- Product Details

- {{item.text}}

Quick Details

-

Welding Mode:

-

Seam welding

-

Welding Diameter:

-

1250mm

-

Dimensions:

-

1.0+1.0mm

-

Use:

-

Duct seam welding machine

-

Voltage:

-

220V/380V/440V/480V

-

Weight (KG):

-

800 KG

-

Welding direction:

-

Horzontal and lognitudinal

-

Material thickness:

-

1.2mm

-

Arm length:

-

1000mm

-

Wire diameter:

-

2.0mm-2.5mm

-

Welding material:

-

Thin-galvanized Sheets

-

Dimension:

-

2.6m*0.9m*1.3m

-

Function:

-

stitch welding/seam welding

-

Air flow:

-

250L/min

-

Weight:

-

800kg

-

Power:

-

4kw

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BOBO

-

Forming Time:

-

3-5S

-

Welding Mode:

-

Seam welding

-

Welding Diameter:

-

1250mm

-

Dimensions:

-

1.0+1.0mm

-

Use:

-

Duct seam welding machine

-

Voltage:

-

220V/380V/440V/480V

-

Weight (KG):

-

800 KG

-

Welding direction:

-

Horzontal and lognitudinal

-

Material thickness:

-

1.2mm

-

Arm length:

-

1000mm

-

Wire diameter:

-

2.0mm-2.5mm

-

Welding material:

-

Thin-galvanized Sheets

-

Dimension:

-

2.6m*0.9m*1.3m

-

Function:

-

stitch welding/seam welding

-

Air flow:

-

250L/min

-

Weight:

-

800kg

-

Power:

