very durable

Types of Core of Insulated Panels:

|

ITEM | FRP XPS Sandwich Panel |

| Core Material | XPS, Extrude Polystyrene | |

| Fiberglass Sheet Skin |

1-3MM |

|

| Core | 10-100MM | |

| Width | ≤2700MM | |

| Length | ≤12000MM |

|

ITEM | FRP PP Honeycomb Panel |

| Core Material | PP Honeycomb | |

| Fiberglass Sheet Skin | 1-3MM | |

| Core | 5-100MM | |

| Width | Max 2700MM | |

| Length | Max 12000MM |

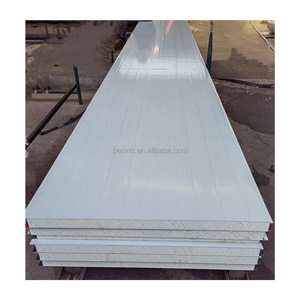

| ITEM | FRP PU Sandwich Panel | |

| Core Material | PU Foam, Polyurethane Foam | |

| Fiberglass Sheet Skin | 1-3MM | |

| Core | 10-100MM | |

| Width | Max 2700MM | |

| Length | Max 12000MM |

| ITEM | FRP Plywood Sandwich Panel | |

| Core Material | Plywood panel | |

| Fiberglass Sheet Skin | 1-3MM | |

| Core | 3-20MM | |

| Width | Max 1220MM | |

| Length | Max 2440MM |

>> Refrigerator Van & Truck Body

>> Sentry box & Mobile Toilets

>> Caravan & RV Panel

>> Compartment & Partition Wall

>> Cattle Sheep Shed & Dog Kennel

Main Advantages of Our Company:

1. 19-YEAR FRP Sheet making machines manufacturer in China Has the latest production machines and production technology, thus ensure you get the best FRP products.

2. We have two production lines, one for the width less than 1500MM and the other for the width less than 3200MM. And the annual production capacity is more than 3,000,000SQ.M.

3. With ISO 9001:2005 Quality Management System Certificate approved, we have the strict quality control system from the raw material to the finished products.

Quality Control System:

|

Raw Material |

Choose Quality Supplier, Test it before Entering the Warehouse |

|

Mould |

Confirm the Size of Mould before production and Ensure the precision of the Design |

|

Experienced Workers |

Every Part has different workers to operate |

|

Production Machines |

Adjust the Temperature into the Appropriate Value and the Thickness and Speed |

|

Finished Product |

Test it before Entering the Warehouse and UN-qualified Product not Sold |

Our Production Line:

Our Office and Workshop:

Our Samples Cabinet:

Our Exhibition:

Welcome to Contact us for More Truck Body Panels Solutions!