-

4kw

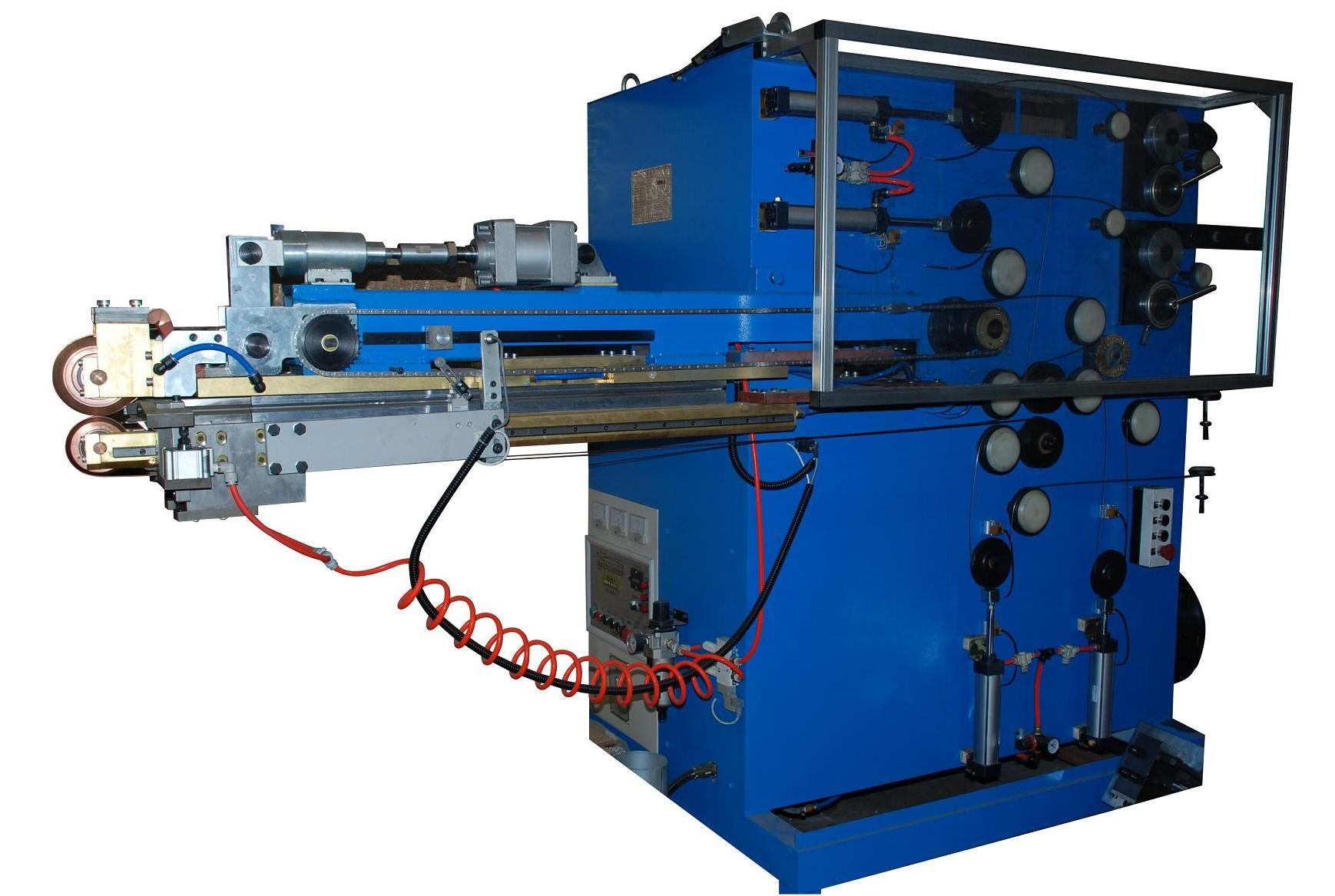

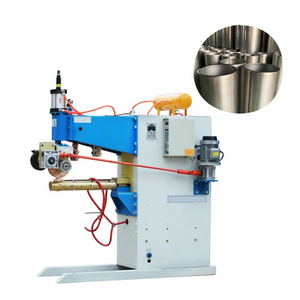

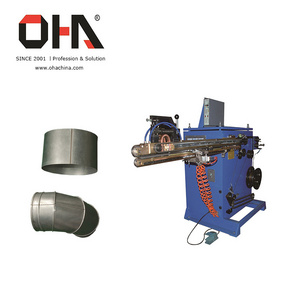

Product Application

This machine is a semi automatic stitchseam welding machine, designed for welding round duct / pipe / drums in large diameter range. Based on the seam welding machines, this machine is a special one whose electrode arms are lengthened to weld HVAC pipes. It is controlled by PLC and easy to operate.

|

SPECIFICATIONS FOR 25 TON CRAWLER EXCAVATOR

|

|

|

|

|||

|

Power

|

power

|

KW

|

4

|

|||

|

|

Air consumption

|

L/min

|

250

|

|||

|

|

Cooling water flow

|

L/min

|

8.5

|

|||

|

Main performance parameters

|

Materials' thickness

|

Tin, substrate iron≤1.2mm

|

galvanized plate≤1mm

|

|||

|

|

pipe size

|

mm

|

100-1000

|

|||

|

|

Max. Gradeability

|

rpm

|

11.3

|

|||

|

Other

|

Cooling water temperature

|

℃

|

≤25

|

|||

|

|

Dimension

|

mm

|

2.6m×0.9m×1.3m

|

|||

|

|

Air pressure

|

Mpa

|

0.5

|

|||

Main Features

☆ Large diameter range: 80mm~1000mm (5"~59")

☆ High production efficiency

☆ Good welding quality because of adopting double-wire technology

☆ Reasonable structure and simple maintenance: compact structure; welding electrodes and main driving mechanism are of simple assembly.

☆ Fast change welding pipe diameter

☆ PLC & inverter control the welding speed and stitch welding pitch

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

Shipping:

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like to have seamless cooperation with your forwarder at your convenience.

A: The standard power supply in china is 380V, 3P, 50Hz. We also can customized accordingly.

2. Q: What information should the customer provide to get an accurate quotation from us?

A: The customer should provide the related technical requirements, drawings, pictures, industrial voltage, planned output, etc

3. Q: What is the payment term A: The payment term is 30% down payment, and 70% before shipment(T/T mode), we also accept other payment term, like L/C, DA, D/P etc

4. Q: What is the delivery time?

A: Normally the delivery time of the machine is 30 days after receive down payment.

5. Q: What is the warrantee period of the machine?

A: The warrantee period is one year since the date of B/L.